Preparation method of metal meshed board and cover plate and electronic device

A metal mesh plate, metal plate technology, applied in metal processing equipment, metal casings, electrical components and other directions, can solve problems such as cost increase, affecting product yield, expanding surface area, etc., to achieve the effect of solving the problem of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

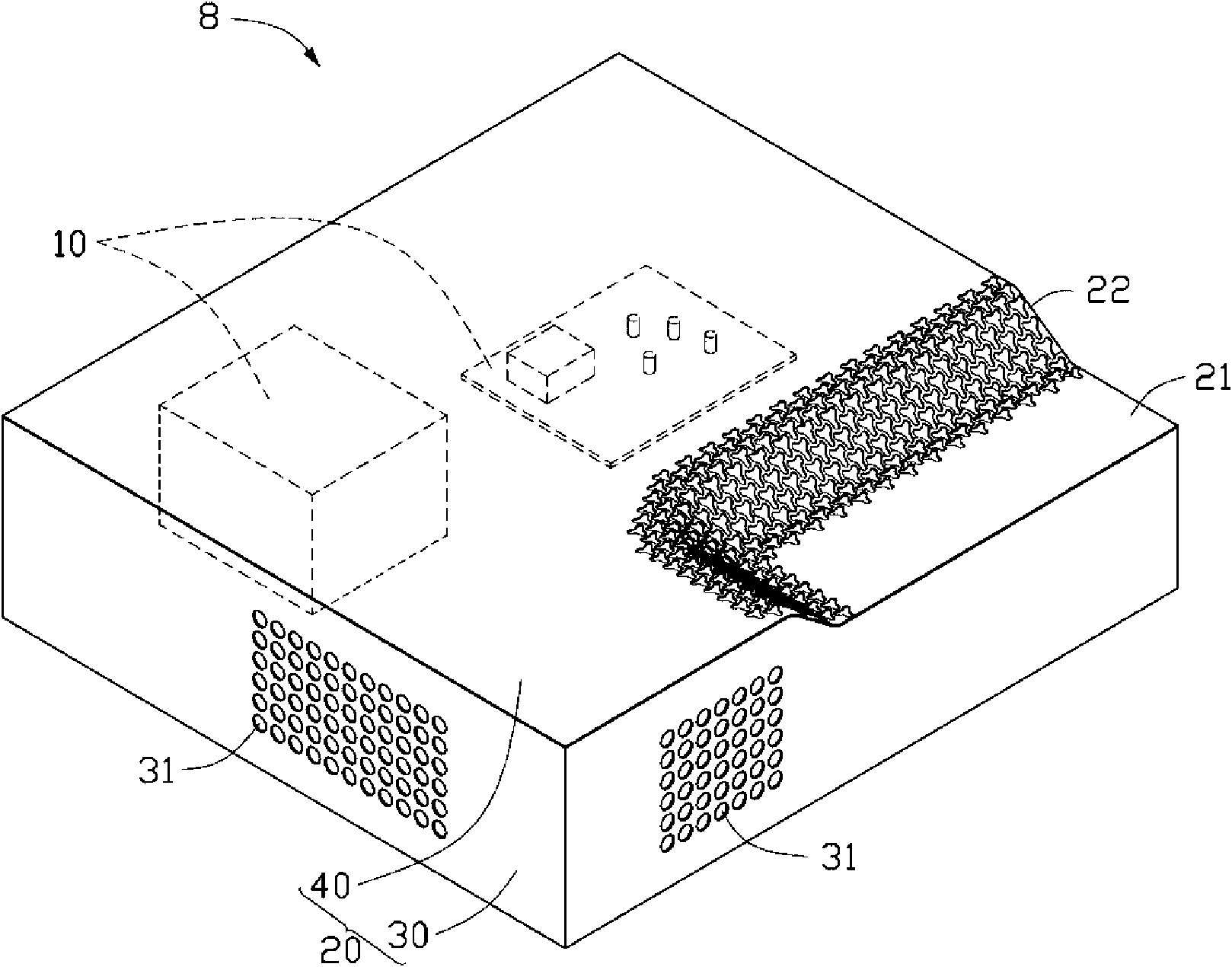

[0018] see figure 1 A preferred embodiment of the electronic device 8 of the present invention includes a metal casing 20 and a plurality of electronic components 10 accommodated in the metal casing 20 .

[0019] In this embodiment, the maximum frequency of the electromagnetic waves generated by the electronic component 10 during operation does not exceed 2 GHz, that is, the minimum wavelength of the generated electromagnetic waves is not less than 150 mm.

[0020] The casing 20 includes a frame 30 and a cover 40 covering the frame 30 .

[0021] Several holes 31 are provided on the frame 30 . The diameter of each hole 31 is not greater than one-thirtieth of the minimum wavelength, that is, 5 mm, so as to prevent electromagnetic waves generated by the electronic components 10 from leaking out of the casing 20 . The hole 31 can assist the electronic device 8 to dissipate heat.

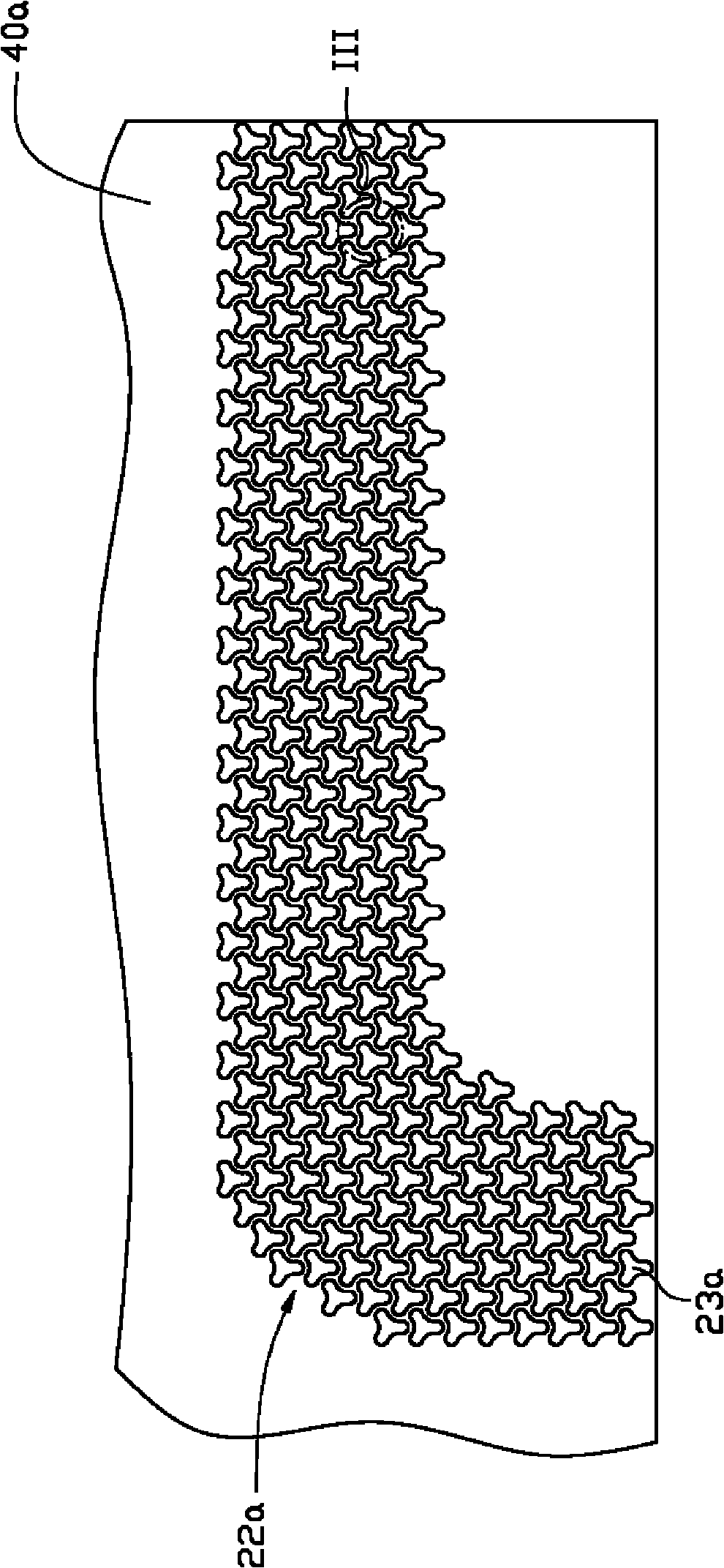

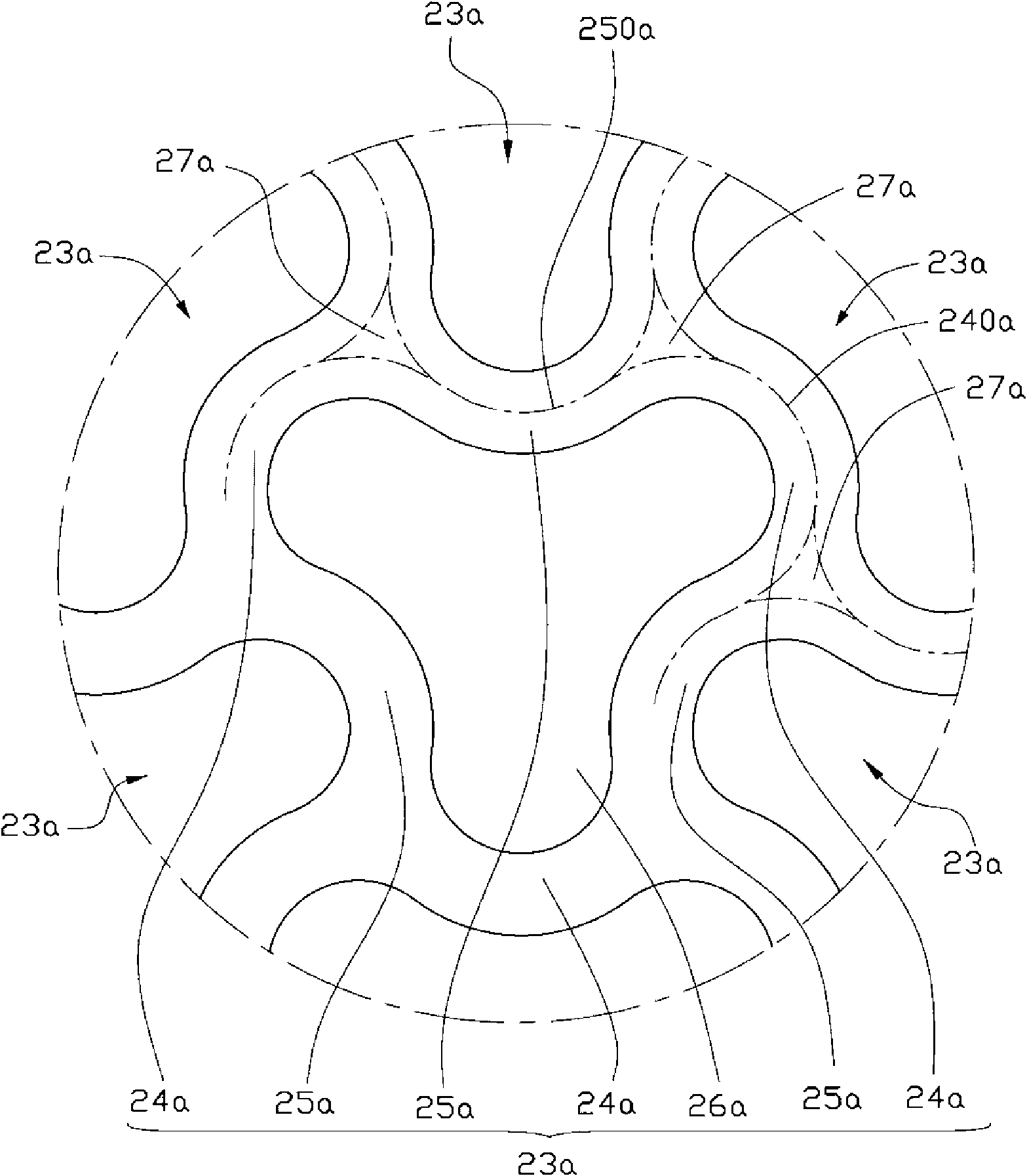

[0022] The cover plate 40 can be made of iron, and the iron cover plate can be processed by second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com