High-pressure gas long pipe semitrailer back-end integration bus bar

A technology of high-pressure gas and busbars, which is applied in the directions of gas/liquid distribution and storage, container discharge methods, container filling methods, etc., to achieve the effects of ensuring regular sewage discharge operations, increasing service life, and improving sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

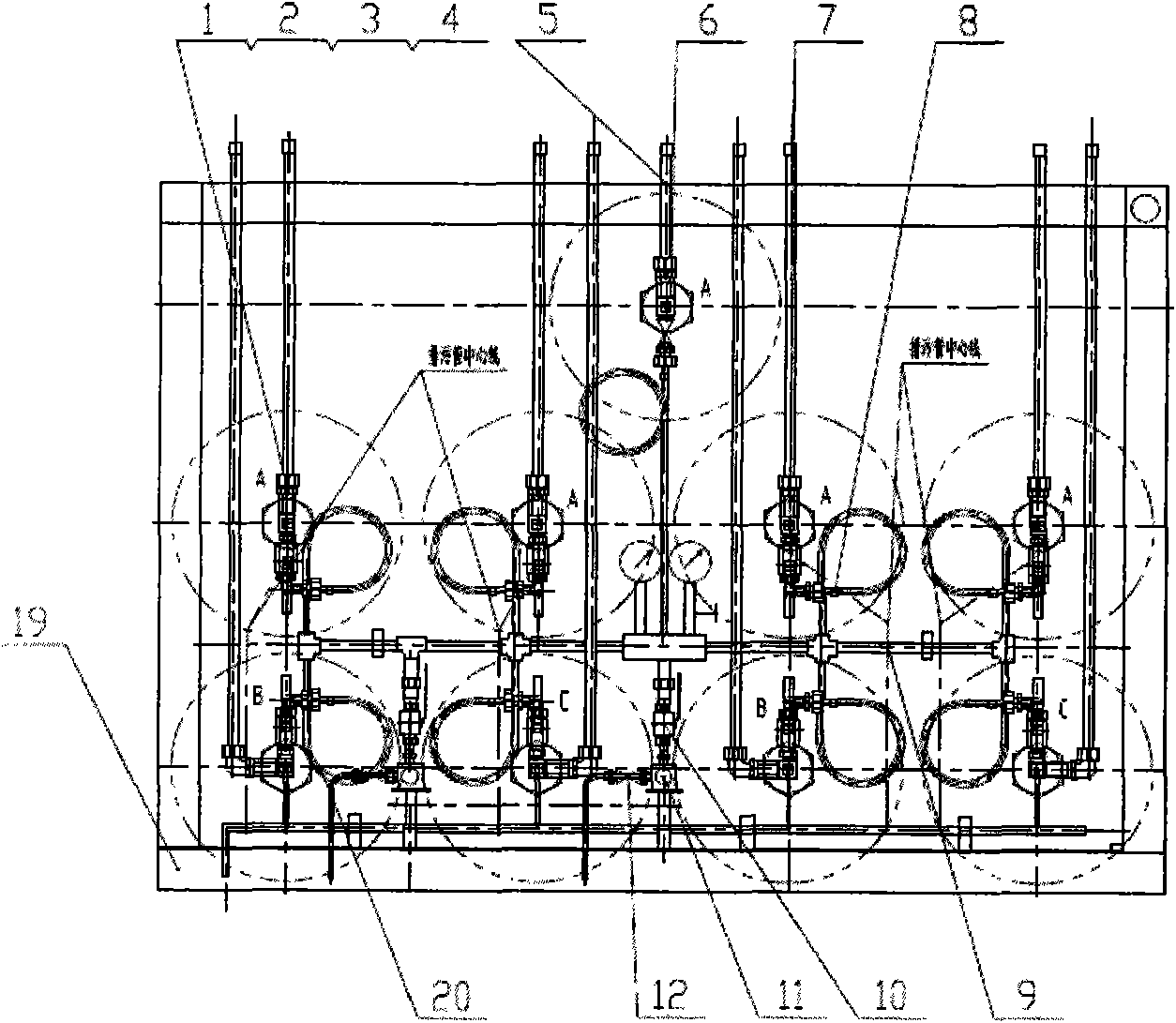

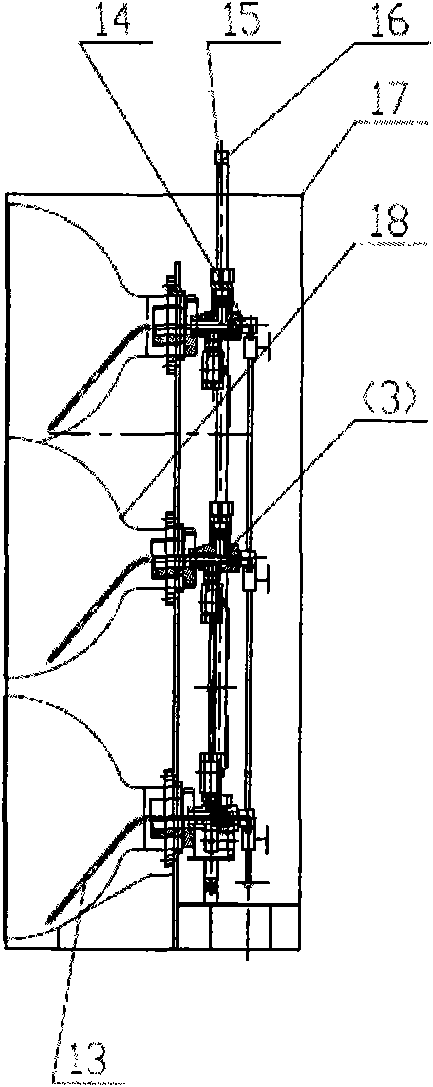

[0040] Figure 1 to Figure 12 It is a specific embodiment of the present invention.

[0041]The present invention includes: including: rear end plug 1, O-shaped sealing ring 2, K-shaped retaining ring 3, safety device 4, vent pipe 5, flared end straight-through pipe joint 6, NPT1 / 2" in and out balloon valve 7, Cone seal welded joint 8, summing pipe 9, NPT1" general control ball valve 10, quick-fit joint 11, air release valve 12, internal sewage pipe 13, external sewage device 14, empty pipe fixing rubber 15, dust cap 16, operation Warehouse roof 17, gas cylinder 18, frame 19, coiled pipe 20. After the present invention is implemented, the end plug is used as a reference for installation, and the sequence of connection equipment is as follows:

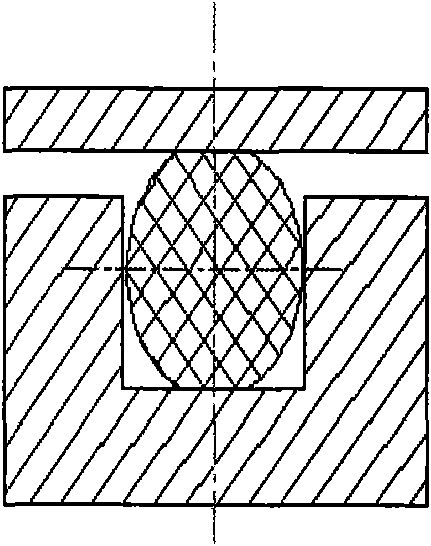

[0042] According to the structure of the rear end plug 1, the O-ring 2 and the K-type retaining ring 3 are combined and assembled to the rear end plug;

[0043] Connect one section of the safety device 4 with NPT1.5” thread to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com