Porous ceramic negative pressure slip casting device and method for preparing ceramic blank

A technology of grouting molding and green body, which is applied in the field of molding process, preparation of slurry, and porous ceramic negative pressure grouting molding device, which can solve the problem of affecting the optical and laser properties of transparent ceramics, uneven density at the center and edge of the green body, It takes a long time for molding and drying to achieve the effect of easy realization of high-density green body, convenient operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

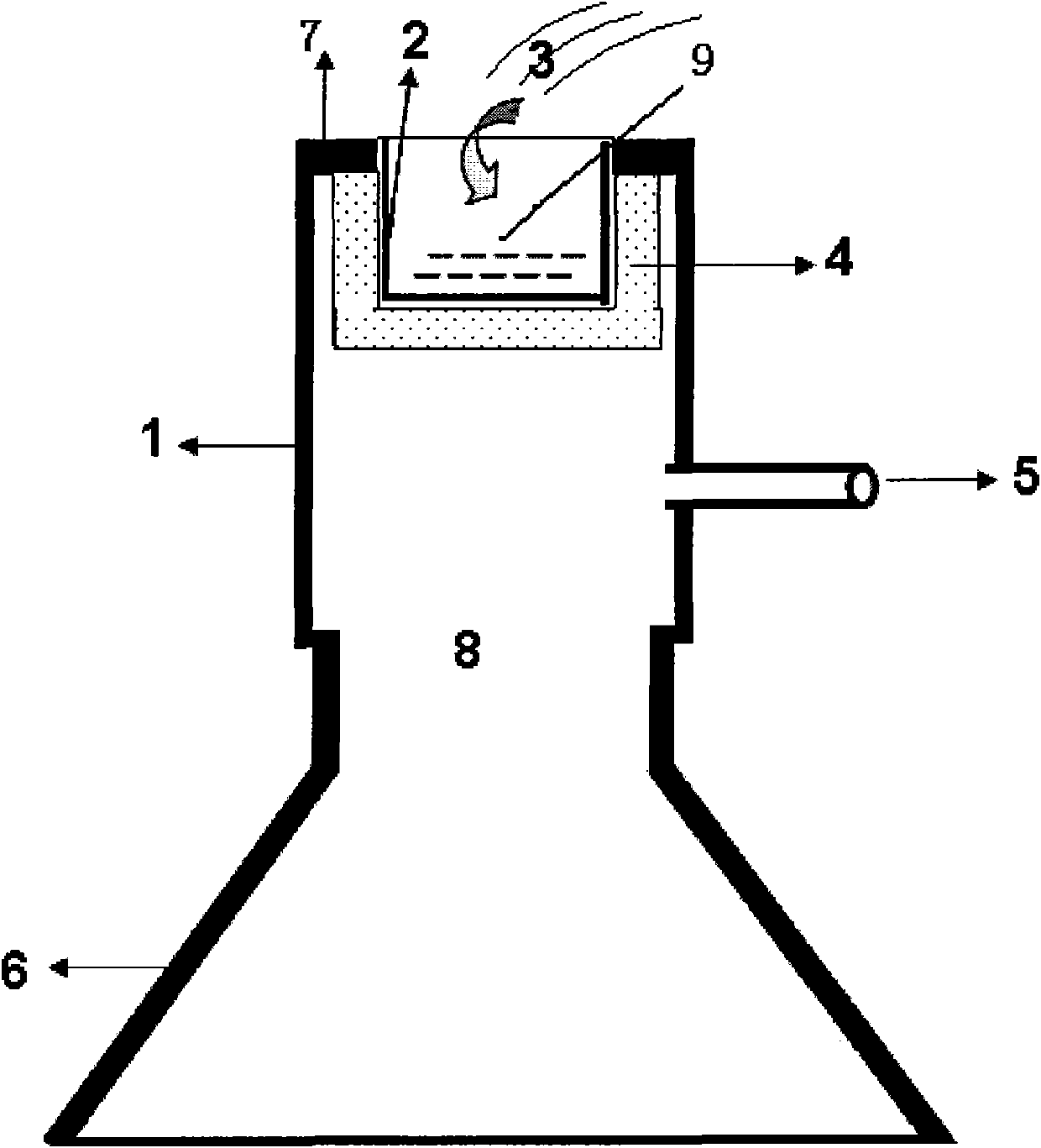

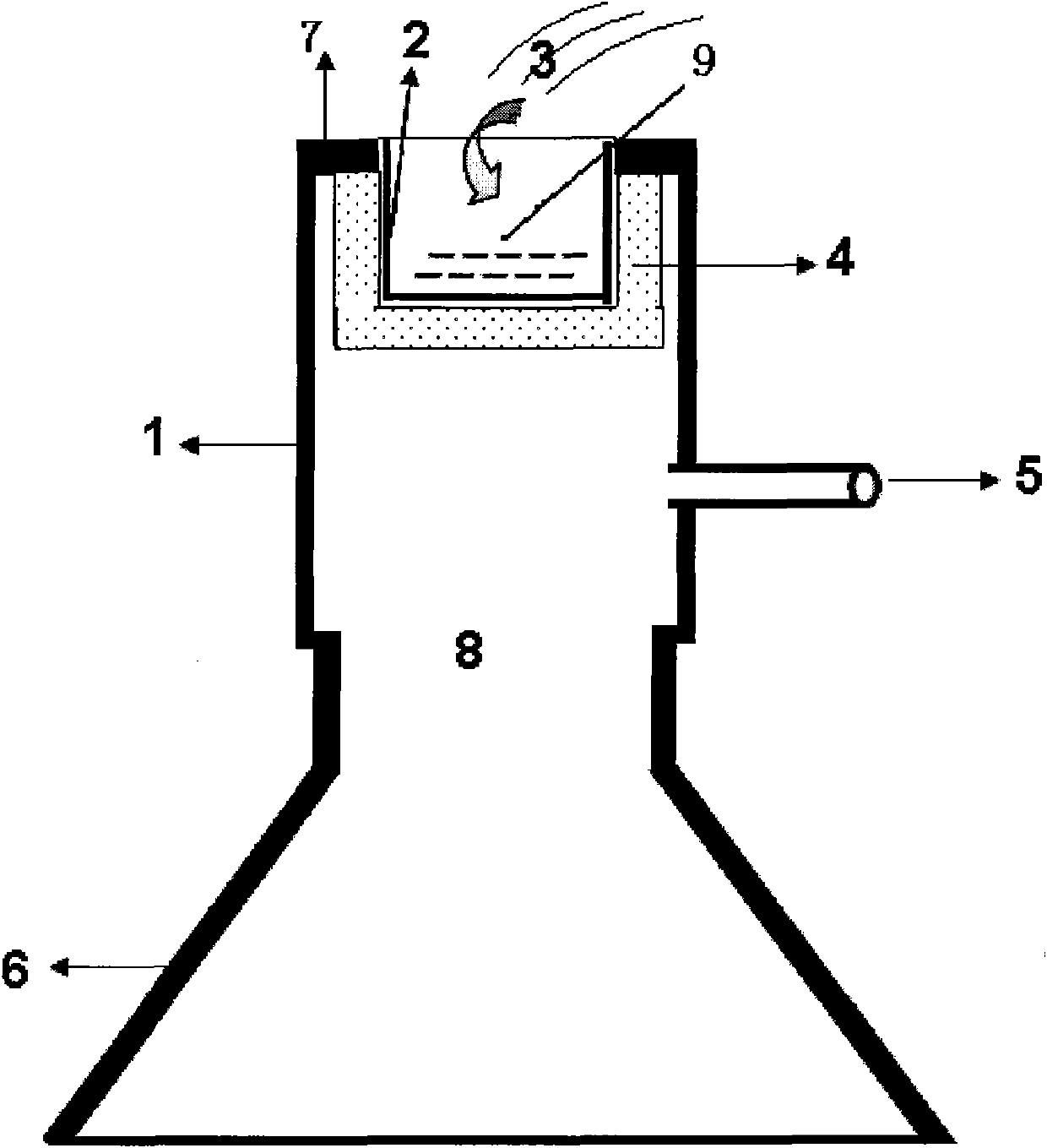

[0033] Such as figure 1 Shown, a kind of grouting forming device comprises vacuum chamber 8, microporous membrane 2, concave support 4, is characterized in that concave support 4 is cylindrical, with cylindrical concave groove at the upper end, concave support 4 It is made of porous ceramic material; the vacuum chamber 8 is a container, the upper half of which is open in a cylindrical shape, the upper end is an inward opening 7, and the lower end is closed in a circular platform shape, and there is an air extraction hole 5 in the middle of the upper half of the end. 5 is connected with a vacuum pump; the microporous filter membrane 2 is cylindrical, with an open upper end, and a filter membrane at the lower end and its periphery; the microporous filter membrane 2 fits with the concave groove on the concave support 4 and can be placed in a In the concave groove of the support 4, the close attachment is realized to jointly form the body space 9; the upper edge of the concave sup...

Embodiment 2

[0036] A method for grouting molding using the above grouting molding device, the steps are as follows:

[0037] (1) Preparation of YAG nanopowder

[0038] Yttrium-aluminum ions are mixed according to the molar ratio of 3:5 to obtain precursor solution 500ml, and its ion concentration is 0.5 mol / liter, which is added dropwise to 1500 milliliters of 2 mol / liter ammonium bicarbonate solution, and the precipitate obtained is washed with water and After washing with alcohol, dry at 80°C to obtain the precursor powder, which is calcined at 1100°C for 2 hours to obtain YAG nanopowder with an average particle size of 100 nanometers;

[0039] (2) Preparation of slurry

[0040]Add deionized water to the prepared YAG nanopowder, and add dispersant, binder and sintering aid at the same time,

[0041] Its components are: YAG nano powder is 80 grams, deionized water is 80 grams, dispersant is 0.15 grams, binder is 0.15 grams, sintering aid is 0.2 grams,

[0042] Utilize high-purity alum...

Embodiment 3

[0049] A method for grouting molding using the above grouting molding device, the steps are as follows:

[0050] (1) Preparation of YAG nanopowder

[0051] Yttrium-aluminum ions are mixed according to the molar ratio of 3:5 to obtain precursor solution 500ml, and its ion concentration is 0.5 mol / liter, which is added dropwise to 1500 milliliters of 2 mol / liter ammonium bicarbonate solution, and the precipitate obtained is washed with water and After washing with alcohol, dry at 80 degrees to obtain the precursor powder, which is calcined at 1000 degrees for 4.5 hours to obtain YAG nano-powder with an average particle size of 100 nanometers;

[0052] (2) Preparation of slurry

[0053] Add deionized water to the prepared YAG nanopowder, and add dispersant, binder and sintering aid at the same time,

[0054] Its components are: YAG nano powder is 40 grams, deionized water is 40 grams, dispersant is 0.1 grams, binder is 0.1 grams, sintering aid is 0.15 grams,

[0055] Utilize h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com