Waste lead storage battery acid type wet method process

A waste lead-acid battery, wet treatment technology, applied in the direction of battery recycling, process efficiency improvement, waste collector recycling, etc., can solve problems such as complex process flow, to overcome complex process flow, large market value, and reduce total cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

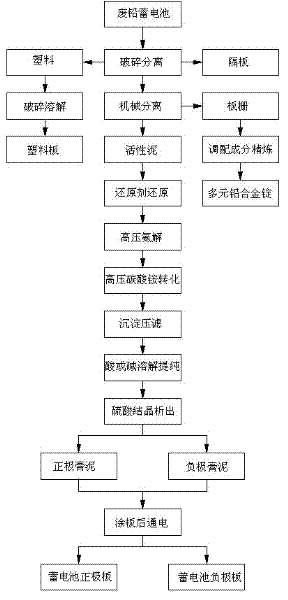

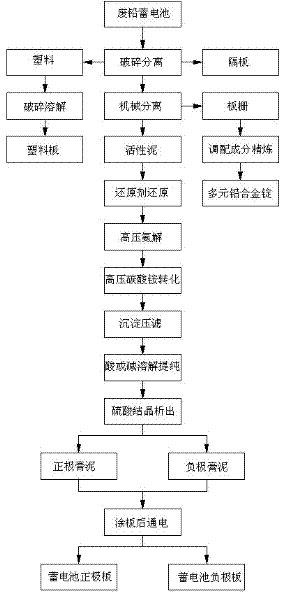

[0022] Embodiment 1: as figure 1 Shown, a kind of waste lead storage battery acid type wet treatment process, comprises the following steps:

[0023] 1) Crushing waste lead-acid batteries manually or with a crusher to separate sulfuric acid, plastic shells and separators in waste lead-acid batteries, and recycle and purify the separated plastic shells and separators according to the existing technology. Among them, the plastic shell can be remade into a plastic plate after being broken and dissolved;

[0024] 2) Transfer the remaining waste lead-acid batteries after the crushing treatment in step 1) to a mechanical separator and use vibration flotation method for treatment, and obtain grids and active mud after separation, wherein the grids are formulated and refined It can be made into multi-element lead alloy ingots; it should be noted that the crusher, mechanical separator and vibration flotation method mentioned in step 1 and step 2 all have existing common equipm...

Embodiment 2

[0028] Embodiment 2: Another kind of waste lead storage battery processing technology, its steps a, b are the same as steps 1, 2 of embodiment 1, and start to adjust from step c, the scheme of its adjustment is as follows:

[0029] C, carry out ionized reduction treatment with the hydrogen peroxide of 17% with mass ratio concentration earlier with described active mud, then transfer to the first autoclave and dissolve with ammonia solution under 7 atmospheric pressures, then transfer to the second autoclave The pressure is 5 atmospheres, and the temperature is 100°C for conversion with ammonium carbonate, and sedimentation and pressure filtration at normal temperature and pressure;

[0030] d. Dissolving and purifying the precipitate obtained in step c with sodium hydroxide having a mass ratio concentration of 35% at a temperature of 45°C, and then precipitating and crystallizing with a sulfuric acid solution, thereby obtaining positive electrode paste and negative elec...

Embodiment 3

[0032] Embodiment 3: Another kind of waste lead storage battery processing technology, its steps ①, ② are identical with the steps 1, 2 of embodiment 1, and start to adjust from step ③, the scheme of its adjustment is as follows:

[0033]③ The active mud is first ionized and reduced with a ferrous sulfate solution with a mass ratio concentration of 13%, then transferred to the first autoclave and dissolved with ammonia solution under 7 atmospheric pressures, and then transferred to the second autoclave Transformation is carried out with ammonium carbonate in an environment with a pressure of 5 atmospheres and a temperature of 80°C, and precipitation and pressure filtration at normal temperature and pressure;

[0034] ④ Dissolve and purify the precipitate obtained in step ③ with potassium hydroxide with a mass ratio concentration of 32% at a temperature of 50°C, then precipitate and crystallize with sulfuric acid solution, and then obtain positive electrode paste and negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com