Construction method for rear planted wall steel tie

A technology for tying steel bars and construction methods, applied in construction, building construction, etc., can solve the problems that plague the construction quality of concrete frame structures, destroy the appearance quality of columns, and difficult to guarantee construction quality, so as to improve the overall construction period effect and reduce anchorage. Significant effect of length, economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Attached below figure 1 And table 1, table 2 give an example:

[0008] like figure 1 As shown, 1. Calibrate the hole position: use the electronic steel bar scanner to measure the specific position of the original steel bar at the anchorage part, and mark the planting bar hole position on the frame columns and beams with paint according to the design requirements.

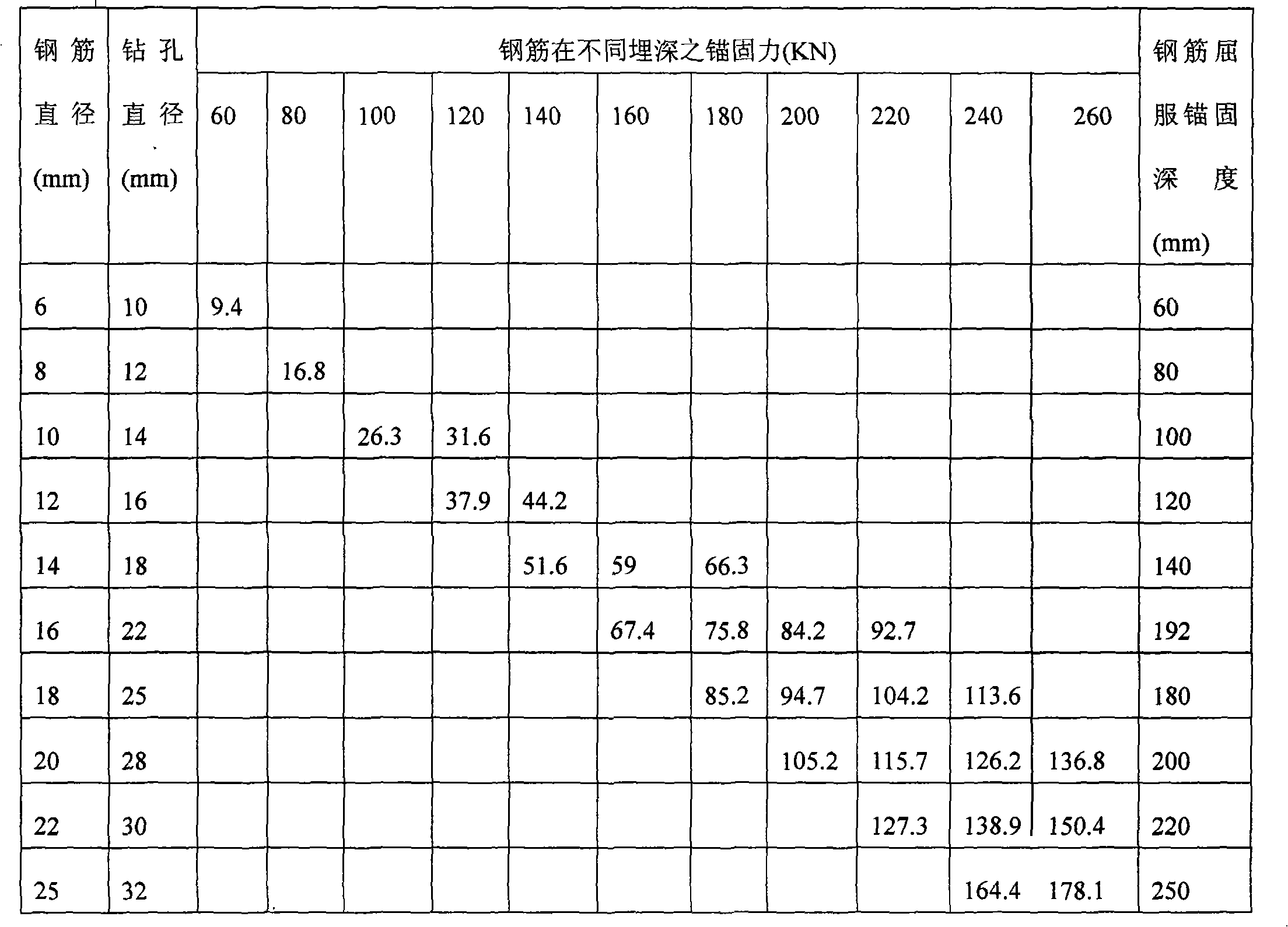

[0009] 2. Hole forming: Use electric hammer (impact drill) to drill holes. If the hole diameter and hole depth design are specified, follow the design and construction. If there is no basis, determine it according to the diameter of the steel bar to be planted. See Table 1.

[0010] 3. Cleaning the hole: first use thin steel bars to clean the stone chips, then use a brush to remove dust, and then use an electric fan to clean the hole. Oil should not be brought in, and the hole should be clean and dry.

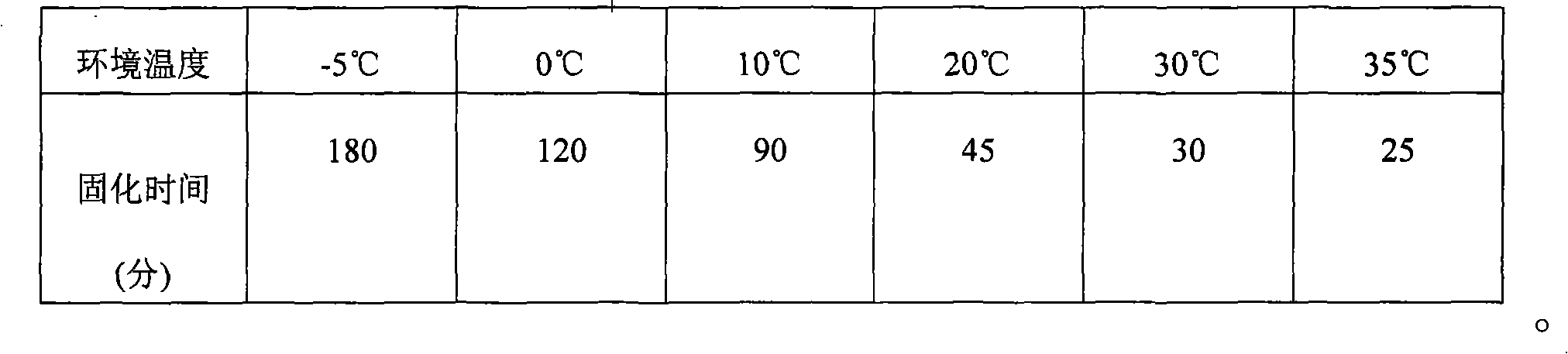

[0011] 4. Glue injection: Use a syringe with a gun tip. Before injection, the first rubber material extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com