Trench-type Schottky-barrier diode rectifier and preparation method

A technology of diode rectification and Schottky potential, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve the problem of increased reverse leakage, poor gap filling ability, and decreased reverse blocking ability, etc. problem, to achieve the effect of high voltage reverse blocking ability, overcoming tip discharge effect, and strong gap filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: A trench type Schottky barrier diode rectifier device and its manufacturing method

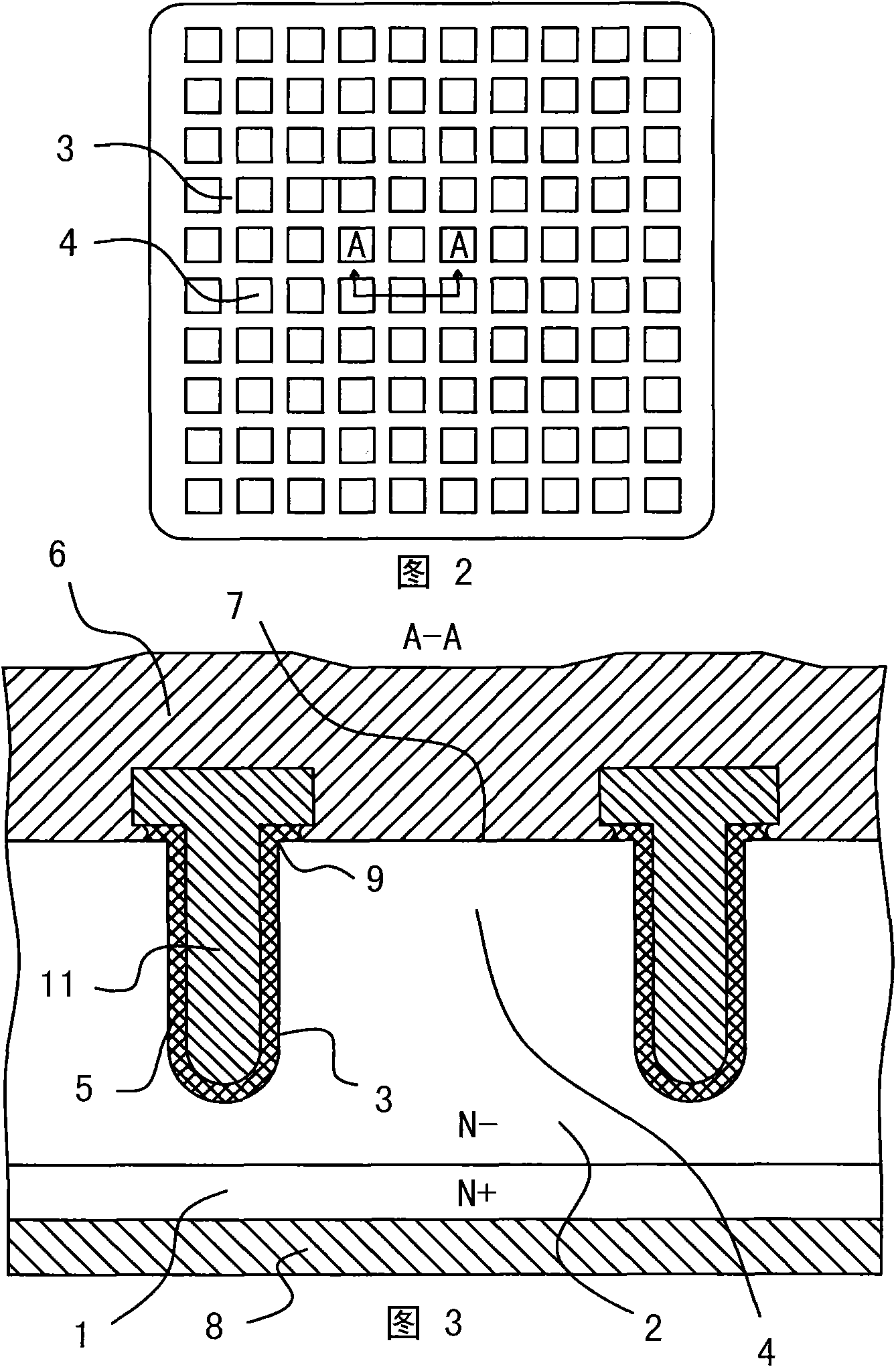

[0037] like figure 2 and image 3 Shown, the trench type Schottky barrier diode rectifier device structure of the present invention is: on the top view plane (see figure 2 ), the active region of the device consists of several Schottky barrier diode cells connected in parallel. On a longitudinal section through the center of the Schottky barrier diode unit cell (see image 3 ), each Schottky barrier diode unit cell is composed of lower metal layer 8, N+ monocrystalline silicon substrate 1, N- epitaxial layer 2 and upper metal layer 6 from bottom to top, wherein in the N- epitaxial On the upper part of the layer 2, grooves 3 are spaced apart laterally, and the N-epitaxial layer 2 region between two adjacent grooves 3 forms an N-monocrystalline silicon boss structure 4, and the top surface of the boss structure 4 is connected to the upper metal layer 6 The contact forms ...

Embodiment 2

[0057] Example 2: A Trench Schottky Barrier Diode Rectifier Device and Manufacturing Method

[0058] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: from the top view plane of the rectifier device, the pattern of the trench 3 is different, the embodiment 1 is grid-like, and the Schottky barrier diode cells are arranged in an array small square. And the figure of present embodiment groove 3 from Figure 4 It can be seen in the figure that they are strips parallel to each other, and the Schottky barrier diode cells are strips parallel to each other. Other contents are the same as those in Embodiment 1, and will not be described again here.

[0059] Through Embodiment 1 and Embodiment 2, it can be seen that the planar layout and shape of the unit cell of the rectifier device can have other changes, such as the shape of the unit cell is prismatic, circular, triangular, etc., and the layout can be from the inside to the outside. size ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com