Three-layer electrostatic spinning ordered fiber nerve conduit and preparation and application thereof

A technique for electrospinning and nerve conduit, which is applied in the field of nerve conduit and its preparation and application, can solve the problem of unpublished yarn fineness, etc., and achieve the effects of promoting growth and migration, high economic benefits, and promoting value-added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Dissolving the PHBV in a volume ratio=4:1 chloroform / acetone solution and stirring evenly to obtain a PHBV / chloroform / acetone solution with a mass percent of PHBV of 7%;

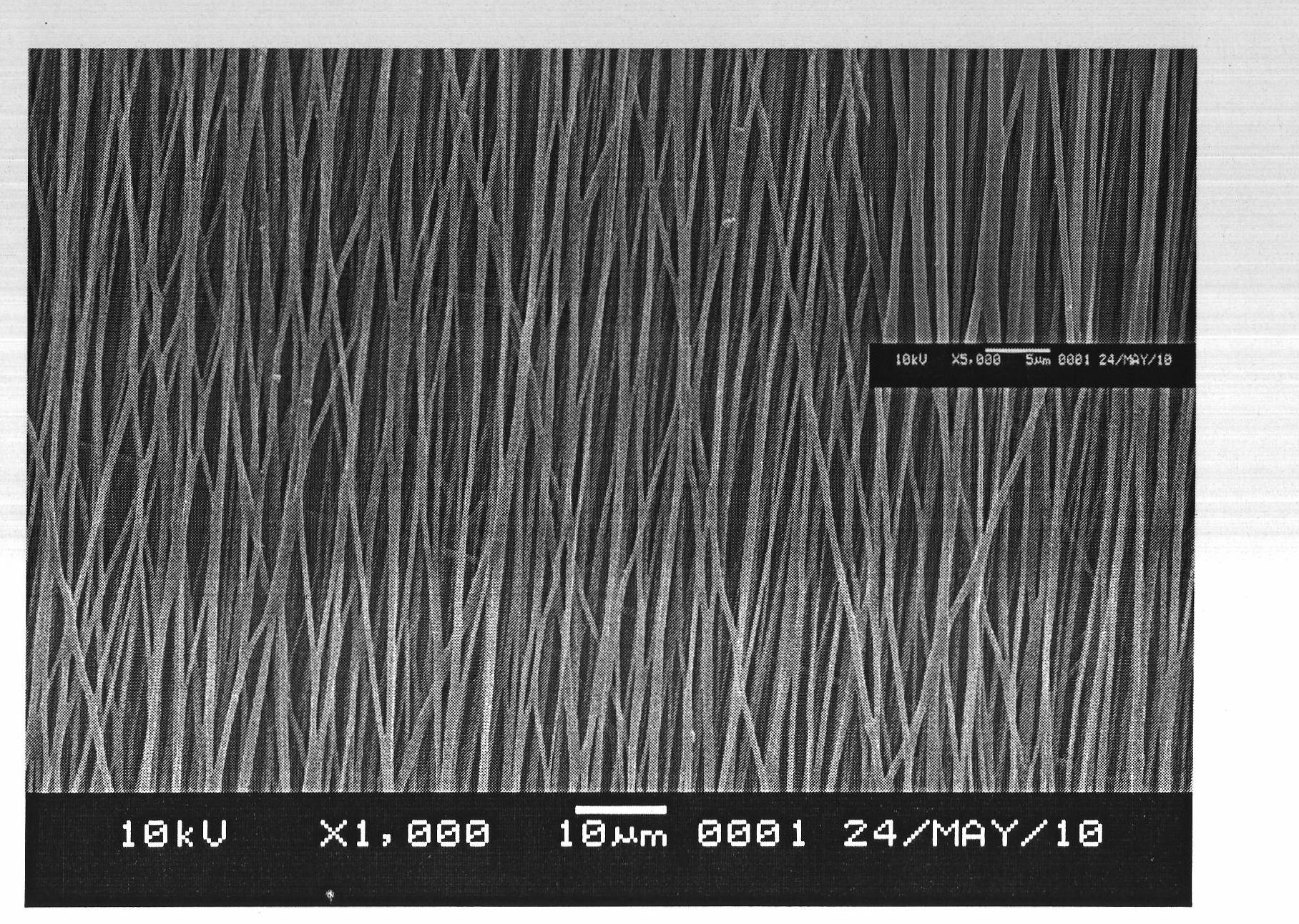

[0038] (2) Carry out electrospinning of PHBV / chloroform / acetone solution, the solution propulsion speed is 1.5mL / h, the applied voltage value is 7kv, the receiving distance is 15cm, and it is received by high-speed winding drum to obtain a fiber film with good orientation ;

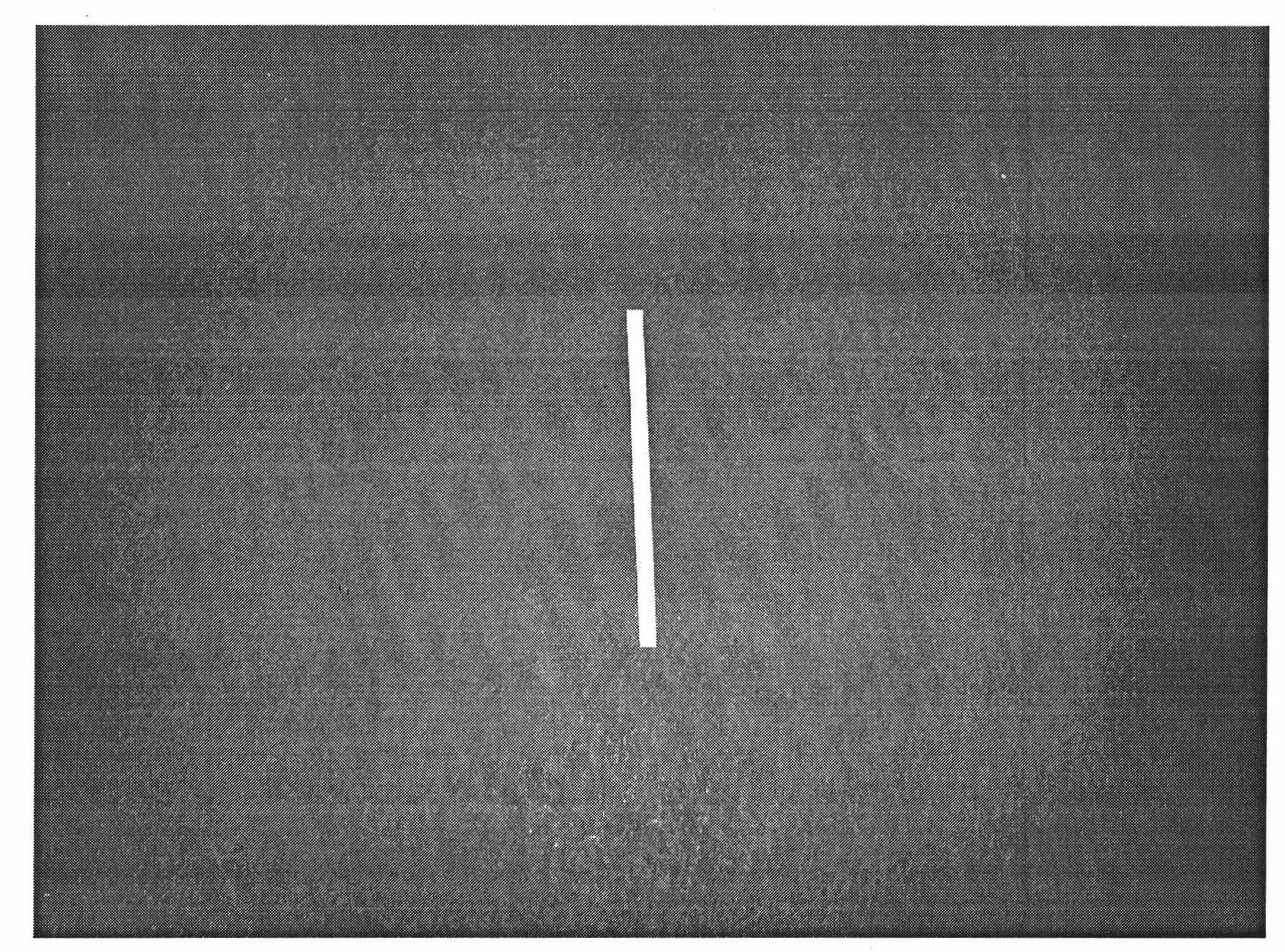

[0039] (3) After the electrospinning is finished, remove an ordered fiber film from the winding drum, and wind it on a mandrel to form an inner tube with fibers arranged in the axial direction, and the diameter of the mandrel is about 2mm;

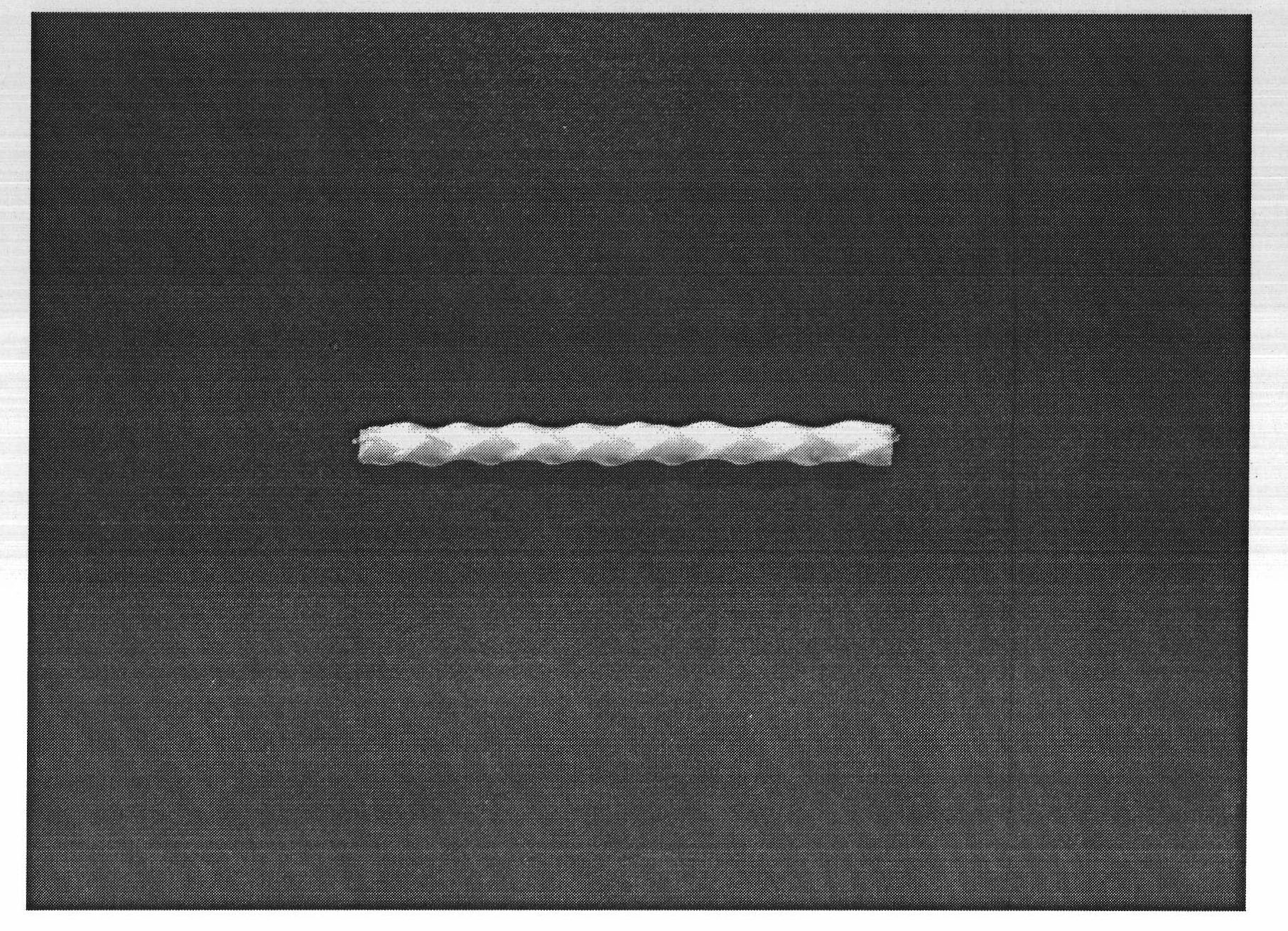

[0040] (4) Weave polyglycolic acid (PGA) fibers into a 3mm mesh circular tube, put it on the inner tube, and stretch it slightly to fix it;

[0041] (5) Fix the mandrel covered with the inner tube and the intermediate tube on the high-speed winding collection device, and carry out the el...

Embodiment 2

[0044] (1) Dissolving PHBV in a volume ratio=7:1 chloroform / acetone solution, stirring evenly to obtain a PHBV / chloroform / acetone solution with a mass percent of PHBV of 6%;

[0045] (2) Carry out electrospinning of PHBV / chloroform / acetone solution, the solution propulsion speed is 1mL / h, the applied voltage value is 10kv, the receiving distance is 13cm, and the high-speed winding drum is used to receive, and a fiber film with good orientation is obtained;

[0046] (3) After the electrospinning is finished, remove an ordered fiber film from the winding drum and wind it on a mandrel to form an inner tube in which the fibers are arranged in the axial direction, and the diameter of the mandrel is about 1mm;

[0047] (4) Weave polycaprolactone (PCL) fibers into a 2mm mesh circular tube, put it on the inner tube, and stretch it slightly to fix it;

[0048] (5) Fix the mandrel covered with the inner tube and the intermediate tube on the high-speed winding collection device, and carr...

Embodiment 3

[0051] (1) Dissolving PHBV in a volume ratio=5:1 chloroform / acetone solution, stirring evenly to obtain a PHBV / chloroform / acetone solution with a mass percentage of PHBV of 5%;

[0052] (2) Carry out electrospinning of PHBV / chloroform / acetone solution, the solution propulsion speed is 0.5mL / h, the applied voltage value is 15kv, the receiving distance is 17cm, and it is received by high-speed winding drum to obtain a fiber film with good orientation ;

[0053] (3) After the electrospinning is finished, remove an ordered fiber film from the winding drum, and wind it on a mandrel to form an inner tube with fibers arranged in the axial direction, and the diameter of the mandrel is about 2.5mm;

[0054] (4) Weave polyglycolide lactide (PGLA) fibers into a 3mm mesh circular tube, put it on the inner tube, and stretch it slightly to fix it;

[0055] (5) Fix the mandrel covered with the inner tube and the intermediate tube on the high-speed winding collection device, and perform elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com