Ceramic honeycomb structures

A technology of honeycomb structure and ceramic honeycomb, which is applied in ceramic products, filtration and separation, household appliances, etc., and can solve problems such as poor thermal stability and poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

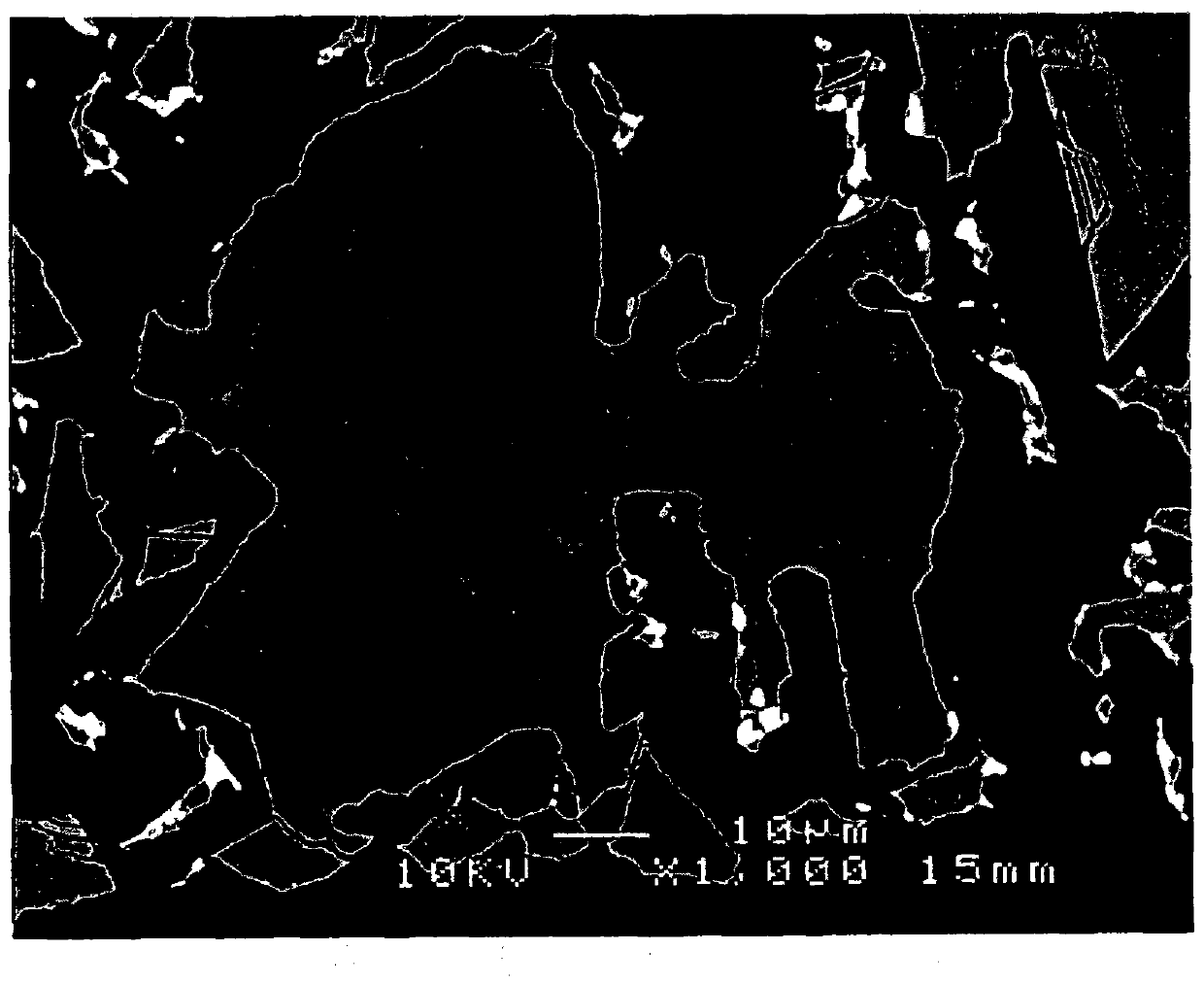

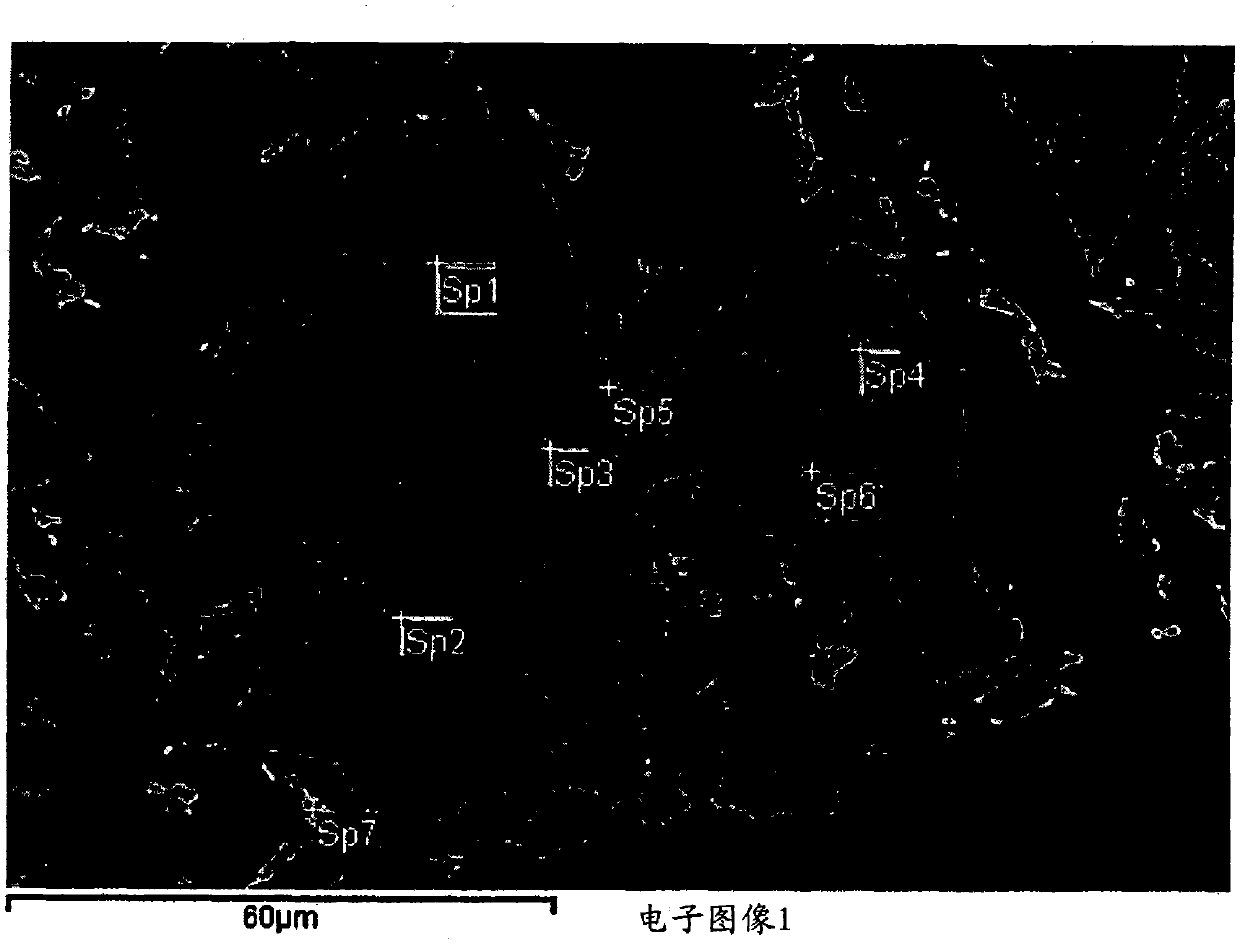

Method used

Image

Examples

preparation example Construction

[0116] Preparation of raw materials:

[0117] For the application of the present invention, the solid mineral compounds (andalusite, alumina, titania, graphite, mullite, tialite, etc.) use. Corresponding preparations are commercially available and known to those skilled in the art. For example, powdered andalusite having a particle size range suitable for the present invention is available under the trade name (Damrec), powdered graphite having a particle size range suitable for the present invention can be obtained under the trade name (Timcal), powdered alumina and alumina dispersions are available from Degussa, and powdered titania and titania dispersions are available from Millennium Chemicals. Selected cuts of commercially available materials may, if desired, be obtained by techniques known in the art, such as fractionation techniques (eg, sieving).

[0118] Alternatively, mullite and tialite can be prepared by reacting appropriate mineral precursor compounds at ele...

Embodiment 1

[0166] Example 1: Preparation of Extrudable Mixtures and Ceramic Honeycomb Structures of the Invention

[0167] Step 1: Preparation of Extrudable Mixture and Extrusion Method

[0168]Mix the raw materials listed in Table 1 in a conventional mixer (Eirich mixer) to obtain an extrudable paste which can be passed through a conventional extruder (Dorst V15 or V20 extruder) equipped with a suitable die. Extruded to obtain a green honeycomb body.

[0169] Table 1: Composition of Extrudable Mixtures

[0170] raw material

FIDI 20

FIDI 23

FIDI 24

FIDI 25

%

%

Contain >10μm~55

μm of selected andalusite

Contain >20μm~55μm

selected andalusite

andalusite

53.8%

53.9%

53.9%

53.9%

15.0%

15.0%

15.0%

15.0%

3.0%

3.0%

3.0%

3.0%

h 2 o

4.0%

0.0%

0%

0%

Titanium Dioxide Dispersion

4.0%

12.4%

12....

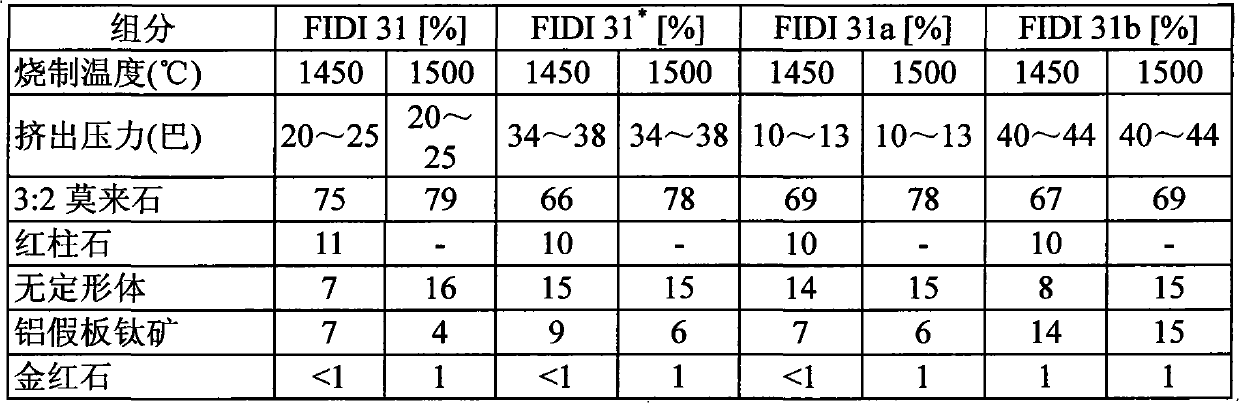

Embodiment 2

[0206] Example 2: Preparation of Extrudable Mixtures of the Invention

[0207] Mix the raw materials listed in Table 4 in a conventional mixer (Eirich mixer) to obtain an extrudable paste which can be passed through a conventional extruder (Dorst V15 or V20 extruder) equipped with a suitable die Extruded to obtain a green honeycomb body.

[0208] Table 4: Composition of raw materials

[0209] raw material

FIDI 30

FIDI 30

Contain > 10μm ~ 55μm selected

andalusite

Contains > 20μm ~ 55μm

andalusite

andalusite

53.8%

53.8%

graphite

13.0%

13.0%

5.0%

5.0%

h 2 o

0%

0%

Titanium Dioxide Dispersion

12.4%

12.4%

Aluminum Oxide Dispersion

10.5%

10.5%

Additives (plasticizers and lubricants)

5.2%

5.2%

total:

100.00%

100.00%

[0210] Andalusite as commodity The form of KF (Damrec) is used. Graphite as a commodity The form of KS75 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com