Dry white wine and aroma-enhancing brewing method thereof

A dry white wine and grape technology, applied in the field of wine processing, can solve the problems of low nutritional value of white wine, low utilization of flavor substances, lack of extraction of resveratrol, etc., to achieve the enhancement of a class of aroma and variety typicality, flavor Complexity, effects that increase complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

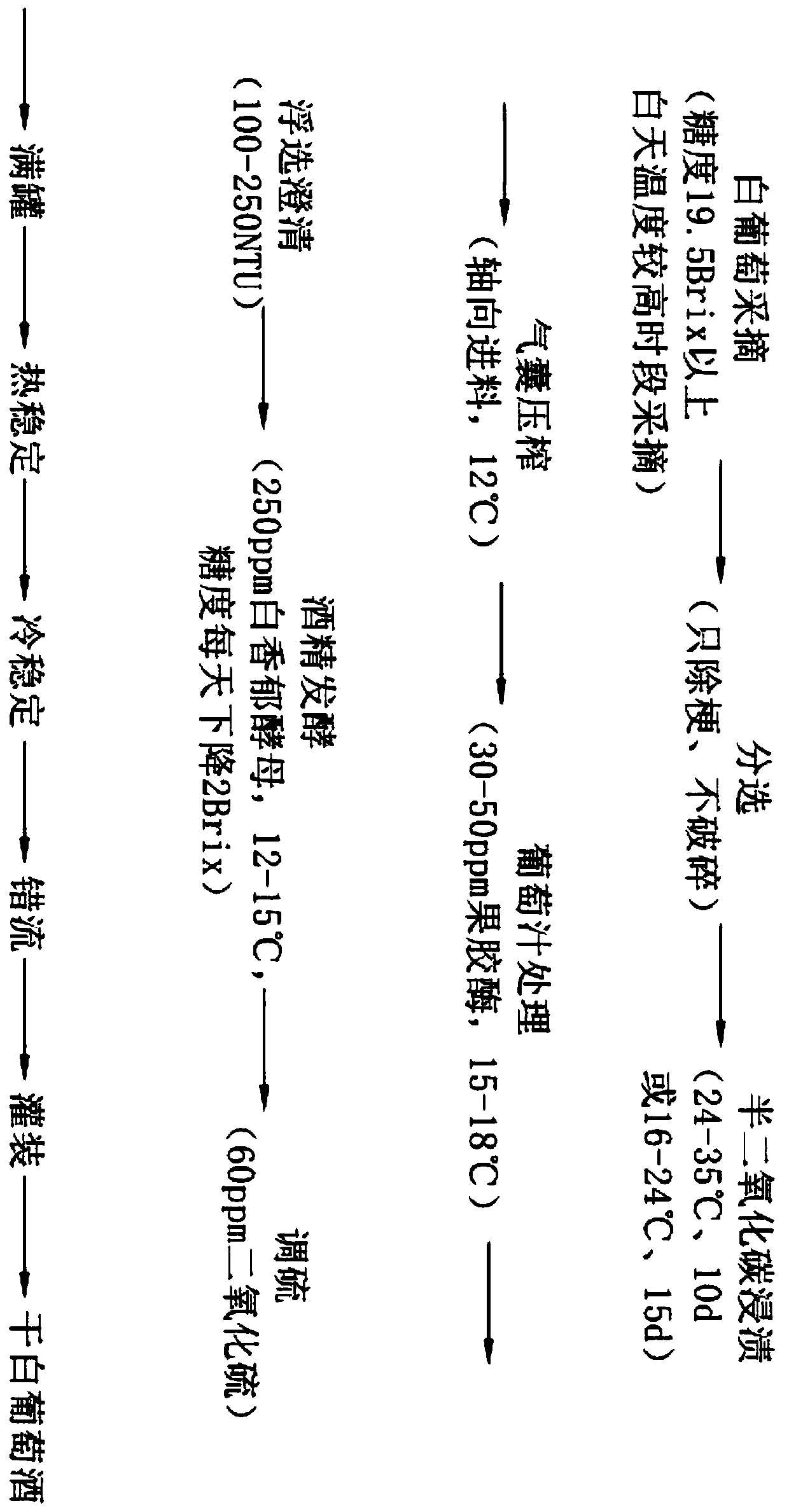

Embodiment Embodiment 1

[0055] One, embodiment embodiment 1: a kind of dry white wine adopts following method to brew to form:

[0056] (1) Requirements for raw materials: Choose Chardonnay grape varieties with a sugar content of 19.5brix or more. The grapes are required to have good maturity, a pH value of 3.2-3.5, a total acid content of 7.0-8.5g / L, and grapes that are fresh, disease-free, and mature. Good uniformity, no green fruit, moldy and rotten fruit, and no other foreign matter.

[0057] (2) Grape picking: Since semi-carbon dioxide impregnation requires a higher temperature, it is advisable to pick grapes at a time when the temperature is higher at noon; pick them by hand, avoid skin damage during the picking process, and ensure the ear and fruit to the greatest extent. To ensure the integrity of the grains, reduce the breakage rate, and weigh them after picking.

[0058] (3) Grape raw material treatment: Put the picked grapes into the destemming crusher, adjust the destemming crusher to de...

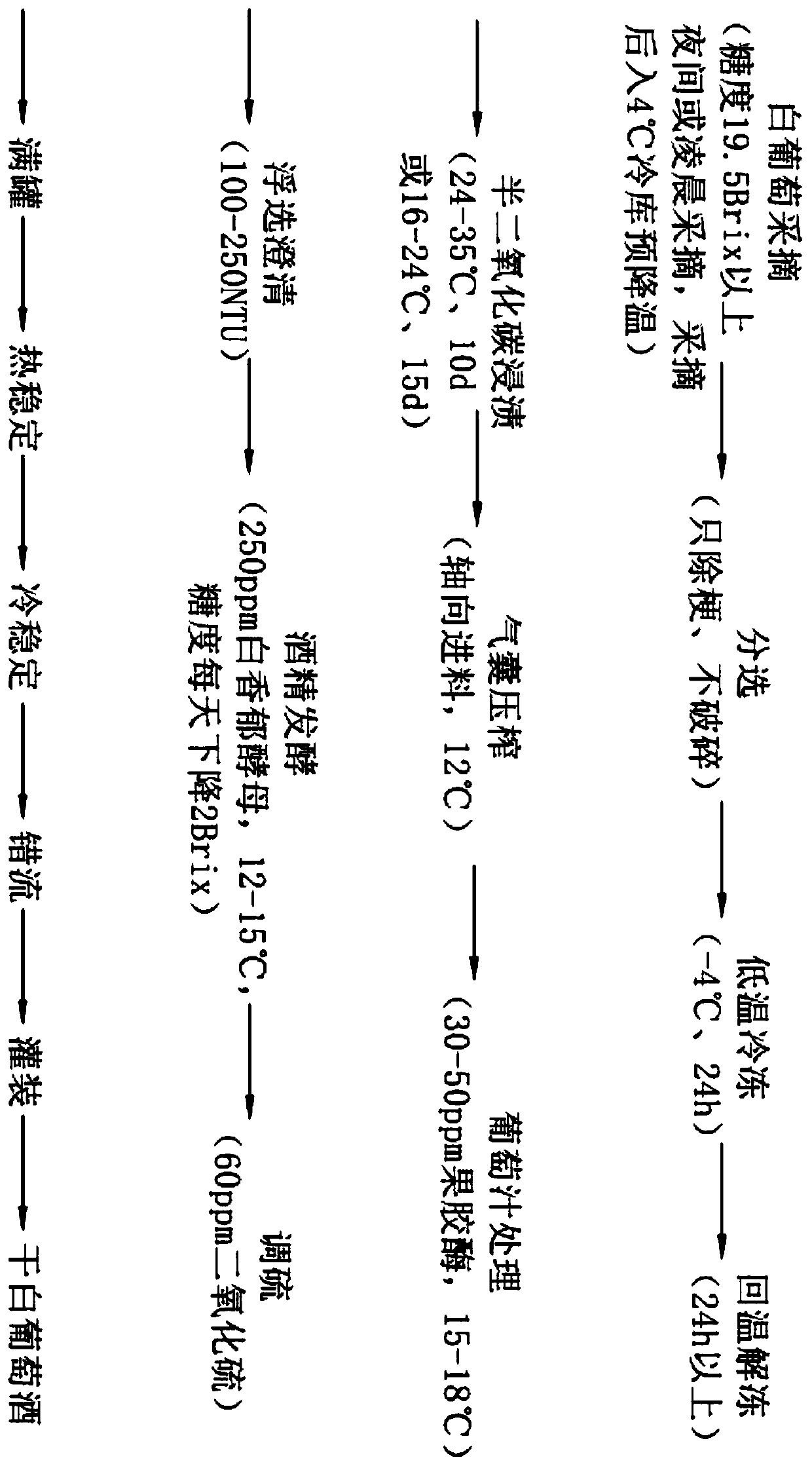

Embodiment 2

[0070] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the grape picking in step (2) should be carried out at night or in the early morning, the ambient temperature is lower than 20°C, and the grapes are picked into the cold storage for pre-cooling, reducing the temperature. The load per unit time of the refrigeration equipment in the follow-up process further improves the efficiency of entering the tank. The operating condition of the cold storage is 4°C, which has good thermal insulation performance. In addition, low-temperature freezing and temperature-returning treatment steps are added between step (3) grape raw material processing and (4) semi-carbon dioxide immersion, and its specific operations are as follows:

[0071] Low-temperature freezing: Choose a dipping tank (20T, 20KL) with small volume, good sealing and integrated cooling and heating temperature control system, destem the raw materials and put them into the tank whole, add sulfur ...

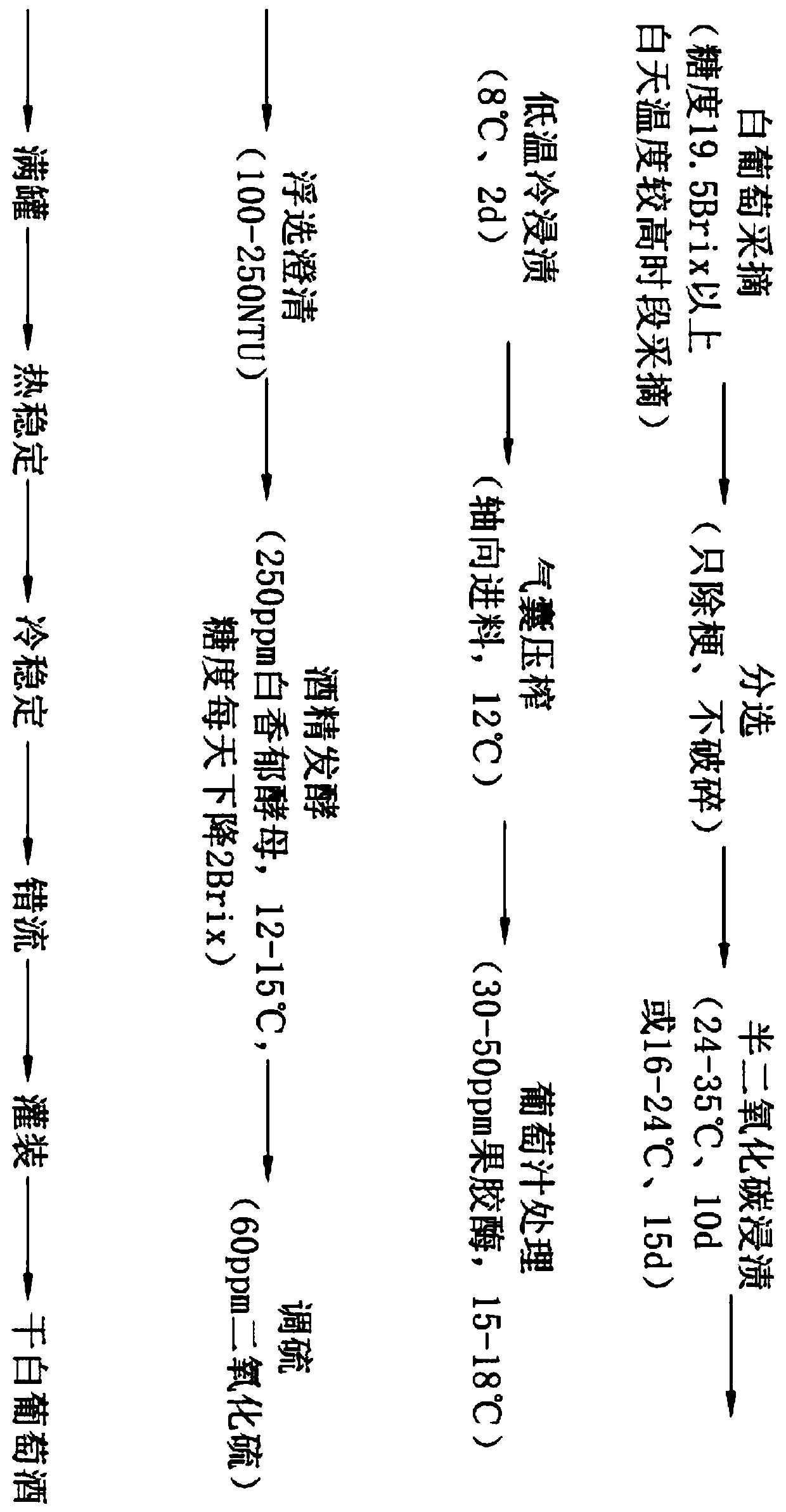

Embodiment 3

[0073] Embodiment 3: The difference between this embodiment and Example 1 is that the cold maceration process is increased between step (4) cold maceration and step (5) pressing, and its specific operation is as follows:

[0074] Cold maceration process: After the semi-carbon dioxide maceration, the must is transferred to the rotary fermenter through a peristaltic pump, and maceration enzymes (selected from X-Press or DSM Rapidase ), the addition amount is 20ppm, the temperature is controlled to 8°C, and the maceration lasts for 2 days. During the cold maceration process, an inert gas protection should be used to prevent the oxidation of the grape juice and avoid the loss of aroma substances. At the same time, the temperature should be strictly controlled below 10°C. Dissolution of phenolic substances from grape skins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com