High strong weather resistance cold rolling container coating plate laser welding process

A laser welding and container technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficult welding effect, difficult assembly accuracy, and easy occurrence of spatter, so as to achieve easy and accurate positioning, simplify welding equipment, The effect of thermal deformation and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The high-strength weather-resistant cold-rolled clad plate used is the ZAM plate produced by Nisshin Company, the surface coating is Al-Mg-Zn coating (containing 6% Al and 3% Mg, and the rest is Zn), the thickness specification is 0.8mm, and the chemical composition of the substrate is as follows : C ≤ 0.15, Mn ≤ 0.9, Si ≤ 0.55, P ≤ 0.035; S ≤ 0.035; Ti: ≤ 0.15; Cr ≤ 1.2; Cu ≤ 0.5, the rest is Fe and unavoidable impurities. The mechanical properties of ZAM plates are as follows: Yield strength R p0.2 ≥335MPa, tensile strength R m ≥440MPa, elongation A≥18%.

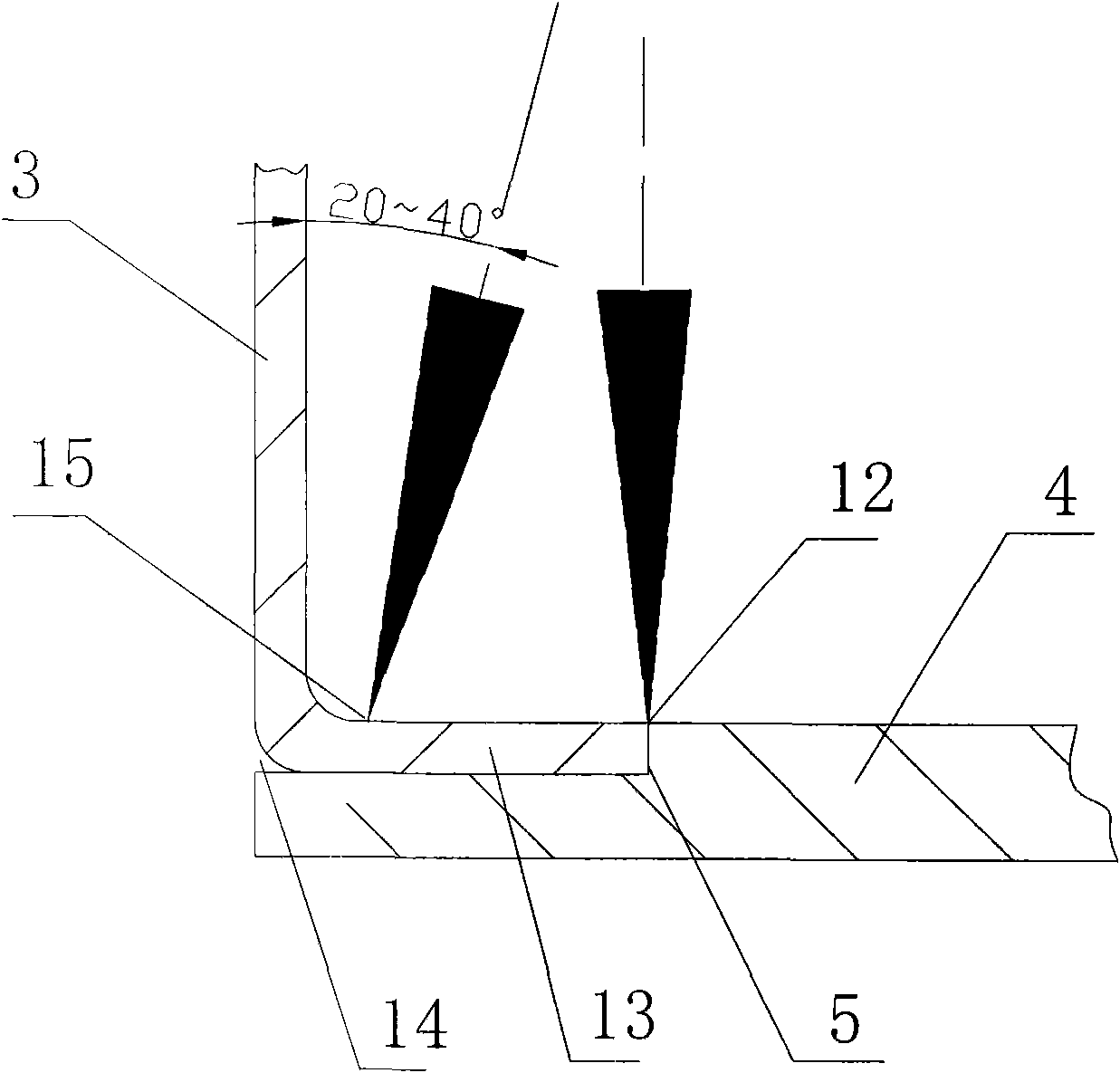

[0047] Lap welding: before welding according to figure 1 In the design of the middle joint, the welding edges of the upper and lower coated plates 1 and 2 are respectively bent into a V shape with the tip facing upward. The bending angles are 120 degrees for the upper coated plate 1 and 150 degrees for the lower coated plate 2. The width of the bent part Keep the same, both are 8mm. After splicing the bending par...

Embodiment 2

[0050] The clad plate is the same as in Example 1.

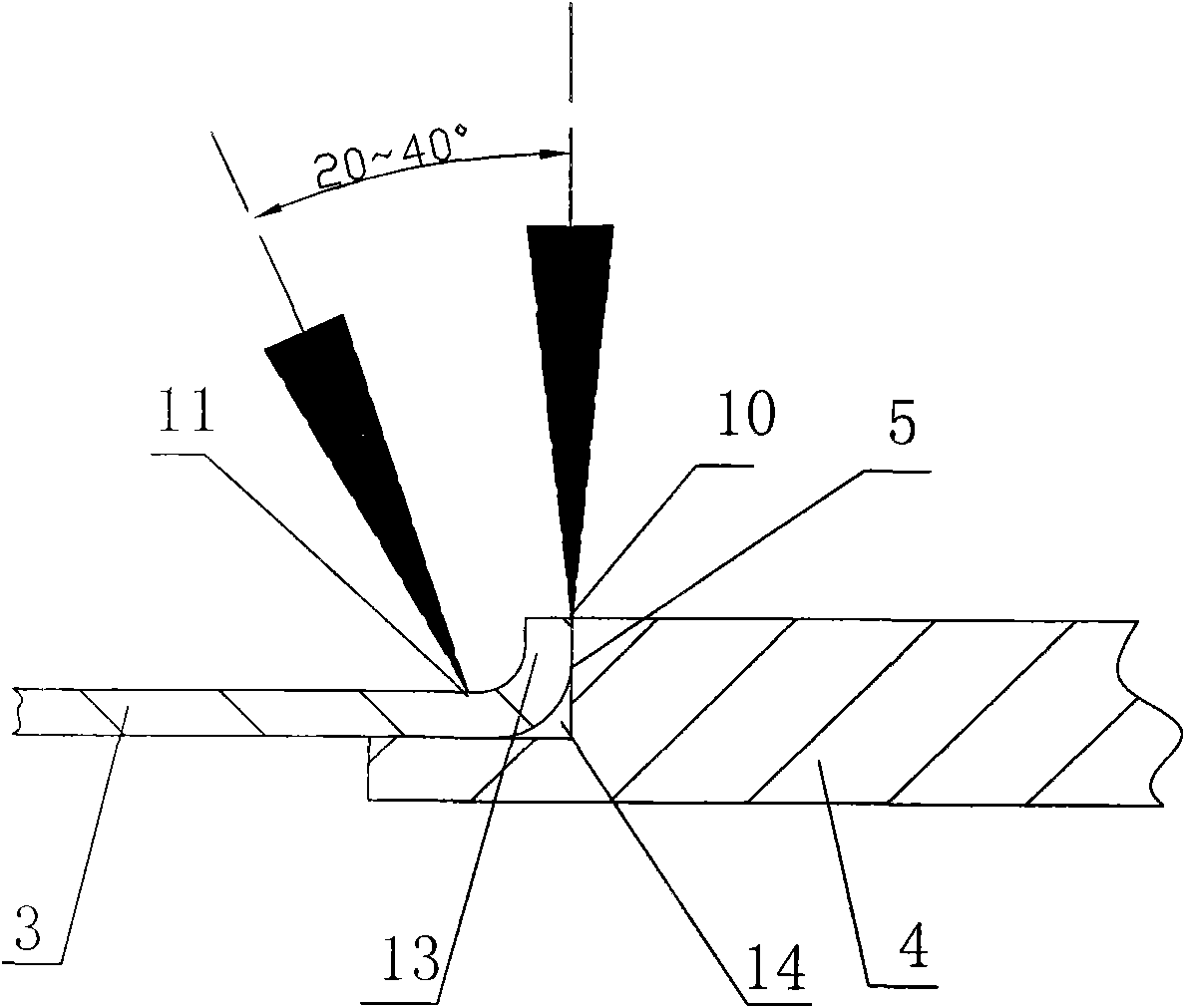

[0051] Fillet welding: before welding according to figure 2 In the design of the middle joint, the welding edges of the upper and lower coated plates 1 and 2 are crimped respectively, the crimping angle is 90 degrees, the crimping width is 8 mm, and the rounded corners of the crimping 13 of the lower clad plate 2 are smaller than those of the upper clad plate 1 The curling 13 is rounded, and then the curling 13 of the upper and lower two coated plates 1 and 2 are spliced correspondingly, and then the mechanical clamps are used to rigidly fix and clamp the plates. After splicing, a gap of 1 mm is formed between the two curling edges of the coated plates. 14. The fiber laser is used to transmit the laser light to the welding area with an optical fiber. The defocus of the beam is -0.5mm. The welding robot is used to hold the welding torch and move along the center of the weld for welding. Weld C8 and Weld D9, welding posit...

Embodiment 3

[0054] The high-strength weather-resistant cold-rolled clad plate used is the ZAM plate produced by Nisshin Company, and the chemical composition and specifications of the base material are the same as those in Example 1. The upper beam (that is, profile 4) is made of CortenA plate with a thickness of 2.0mm, and the chemical composition (wt%) is as follows: C 0.12, Mn 0.2-0.5, Si0.25-0.75, P 0.07-0.15; S 0.05; Ni: 0.65; Cr 0.30-1.25; Cu0.25-0.55, the rest is Fe and unavoidable impurities. The mechanical properties of Corten A plate are: yield strength R p0.2 =345MPa, tensile strength R m =480MPa, elongation A=22%,

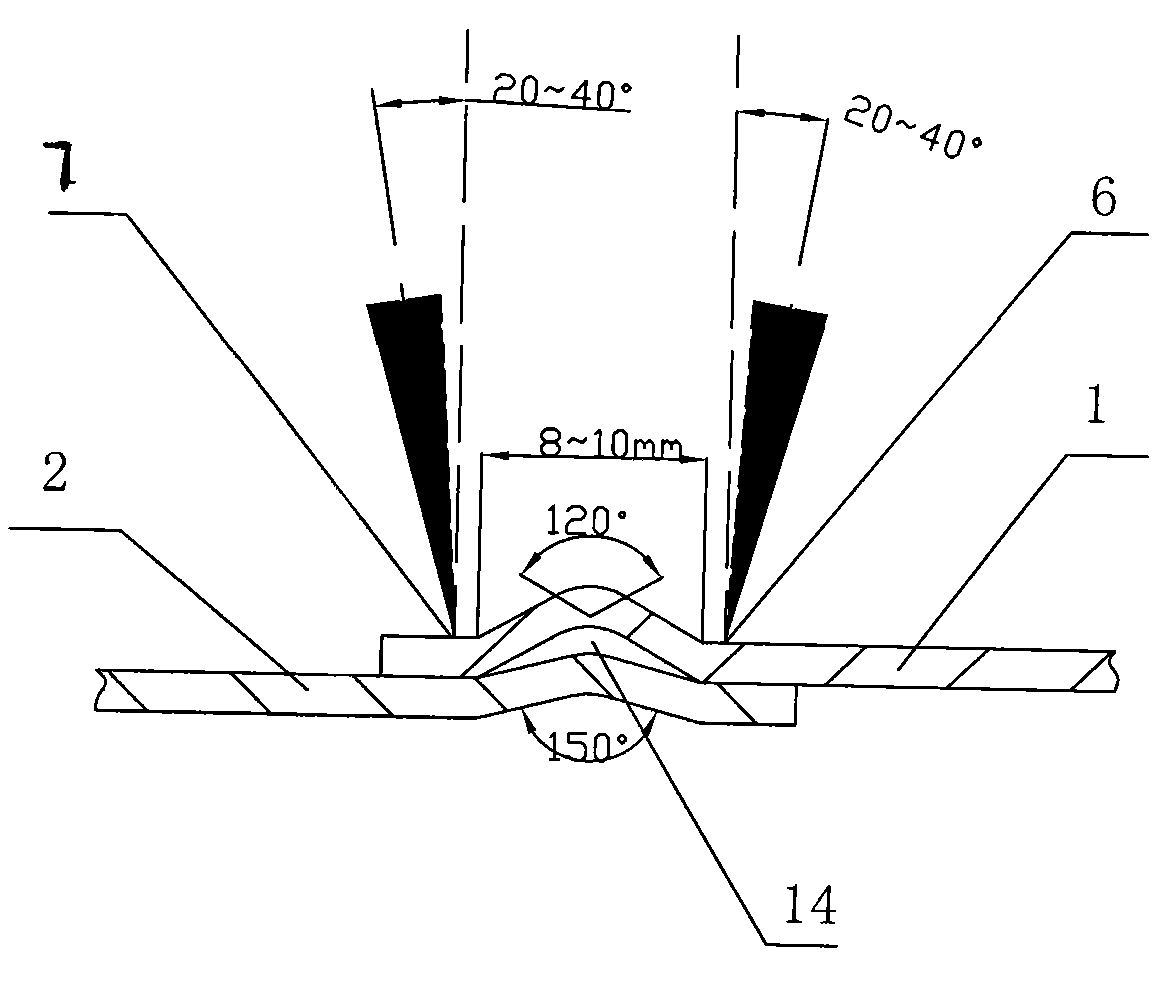

[0055] Lap welding: before welding according to image 3 In the design of the middle joint, the welding edge of the coated plate 3 is curled, the curling angle is 90 degrees, the width of the curling 13 is 2mm, and the radius of the fillet of the curling 13 is 2mm, and the welding part of the profile 4 is processed and the curling 13 The right-angled assembly g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com