Finned tube type heat exchanger and manufacture method thereof

A fin-and-tube heat exchanger technology, which is applied to the fin-tube heat exchanger and its manufacturing field, can solve the problem of different heat transfer performance and pressure loss, inability to give full play to the performance of the heat exchanger, and the heat exchange of the heat exchanger. Uneven capacity and other problems, to achieve the effect of reducing useless residual materials, reducing noise, and promoting the flow of condensate water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

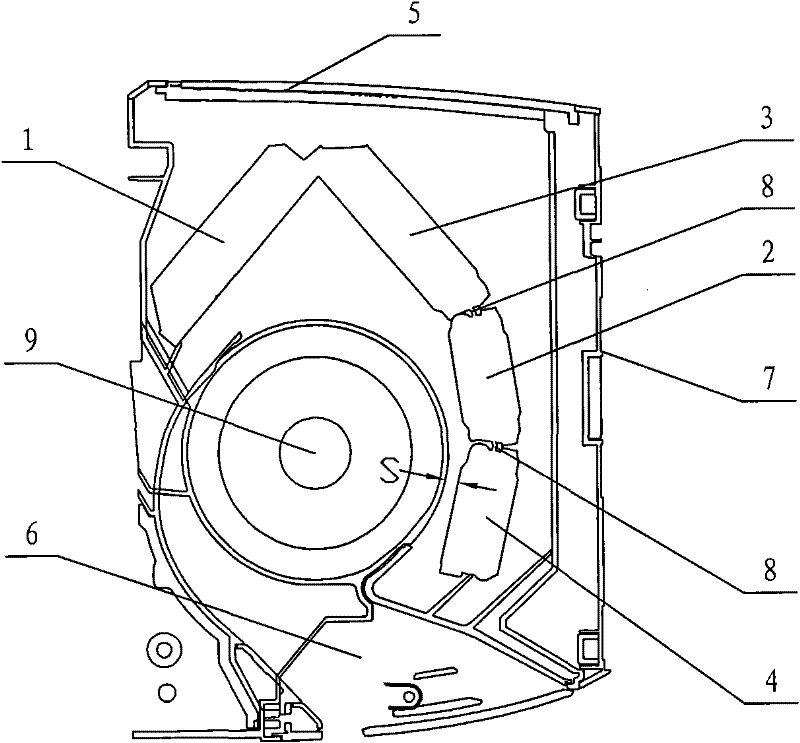

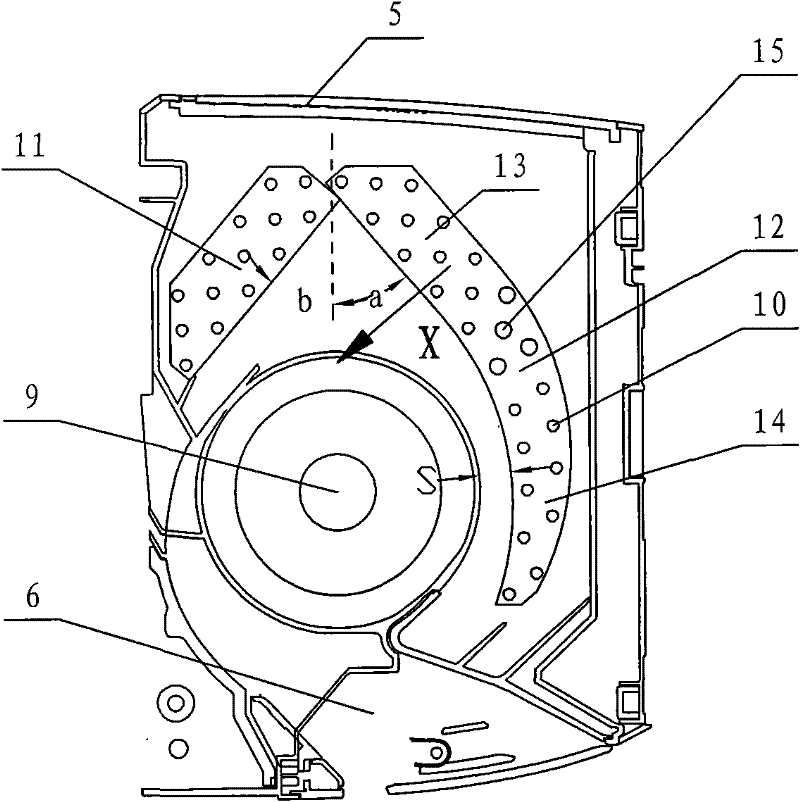

[0044] see Figure 3-Figure 4 , the second heat exchanger fin 12 of this finned tube heat exchanger is a curved whole, formed by folding the second heat exchanger fin 12 and the first heat exchanger fin 11 as image 3 In the shown heat exchanger, the first heat exchanger fin 11 and the second heat exchanger fin 12 are folded into an inverted V shape above the cross-flow fan 9, and the second heat exchanger fin 12 is approximately C-shaped. ; Then, assemble the heat exchanger in the frame of the indoor heat exchanger to form as figure 2 Air conditioner indoor unit shown.

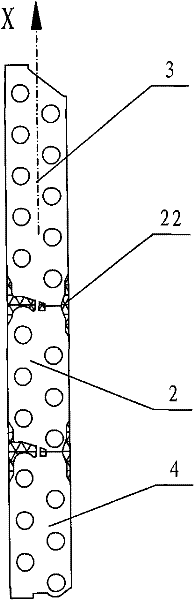

[0045] The upper fins 13 of the second heat exchanger fins and the edges of the first heat exchanger fins 11 are parallel straight lines. The edge of the lower fin 14 in the second heat exchanger fin is arc-shaped. In the average airflow direction, that is, along the X direction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com