Extrusion deformation process of high-strength magnesium alloy thick plate

A technology for extrusion deformation and magnesium alloys, which is applied in the field of extrusion deformation involving magnesium alloys, and can solve the problems of lack of large-scale high-performance magnesium alloy sheets, low symmetry, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, a magnesium alloy semi-continuous casting billet (specification: Φ210mm, length greater than 5000mm) is used. After extrusion, the specifications of the plate are: width 150mm, thickness 20mm, length 3000mm, and the inner diameter of the extrusion cylinder is 205mm.

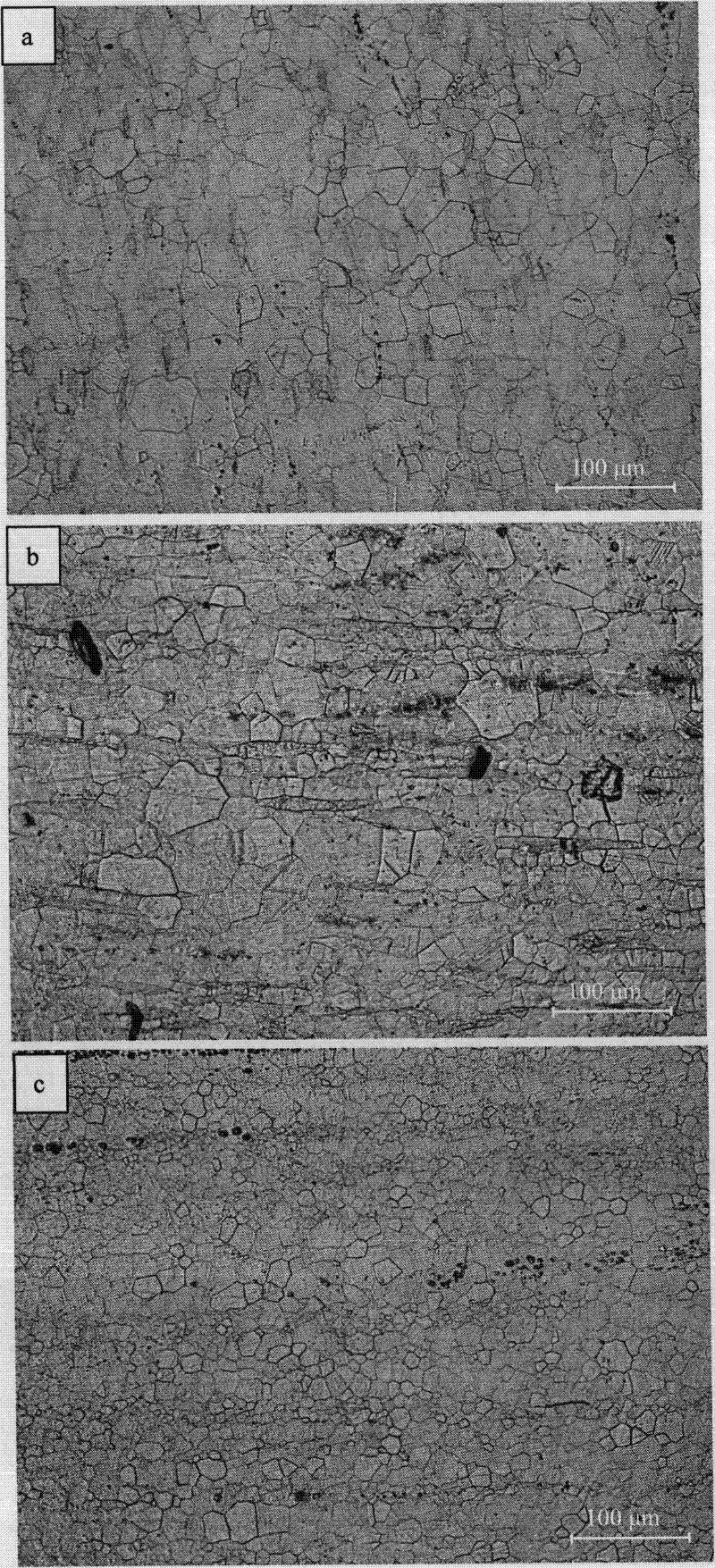

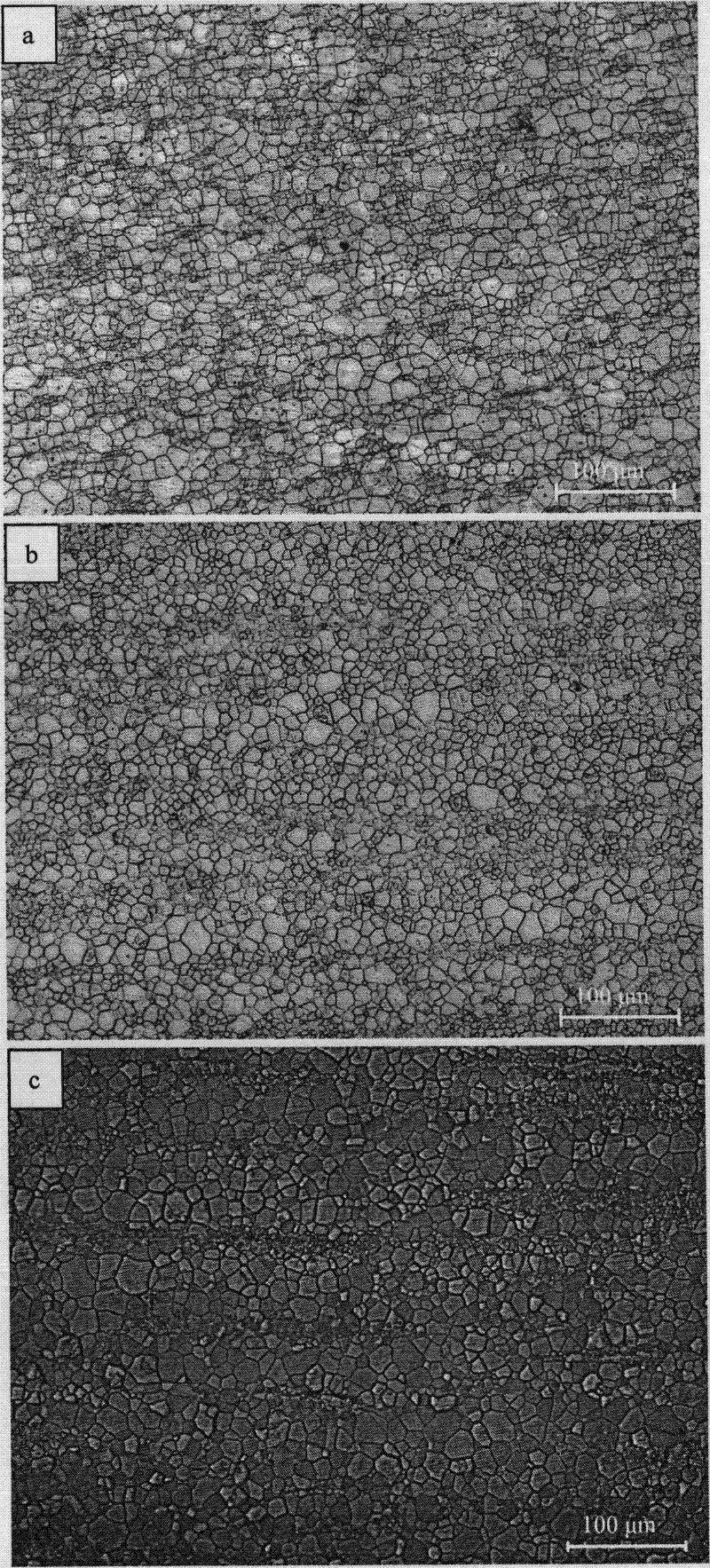

[0020] First, homogenize the magnesium alloy billet at 455°C / 5h+545°C / 15h, quickly cool it and peel it off; then heat the extrusion die and extrusion barrel at a temperature of 450°C, and then heat the magnesium alloy billet to 460°C After being kept at ℃ for 2 hours, put it into the extrusion cylinder, and extrude it on a 3600-ton horizontal hydraulic press with an extrusion ratio of 11; the optical microstructure of the extruded alloy is as follows: figure 1 It can be seen from the optical microstructure of the extrusion longitudinal section that complete dynamic recrystallization occurred during the extrusion process, and the grain size is about 13.5 μm; the macroscopic picture of the...

Embodiment 2

[0022] In this embodiment, a magnesium alloy semi-continuous casting billet (specification: Φ210mm, length greater than 5000mm) is used. After extrusion, the specifications of the plate are: width 150mm, thickness 20mm, length 3000mm, and the inner diameter of the extrusion cylinder is 205mm.

[0023] First, homogenize the magnesium alloy billet at 455°C / 5h+545°C / 15h, quickly cool it and peel it; then heat the extrusion die and extrusion barrel at a temperature of 400°C, and then heat the magnesium alloy billet to 390 After being kept at ℃ for 2 hours, put it into the extrusion cylinder, and extrude it on a 3600-ton horizontal hydraulic press with an extrusion ratio of 11; the optical microstructure of the extruded alloy is as follows: figure 1 As shown, it can be seen from the optical microstructure of the extrusion longitudinal section that complete dynamic recrystallization has occurred during the extrusion process, and the grains are fine, and the grain size is about 8 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com