Integrative method of two-stage acid leaching, washing and filter pressing for manganese powder pickle liquor

A manganese powder acid and leaching technology, applied in the direction of improving process efficiency, can solve the problems of surrounding water environment, soil environment pollution, practical processes that have not been produced and applied, endangering the health of residents, etc., and improve the utilization of manganese resources. efficiency, realize the concept of cleaner production, and reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

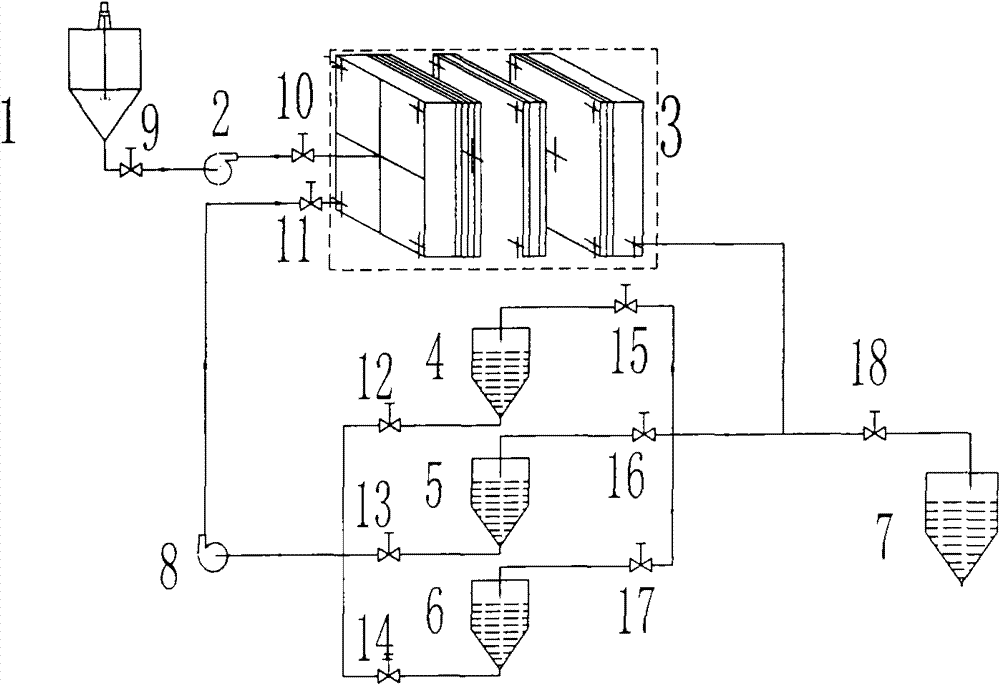

[0039] (1) Open the pump 2 and the control valves 9, 10, 18, inject the manganese powder pickling solution directly into the diaphragm filter press 3, and the press filtrate flows into the filtrate pool 7, when the filter residue is completely filled with the filter plate of the entire diaphragm filter press 3 chamber, stop pump 2, close control valves 9, 10, 18;

[0040] (2) Open the pump 8, open the control valves 11, 12 and 15, inject the anolyte (the concentration of manganese is 12.6g / L, the concentration of sulfuric acid is 46g / L) into the membrane filter press 3, and the washing pressure is controlled at 0.1Mpa , carrying out two-stage acid leaching and circular washing, the anolyte washing water flows to the anolyte pool 4; after 5 minutes, the pump 8 and the control valves 11 and 12 are closed;

[0041] (3) Press filter the filter cake, close the control valve 15, and complete the operation.

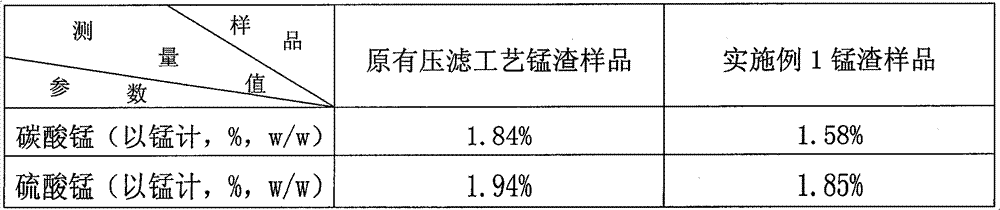

[0042] The conclusion is as follows Table 1

[0043] Table 1: Data Analys...

Embodiment 2

[0047] (1) Open the pump 2 and the control valves 9, 10, 18, inject the manganese powder pickling solution directly into the diaphragm filter press 3, and the press filtrate flows into the filtrate pool 7, when the filter residue is completely filled with the filter plate of the entire diaphragm filter press 3 chamber, stop pump 2, close control valves 9, 10, 18;

[0048](2) Open the pump 8, open the control valves 11, 12 and 15, inject the anolyte (the concentration of manganese is 12.7g / L, the concentration of sulfuric acid is 48g / L) into the membrane filter press 3, and the washing pressure is controlled at 0.28Mpa , carry out two-stage acid leaching and cycle washing, and the anolyte washing water flows to the anolyte pool 4; after 30 minutes, close the control valves 12 and 15;

[0049] (3) Open the control valves 13 and 16, inject the low-concentration manganese-containing solution (the manganese-containing concentration is 8g / L) into the diaphragm filter press 3, keep t...

Embodiment 3

[0056] (1) Open the pump 2 and the control valves 9, 10, 18, inject the manganese powder pickling solution directly into the diaphragm filter press 3, and the press filtrate flows into the filtrate pool 7, when the filter residue is completely filled with the filter plate of the entire diaphragm filter press 3 chamber, stop pump 2, close control valves 9, 10, 18;

[0057] (2) Open the pump 8, open the control valves 11, 12 and 15, add sulfuric acid in the anolyte (concentration of manganese is 12.5g / L), so that the concentration of sulfuric acid in the anolyte is 60g / L; In the filter 3, the washing pressure is controlled at 0.6Mpa, and the two-stage acid leaching and one-time washing are carried out, and the anolyte washing water flows to the anolyte pool 4; after 120 minutes, the control valves 12 and 15 are closed;

[0058] (3) open control valve 13 and 16, add sulfuric acid in low-concentration manganese-containing solution (manganese-containing concentration is 8g / L), make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com