Safety and explosion prevention tire rim structure

A technology of rims and tires, applied in rims, tire parts, transportation and packaging, etc., can solve the problems of vehicle loss of balance and control, catastrophic accidents, vehicle loss of control, etc., and achieve impact relief, low cost, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

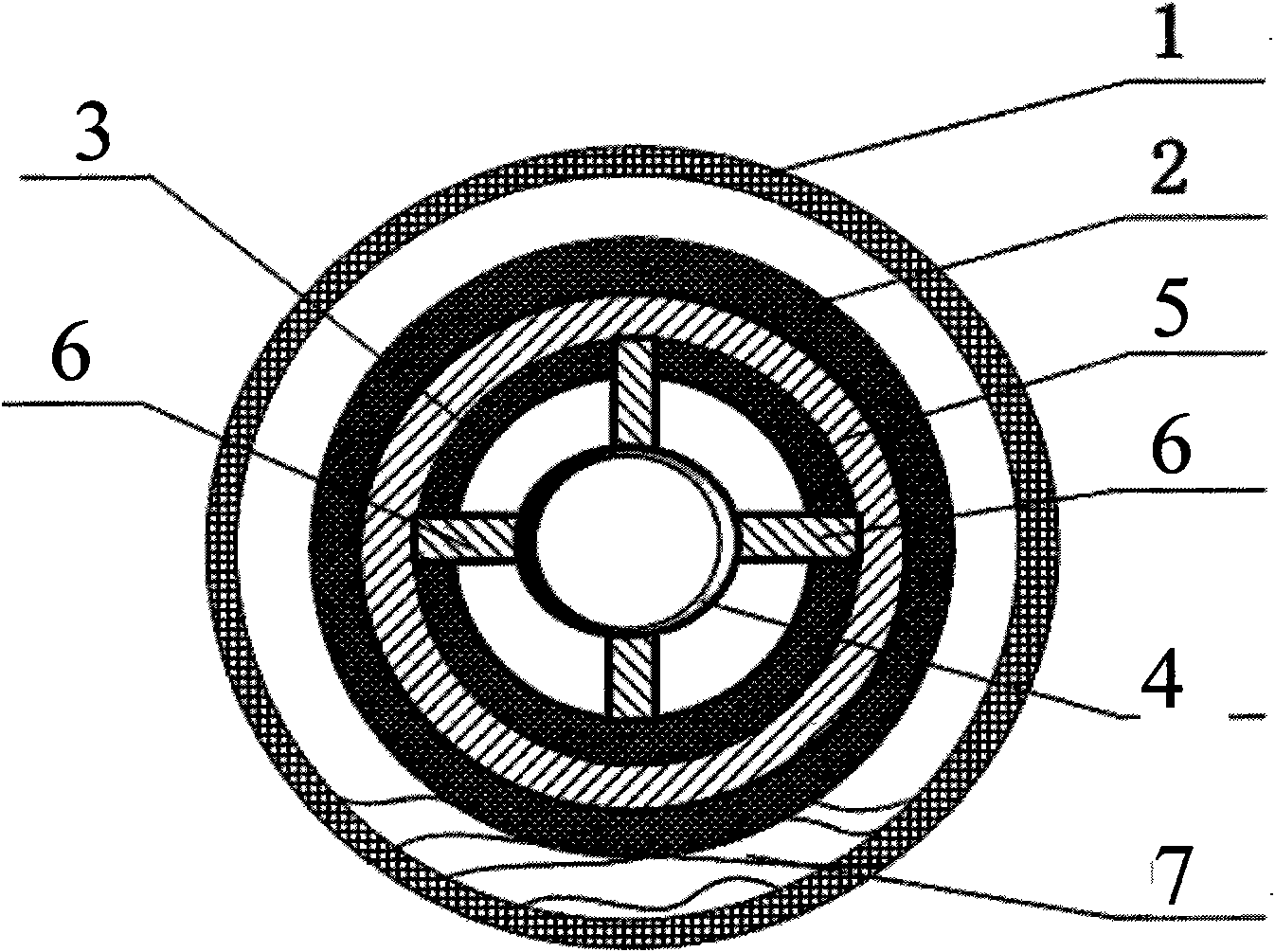

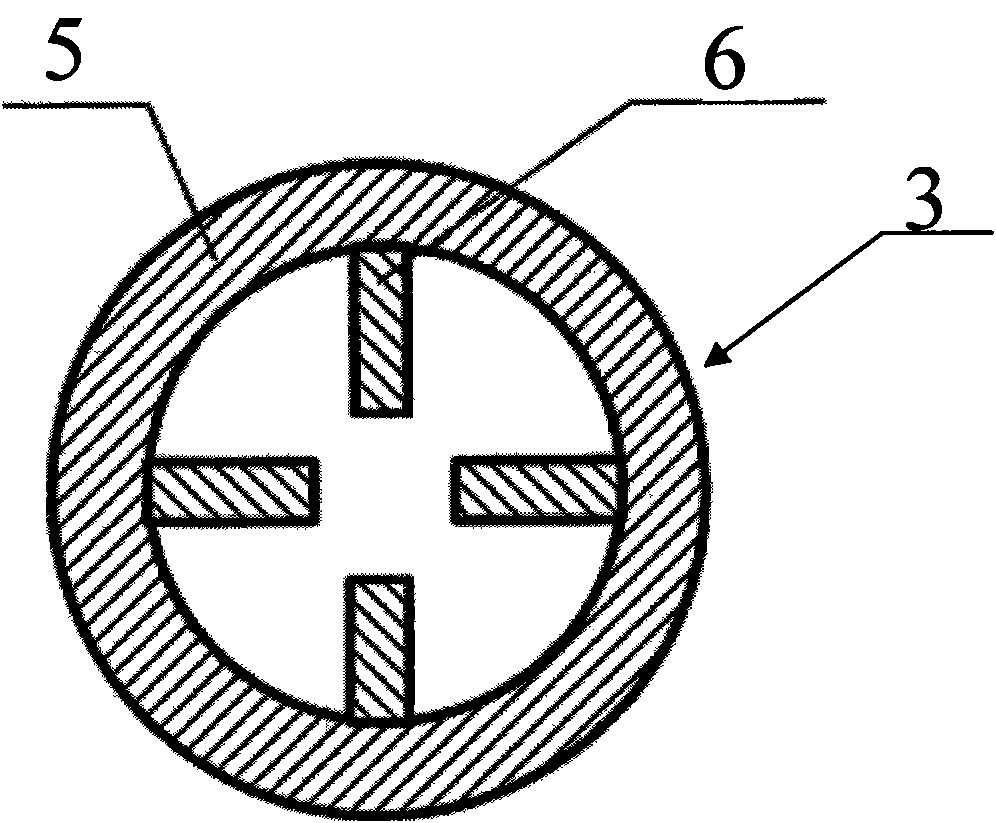

[0016] A safety explosion-proof tire rim structure includes a tire casing 1, a supporting tire 2, a supporting frame 3 and a rim 4, and the supporting frame 3 includes a circular ring 5 and four struts 6. The supporting frame 3 is welded with four poles 6 . Its characteristics are:

[0017] There is tire repair liquid 7 between cover tire 1 and supporting tire 2. The main ingredients of tire repair fluid 7 are poly-p-phenylene terephthalamide and sodium carboxymethyl cellulose.

[0018] The support tire 2 wraps the ring 5 part of the support frame 3 completely. Support tire 2 is elastomers such as rubber, polyurethane rigid foam plastics.

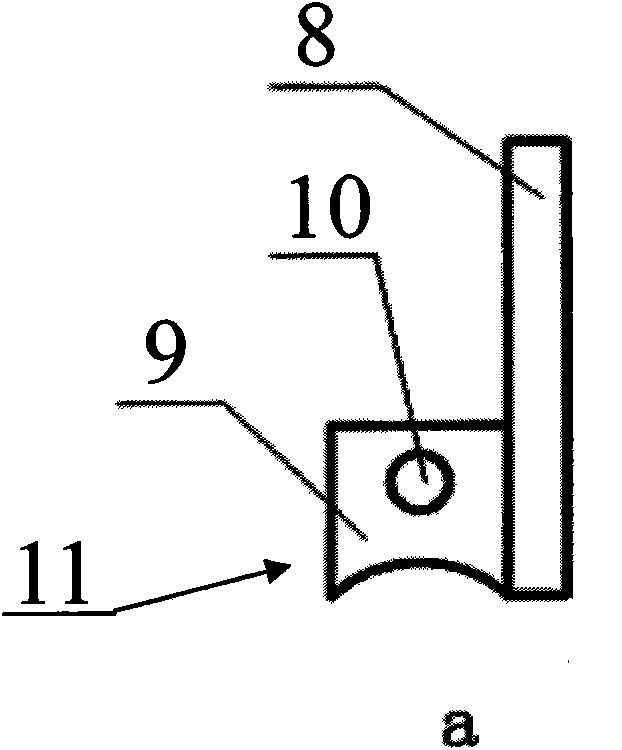

[0019] The rim 4 is welded with a connection part 11 connected with the support frame, and the connection part 11 is shown in image 3 , it includes a block 8, a connecting steel plate 9, a bolt hole 10, and the strut 6 of the support frame 3 can be connected with the rim 4 by using fastening bolts.

[0020] The rim 4 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com