Process for treating solid waste compost in hoggery

A solid waste and treatment process technology, which is applied in the treatment of biological organic parts, organic fertilizers, fertilization devices, etc., can solve problems such as affecting the normal growth of livestock and poultry, polluting the surrounding air, affecting soil quality, etc. Low soil damage and high composting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

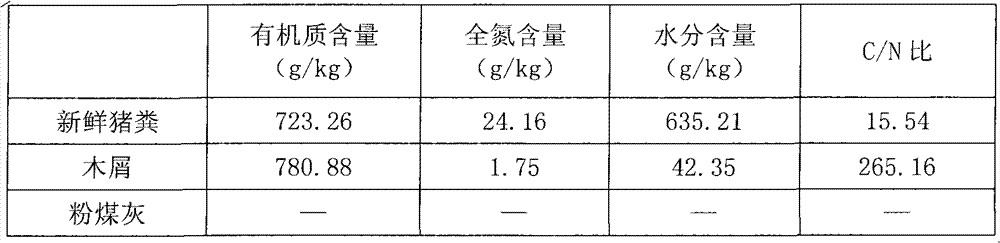

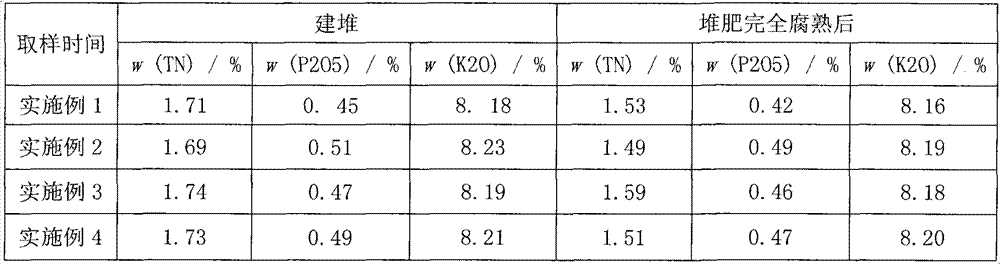

[0035] a. fresh pig manure, fly ash accounting for 1% of the weight of fresh pig manure, particle size of 100-180 mesh wood chips and water are mixed and stirred evenly to make the water mass fraction 71%, the C / N ratio is 25, and the pH is 7.5 stacking, pH adjustment is realized by adding diluted acid solution (such as hydrochloric acid) or alkali solution (such as sodium hydroxide solution);

[0036] b. Divide the stacked material into a bottom area of 3×5m 2 , the volume is 10-15m 3 The piles were piled up and left to rot until they were fully decomposed to obtain compost. During the period of heating up and high-temperature fermentation of the pile, the pile was turned every 5 days, and during the period of cooling and post-ripening of the pile, the pile was turned every 8 days, and the compost was weighed and analyzed.

[0037] Among them, a thermometer was used to measure and record the compost temperature at noon every day. It can be seen that the temperature of the ...

Embodiment 2

[0039]a. Fresh pig manure, fly ash accounting for 1.5% of the fresh pig manure weight, particle size is 100-180 mesh wood chips and water are mixed and stirred evenly to make the water mass fraction 75%, C / N ratio is 30, pH is 8.0 stacking, pH adjustment is realized by adding diluted acid solution (such as hydrochloric acid) or alkali solution (such as sodium hydroxide solution);

[0040] b. Divide the stacked material into a bottom area of 4×5m 2 , the volume is 16-20m 3 The stacks are stacked and stacked statically. The bottom of each stack is horizontally arranged with an air intake pipe. The distance between two adjacent air intake pipes is 20cm. One end of the air intake pipe is open along its longitudinal direction, and the other end is closed. Holes, two adjacent radial air inlet holes are separated by 10-12cm, and each inlet pipe of the AOC-008 blower is 0.20m 3 The ventilation volume per minute is used for intermittent air intake. The intermittent air intake metho...

Embodiment 3

[0043] a. fresh pig manure, fly ash accounting for 1.3% of the weight of fresh pig manure, particle size of 100-180 mesh wood chips and water are mixed and stirred evenly to make the water mass fraction 73%, the C / N ratio is 28, and the pH is 8.0 stacking, pH adjustment is realized by adding diluted acid solution (such as hydrochloric acid) or alkali solution (such as sodium hydroxide solution);

[0044] b. Divide the stacked material into a bottom area of 3.5×5m 2 , the volume is 16-20m 3 The stacks are stacked and stacked statically. The bottom of each stack is horizontally arranged with an air intake pipe. The distance between two adjacent air intake pipes is 25cm. One end of the air intake pipe is open along its longitudinal direction, and the other end is closed. Holes, two adjacent radial air inlet holes are separated by 10-12cm, and each inlet pipe of the AOC-008 blower is 0.20m 3 The ventilation volume per minute is used for intermittent air intake. The intermitten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com