Rapid testing device of readiness of thermocouples of crystallizer of continuous casting machine

A technology of testing devices and thermocouples, applied in the configuration of indicating equipment/measuring equipment, casting equipment, metal processing equipment, etc., can solve the problems of wasting manpower and time, and achieve the effect of improving efficiency and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

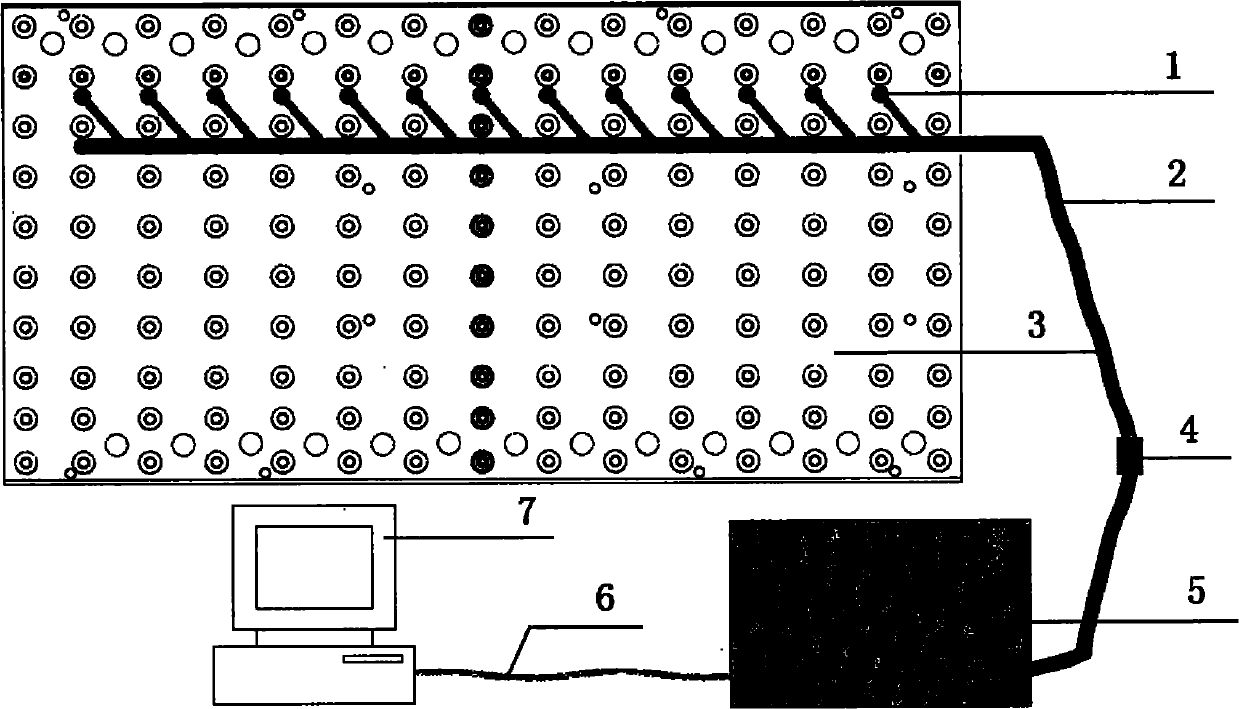

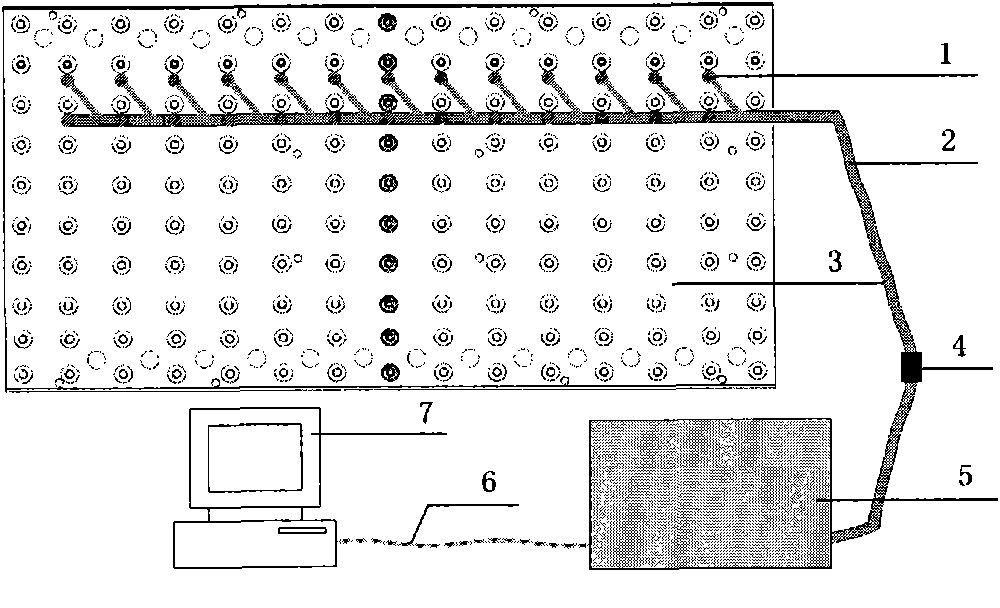

[0017] 1. Transmit all the thermocouple signals installed on the copper plate to the terminals of the PLC control cabinet. In order to save the time of replacing the crystallizer each time, the compensation wires of the thermocouples will adopt the method of multi-core quick plug synthesis bus cable, so that the thermocouples can be disassembled It is very convenient and fast. The test device also adopts the multi-core quick plug method, and the other end adopts the fixed terminal method in the PLC control cabinet, and connects all the signal lines of the thermocouples numbered according to the construction drawings to the specified terminals.

[0018] 2. For the configuration of electrical components in the PLC control cabinet, determine the number of suitable thermocouple acquisition modules according to the number of thermocouples, and install the PLC power module, CPU module, thermocouple acquisition module, etc. into the cabinet. According to the serial number of the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com