Processing device of polyester and viscose blended yarn in binary structure and method thereof

A technology of binary structure and processing method, applied in spinning machine, yarn, textile and paper making, etc., can solve the problem of uncontrollable fiber mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

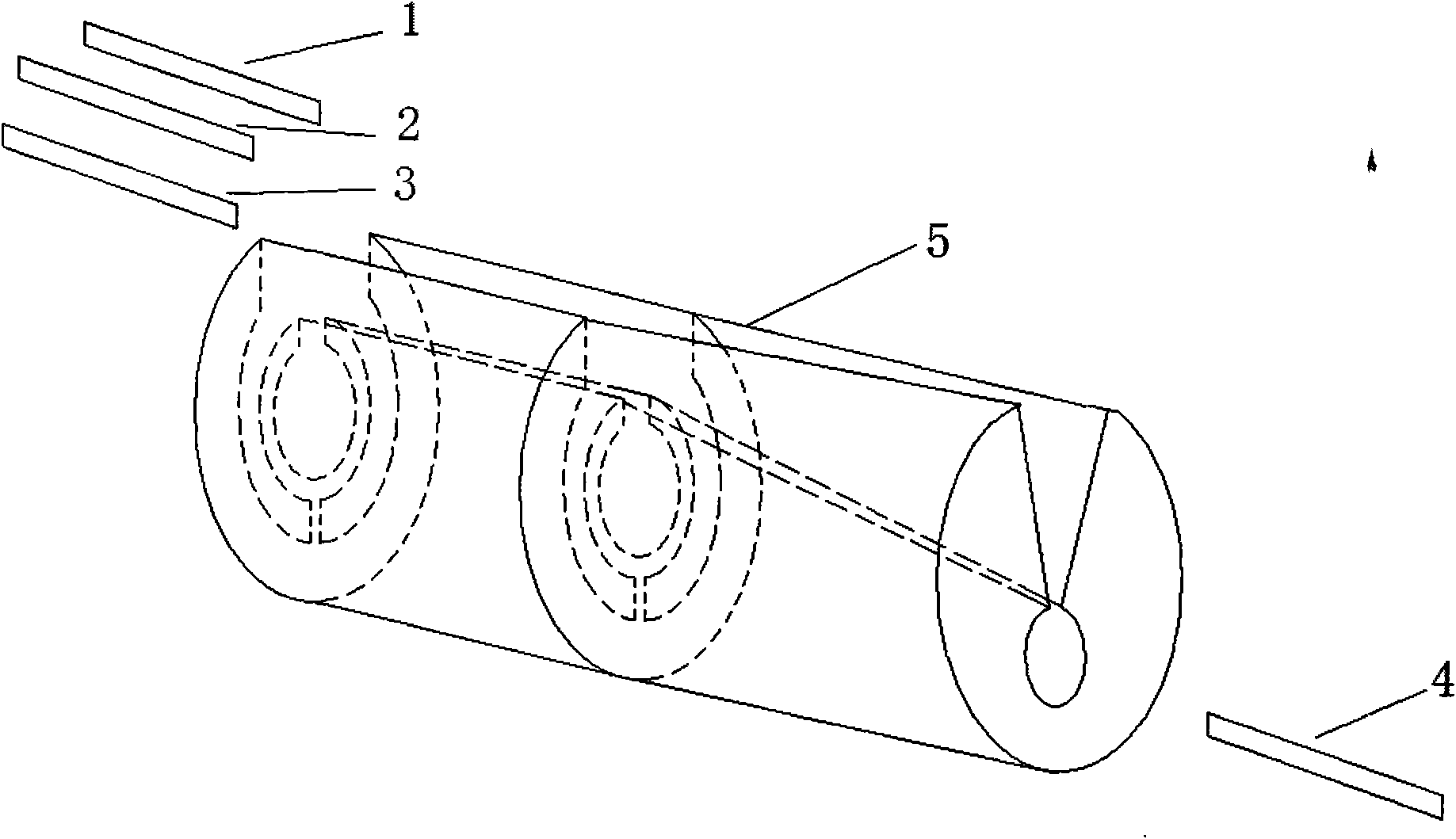

[0017] Such as figure 1 , Figure 5 As shown, two polyester rovings and one viscose roving are fed into the three-port collector 5 in parallel at a certain distance, and the two polyester rovings enter the entrances 6 and 7 on both sides respectively, and one viscose roving enters the middle entrance 8. After converging at the concentrator, a mixed roving sliver with viscose in the middle and polyester on the outside is formed. After passing through the rear roller 11, in order to prevent the roving from being scattered, it passes through the concentrator 10 with a V-shaped opening, and then twists after being drawn. In yarn formation, since polyester fibers of the same thickness are more rigid than viscose fibers, and the position is guaranteed, it can be ensured that the viscose fiber is the core fiber and the polyester fiber is the outer fiber in the final yarn.

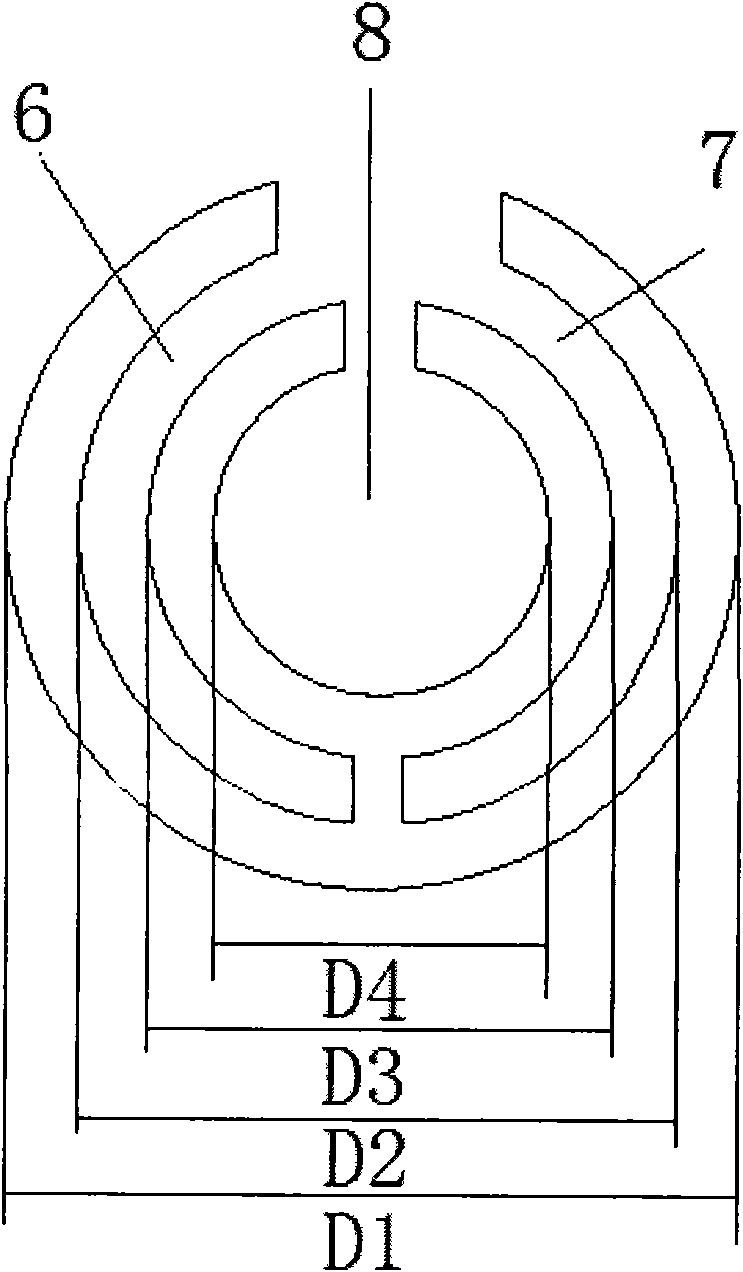

[0018] Such as figure 2 , image 3 As shown, in the three-port collector 5, the size of the outer opening o...

Embodiment 2

[0021] Such as figure 1 , Figure 5 As shown, two viscose rovings and one polyester roving are fed into the three-port collector 5 in parallel at a certain distance, and the two viscose rovings enter the inlets 6 and 7 on both sides respectively, and one polyester roving enters the middle inlet 8. After converging at this collector, a mixed roving sliver with polyester in the middle and viscose on the outside is formed. After passing through the back roller, in order to prevent the roving from being scattered, it passes through the V-shaped opening collector 10, and then is twisted into yarn after drafting. Since the rigidity of polyester fibers of the same thickness is greater than that of viscose fibers, in order to ensure that the polyester fibers can be placed in the core of the yarn, thinner polyester fibers can be used, and at the same time, the position is guaranteed to ensure that the viscose fibers in the final yarn can be obtained It is the core fiber, and the polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com