Method for purifying trans-anethole

A kind of technology of trans-anethole and purification method, applied in the purification field of trans-anethole, can solve the problems of oxidation or polymerization reaction of anethole, large solvent consumption, large consumption of organic solvent and energy consumption, etc. Biological activity, avoiding the use of organic solvents, the effect of solving product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

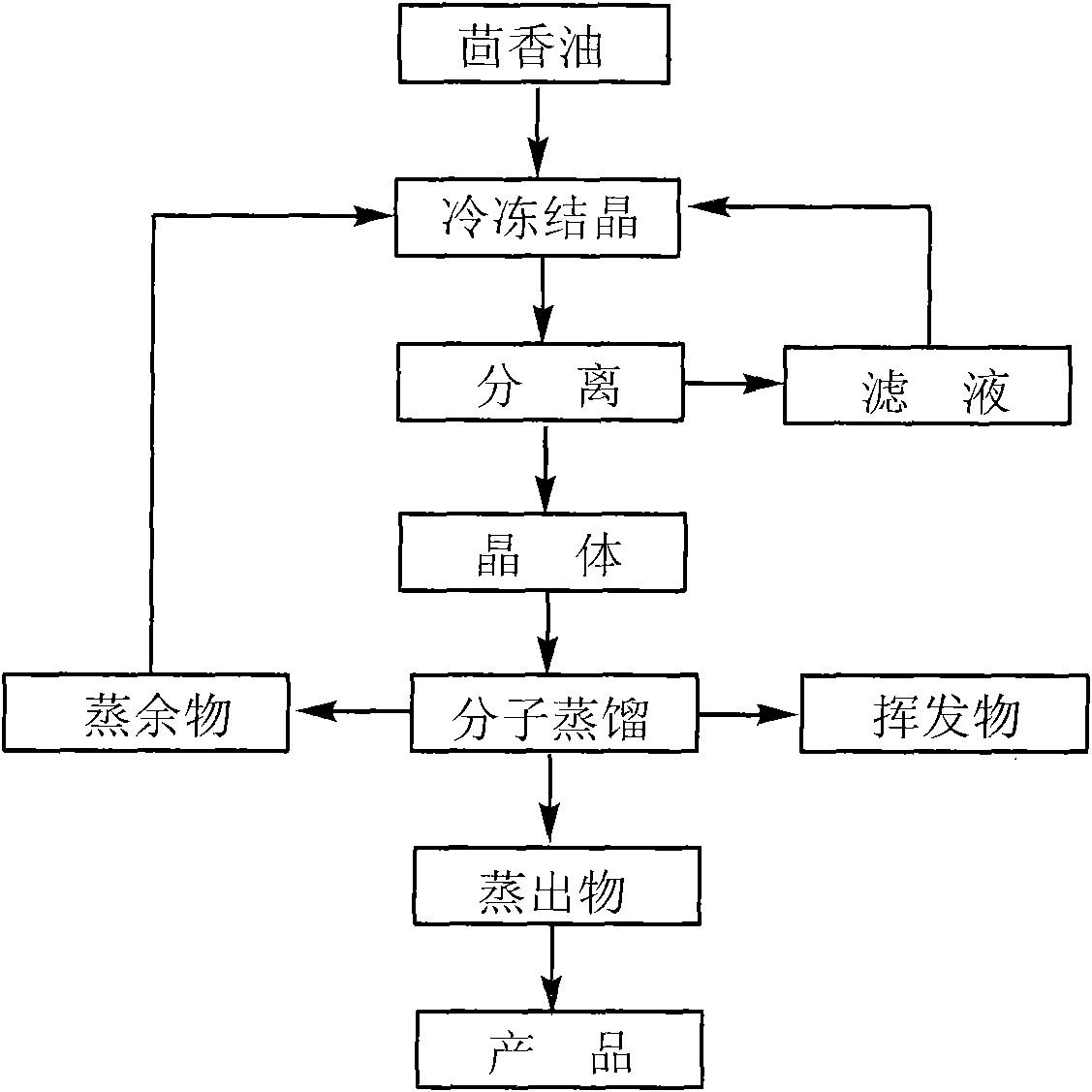

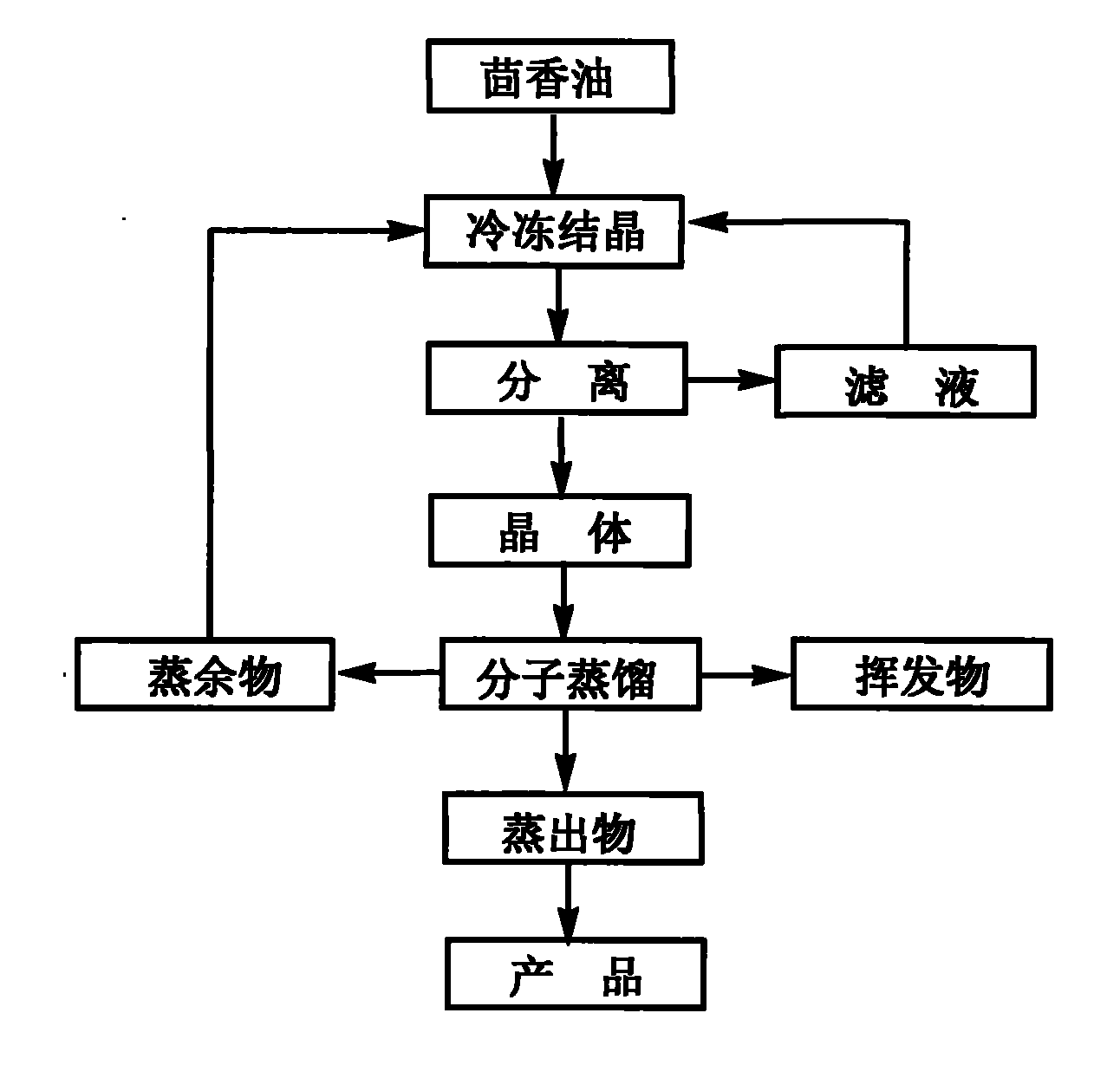

Method used

Image

Examples

Embodiment 1

[0021] Place the beaker containing 100g of fennel oil in a low-temperature environment of -25°C and freeze for 8 hours, quickly crush the frozen body to 10 mesh, and separate it by suction filtration to obtain crystals and a filtrate containing more light components. After the crystals were slowly melted, through molecular distillation, the conditions of molecular distillation were as follows: the evaporation temperature was 25°C, the evaporation pressure was 100Pa, and the feed rate was 4.0mL / min to obtain 44.2g of anethole. The purity of anethole was 97.1%. The rate is 44.2%.

Embodiment 2

[0023] Place the beaker containing 100g of fennel oil in a low-temperature environment of -10°C and freeze for 2 hours, quickly crush the frozen body to 20 mesh, and separate it by suction filtration to obtain crystals and a filtrate containing more light components. After the crystals were slowly melted, molecular distillation was carried out. The conditions of molecular distillation were as follows: the evaporation temperature was 30° C., the evaporation pressure was 2 Pa, and the feed rate was 1.6 mL / min. 59.5 g of anethole was obtained, and the purity of anethole was 99.5%. The yield was 59.5%.

Embodiment 3

[0025] Place the beaker containing 100g of fennel oil in a low-temperature environment of 0°C for 5 hours, and quickly crush the frozen body to 30 mesh, and separate it by suction filtration to obtain crystals and a filtrate containing more light components. After the crystals were slowly melted, molecular distillation was carried out. The conditions of molecular distillation were as follows: the evaporation temperature was 50° C., the evaporation pressure was 10 Pa, and the feed rate was 1.0 mL / min to obtain 60.9 g of anethole. The purity of anethole was 99.1%. The yield was 60.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com