Preparation method of cadmium telluride quantum dot

A cadmium telluride quantum dot and quantum dot technology, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of uneven particle size and wide emission peak, and achieve low price, mild reaction conditions, and good water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

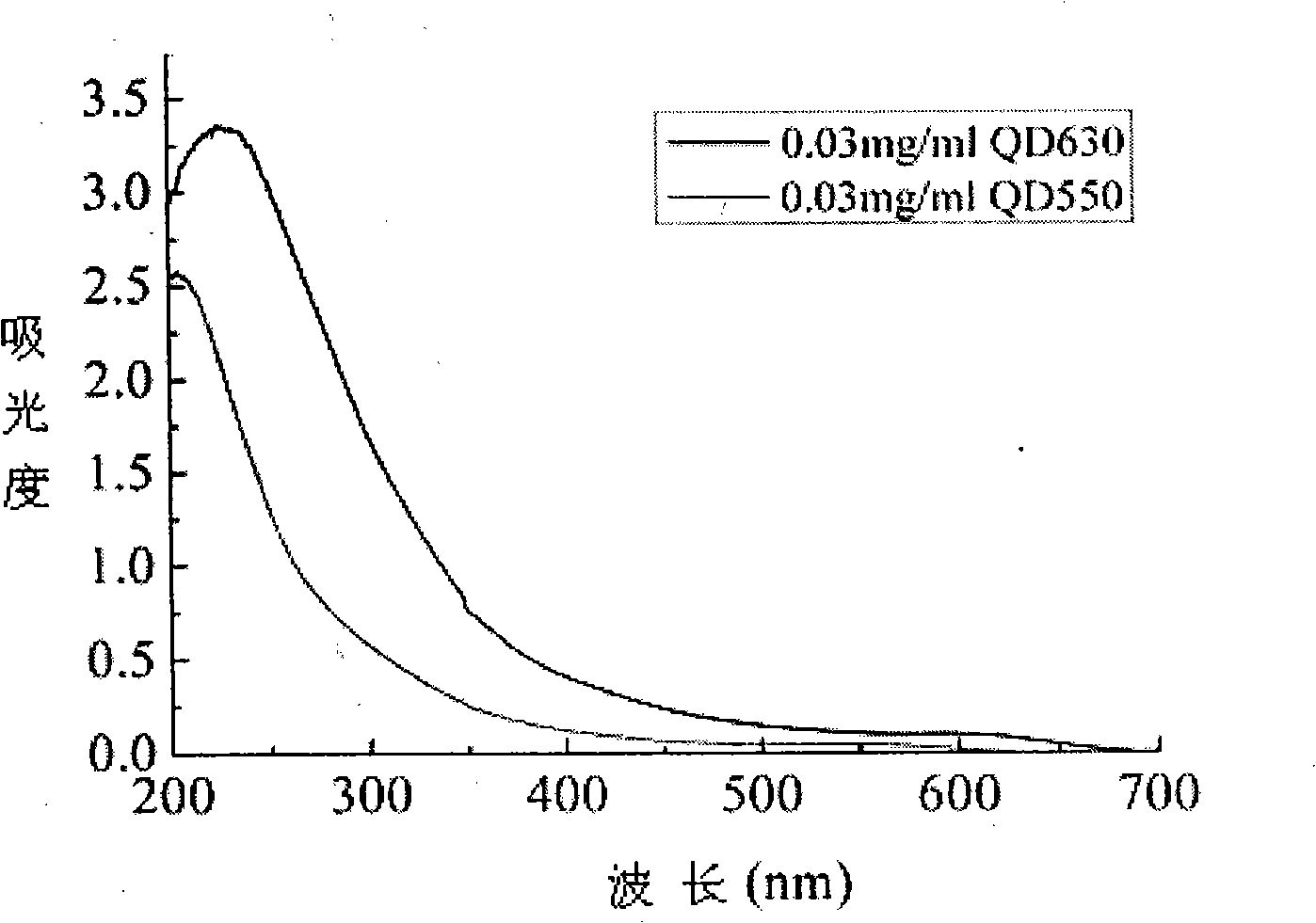

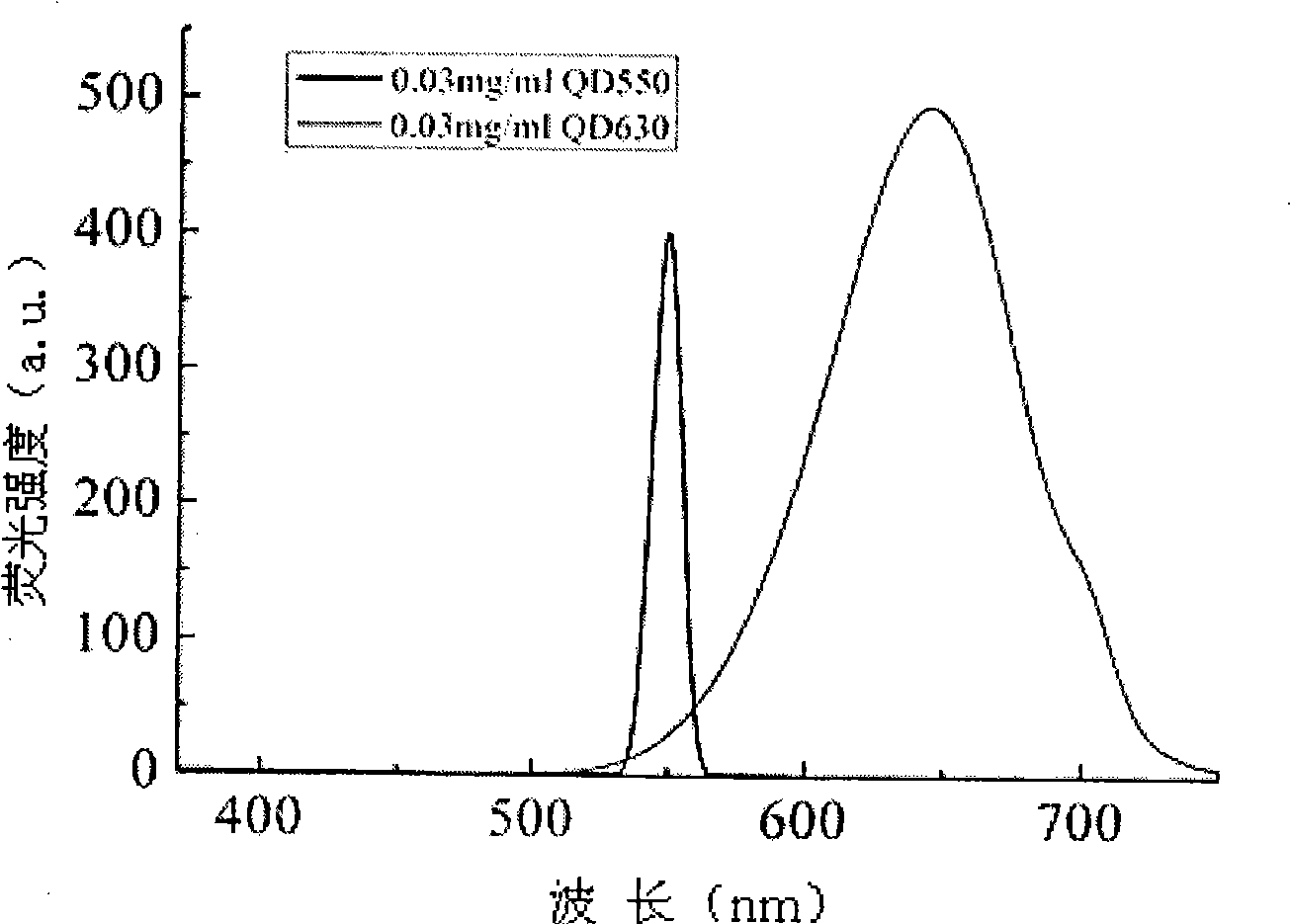

Image

Examples

Embodiment 1

[0025] A kind of preparation method of cadmium telluride quantum dot, will 0.8gNaBH 4 Add 0.16g tellurium powder into a 50mL Erlenmeyer flask, add 10mL deionized water, ventilate with nitrogen for 20min, immediately tighten the soft rubber stopper, insert a syringe needle, and stir magnetically for 2h to obtain milky white freshly prepared NaHTe solution. Take 0.5mL 200mmol / LCdCl 2 Stock solution, 0.5mL 200mmol / L freshly prepared mercaptopropionic acid solution, the molar ratio of the two is 1:1, add in another 50mL conical flask, add 14mL deionized water, then dropwise add 1mol / L NaOH solution, Adjust the pH to 12.0, blow nitrogen into the Cd precursor solution for 20 minutes, immediately tighten the soft rubber stopper, and insert a syringe needle; draw 0.2 mL of freshly prepared NaHTe solution with a 1 mL syringe, and quickly add it to the Erlenmeyer flask containing the Cd precursor solution At this time, the molar ratio of Cd to NaHTe is 1:0.167, put the Erlenmeyer flask...

Embodiment 2

[0027] A kind of preparation method of cadmium telluride quantum dot, will 0.8gNaBH 4 Add 0.16g tellurium powder into a 50mL Erlenmeyer flask, add 10mL deionized water, ventilate with nitrogen for 20min, immediately tighten the soft rubber stopper, insert a syringe needle, and stir magnetically for 2h to obtain milky white freshly prepared NaHTe solution. Take 0.5mL of 200mmol / L CdCl 2Stock solution, 1.0mL 200mmol / L freshly prepared mercaptopropionic acid solution, the molar ratio of the two is 1:2, add in another 50mL Erlenmeyer flask, add 14mL deionized water, then dropwise add 1mol / L NaOH solution, Adjust the pH to 12.0, blow nitrogen into the Cd precursor solution for 20 minutes, immediately tighten the soft rubber stopper, and insert a syringe needle; draw 0.2 mL of freshly prepared NaHTe solution with a 1 mL syringe, and quickly add it to the Erlenmeyer flask containing the Cd precursor solution At this time, the molar ratio of Cd to NaHTe was 1:0.167. Put the Erlenmeye...

Embodiment 3

[0029] A kind of preparation method of cadmium telluride quantum dot, will 0.8gNaBH 4 Add 0.16g tellurium powder into a 50mL Erlenmeyer flask, add 10mL deionized water, ventilate with nitrogen for 20min, immediately tighten the soft rubber stopper, insert a syringe needle, and stir magnetically for 2h to obtain milky white freshly prepared NaHTe solution. Take 0.5mL of 200mmol / L CdCl 2 Stock solution, 0.5mL 200mmol / L cysteamine solution freshly prepared, the molar ratio of the two is 1:1, put into another 50mL Erlenmeyer flask, add 14mL deionized water, then dropwise add 1mol / L NaOH solution, Adjust the pH to 6.5, blow nitrogen into the Cd precursor solution for 20 minutes, immediately tighten the soft rubber stopper, and insert a syringe needle; draw 0.2mL of freshly prepared NaHTe solution with a 1mL syringe, and quickly add it to the Erlenmeyer flask containing the Cd precursor solution At this time, the molar ratio of Cd to NaHTe is 1:0.167, put the Erlenmeyer flask into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com