Method for preparing nanosilver/nano silicon dioxide-containing antibacterial biological dressing

A technology of nano-silica and biological dressings, applied in the field of preparation of biomedical materials, can solve the problems of high efficiency, large particle size, and wide size distribution that affect antibacterial performance, and achieve the promotion of wound healing, dense and uniform voids, and high porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

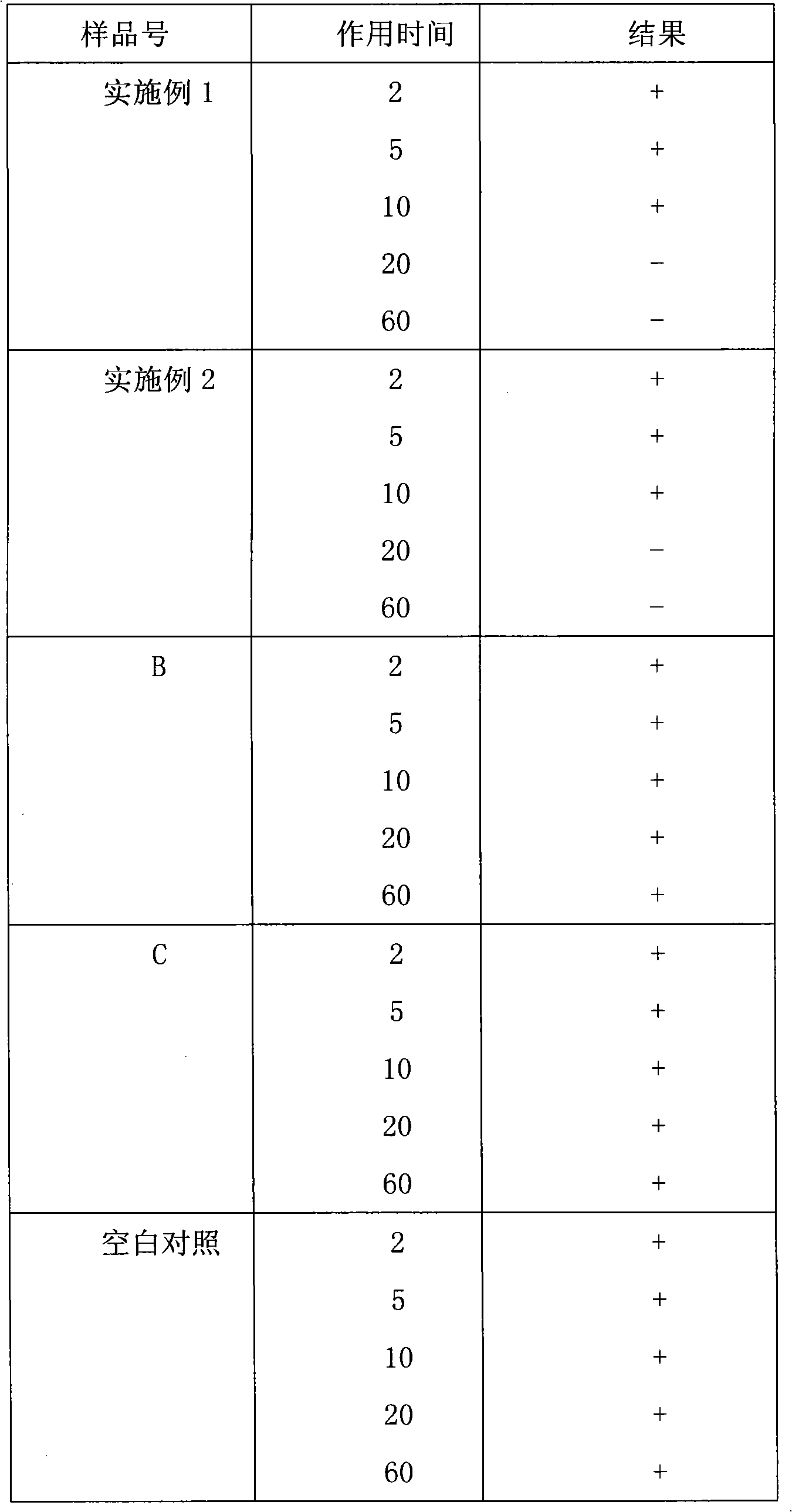

Embodiment 1

[0025] In 200 mL of absolute ethanol, add 1.0 g of silicon dioxide dried at 120° C., and stir evenly. 1.0 mL of water and 0.054 g of sodium hydroxide were added, and the mixture was stirred for 24 hours in a constant temperature water bath at 25°C. 20 mL of 7.6 g / L silver nitrate ethanol solution was added dropwise at a constant speed for 30 min, and after 10 min of reaction, centrifuged, washed with ethanol, and dried to obtain silver-loaded silica powder.

[0026] 0.05 g of chitosan was dissolved in a 5% by volume dilute acetic acid aqueous solution to prepare a 1.0% by mass chitosan solution. 0.05 g of polyvinyl alcohol was dissolved in boiling water to prepare a polyvinyl alcohol solution with a mass fraction of 1.0%. The above chitosan solution and polyvinyl alcohol solution are mixed in a volume ratio of 1:1 and then fully stirred to obtain a polyvinyl alcohol / chitosan blended solution. Weigh 20g of polyvinyl alcohol, dissolve it in 200mL of boiling water, cool to 50°C...

Embodiment 2

[0030] In 280 mL of anhydrous ethanol, add 0.5 g of silica dried at 120° C., and stir evenly. 2.0 mL of water and 0.054 g of sodium hydroxide were added, and the mixture was stirred for 24 hours in a constant temperature water bath environment at 25°C. 30 mL of 7.6 g / L ethanol solution of silver nitrate was added dropwise at a uniform speed for 40 min, and after 10 min of reaction, centrifuged, washed with ethanol, and dried to obtain silver-loaded silica powder.

[0031]0.05 g of chitosan was dissolved in a dilute acetic acid aqueous solution with a volume fraction of 5% to prepare a chitosan solution with a mass fraction of 1.0%. Dissolve 0.05 g of polyvinyl alcohol in 5 ml of boiling water to prepare a polyvinyl alcohol solution with a mass fraction of 1.0%. The above chitosan solution and polyvinyl alcohol solution are mixed in a volume ratio of 1:1 and then fully stirred to obtain a polyvinyl alcohol / chitosan blended solution. Weigh 20g of polyvinyl alcohol, dissolve it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com