High-pressure-resistant high-precision temperature sensor

A temperature sensor, high-precision technology, applied in the field of sensors, can solve the problems of low sensor sensitivity, error in detection results, long response time, etc., to achieve the effect of fast thermal response, guaranteed accuracy, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

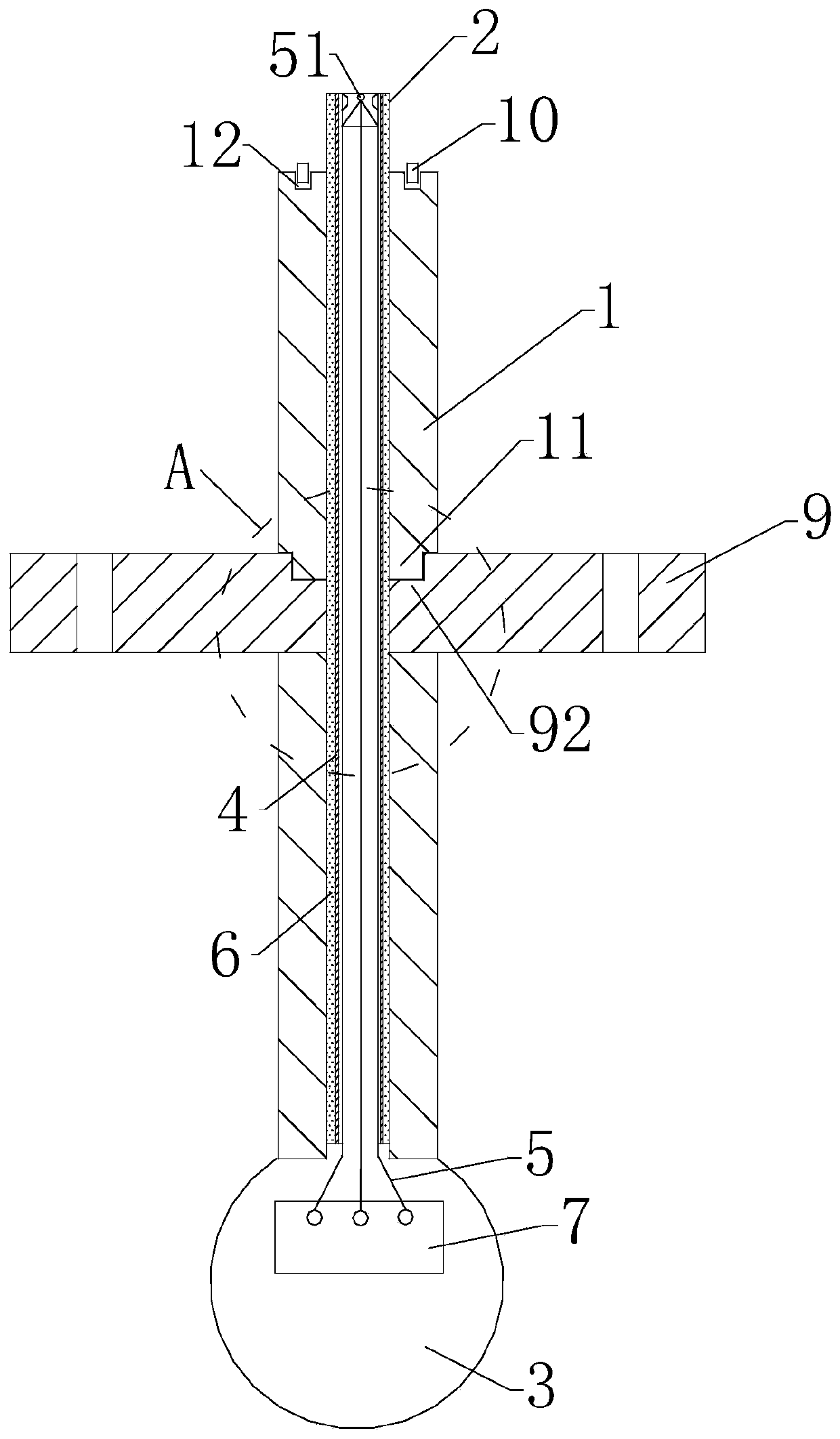

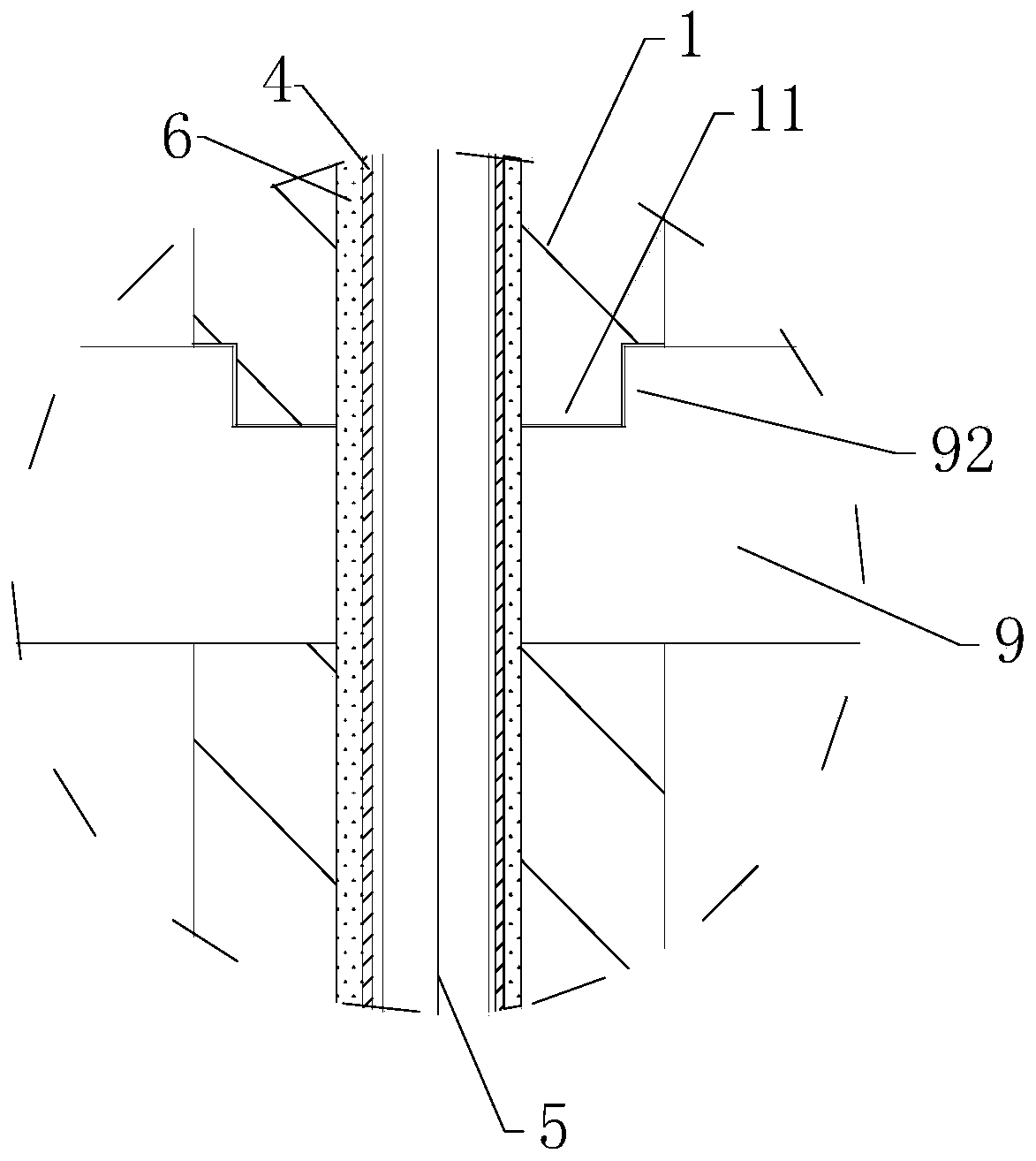

[0020] In the following, the present invention will be described in detail and completely through specific embodiments in conjunction with the accompanying drawings.

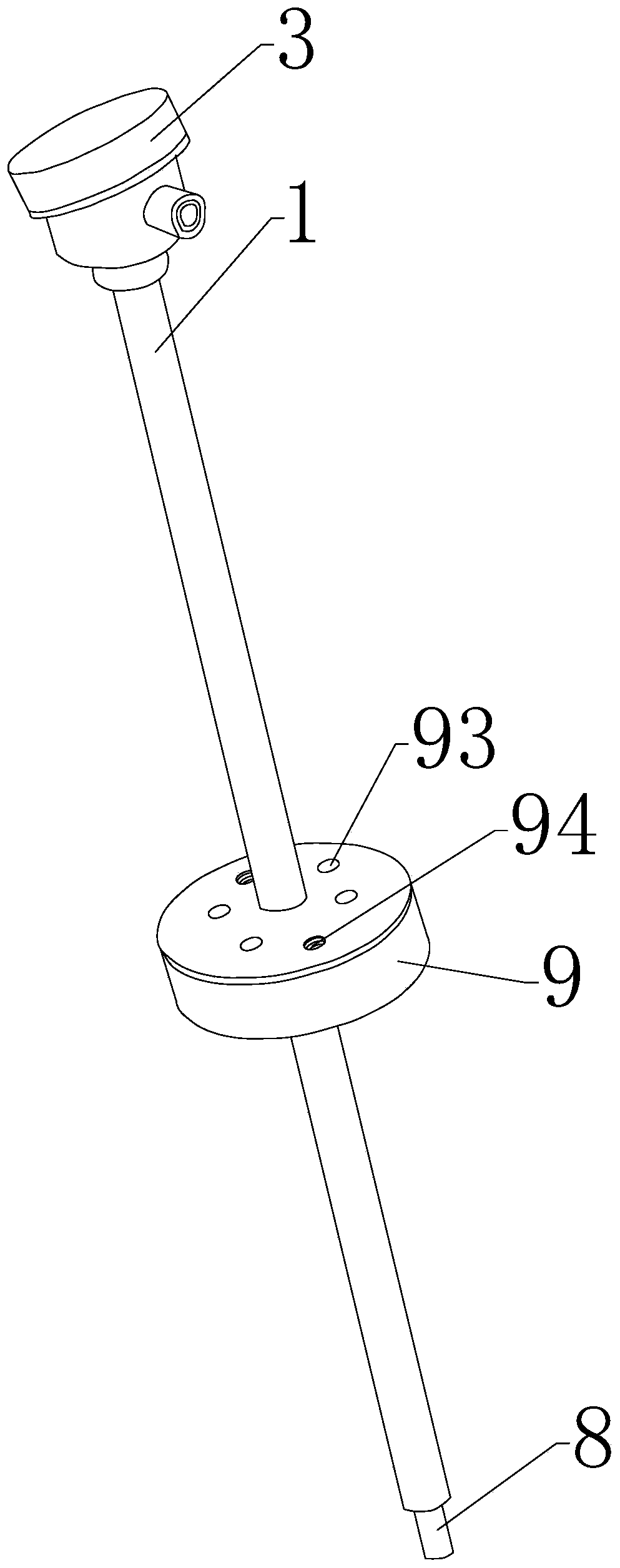

[0021] Please refer to Figure 1-3 As shown, the present invention provides a high-pressure high-precision temperature sensor, including an outer protective tube 1, an inner protective tube 2, a junction box 3, an insulating support 4, several conductive wires 5 and insulating fillers 6, and the junction box 3 is provided with At one end of the outer protection tube 1, a transmitter 7 is arranged in the junction box 3, the transmitter 7 is used to convert the temperature signal into an output signal, the inner protection tube 2 is inserted in the outer protection tube 1, and the inner protection tube 2 Extend from the other end of the outer protective tube 1 to form a detection probe 8, the insulating bracket 4 is set in the inner protective tube 2, and several conductive wires 5 are set in the insulating bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com