Method for preparing rutile titanium dioxide from new process titanium slag

A rutile titanium dioxide and process technology, which is used in the removal of titanium dioxide, solid waste, titanium oxide/hydroxide, etc., can solve the problems of low acid hydrolysis rate, difficult crystal structure, quality limitation of titanium dioxide, etc., to reduce production. cost, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

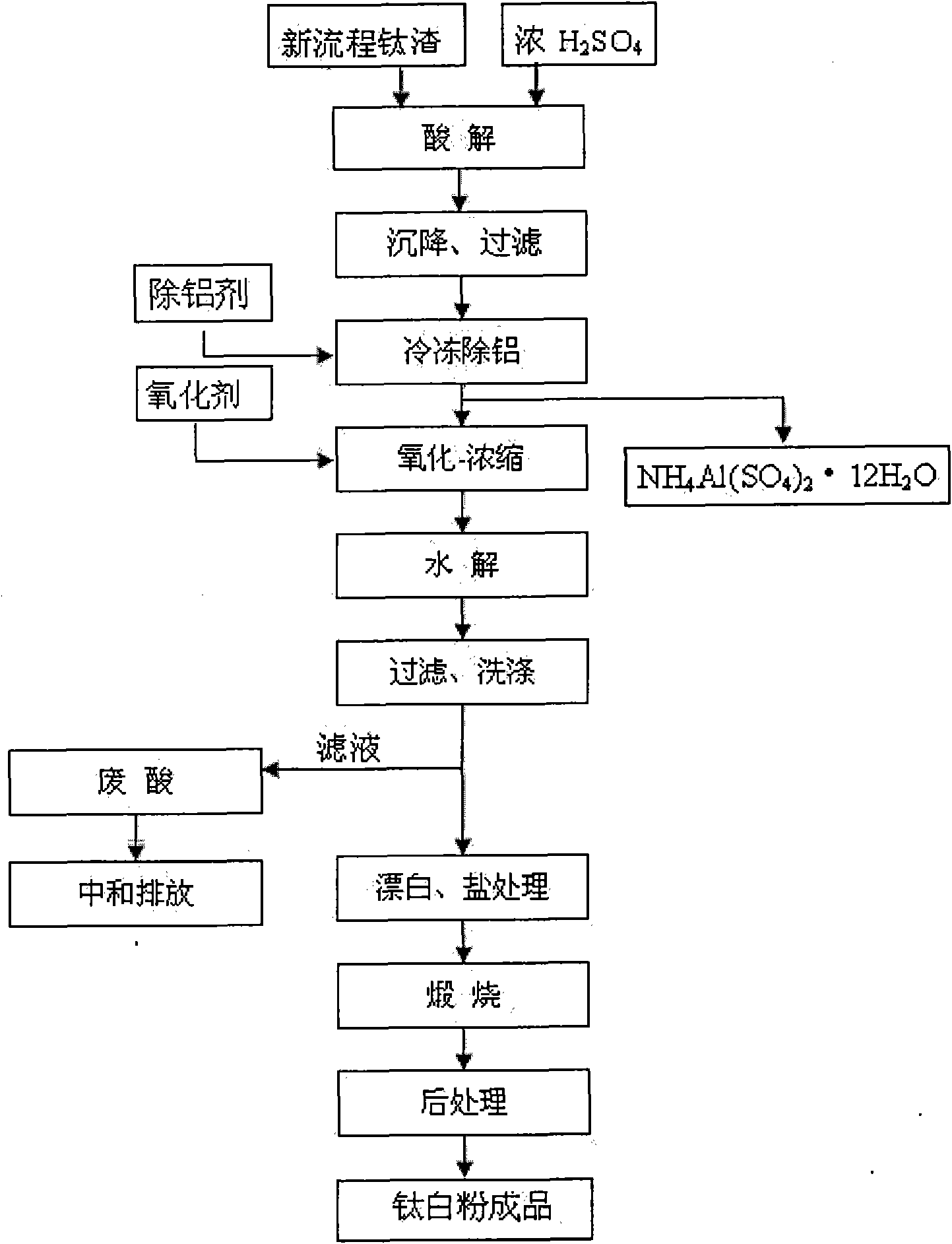

Method used

Image

Examples

Embodiment 1

[0052] Take 1000g of titanium slag of the new process that is crushed to a particle size greater than 45 microns and the particle ratio is less than 15% (see Table 2 for the composition), put 1683 grams of 98% concentrated sulfuric acid into a 5000mL beaker according to the acid ore mass ratio of 1.65, and then add it while stirring Titanium slag powder, then add 1 gram of Sb2O and mix evenly, add 35g of water to adjust the reaction acid concentration to 96%; then heat up while stirring, when the temperature rises to 150°C, stop heating, the reaction will proceed spontaneously, and finally form For the solid mixed phase, place it at 200°C for aging for 4 hours, add 2500mL of water for leaching, and maintain the leaching temperature at 70°C for 2 hours.

[0053] After the leaching is completed, add 2 grams of FeS first, then add 15 ppm flocculant formaldehyde dimethyl ammonium modified polyacrylamide (same as Comparative Example 1) for sedimentation, filter and separate to obtai...

Embodiment 2

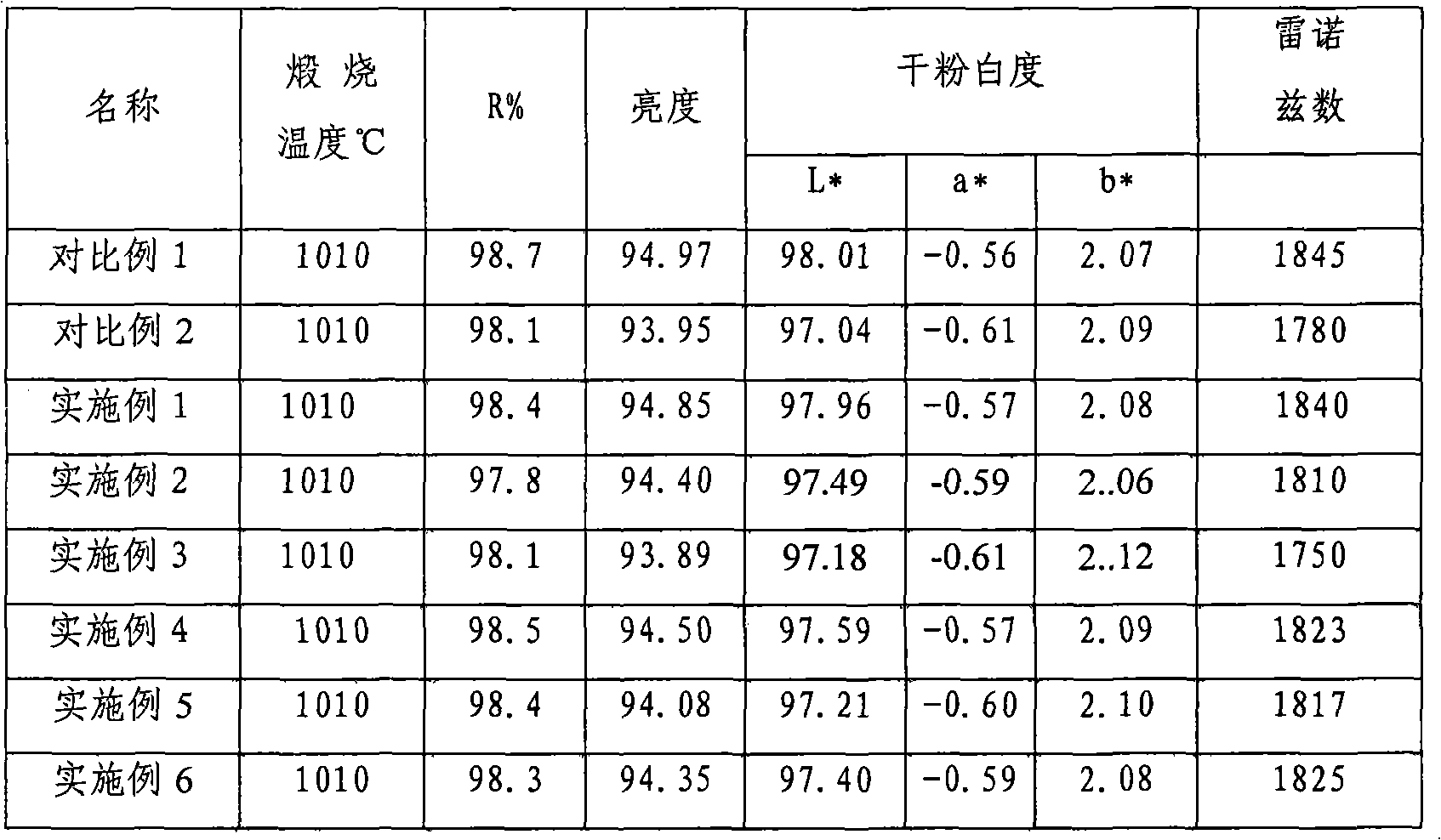

[0057] Get new process titanium slag powder 1000g (composition is shown in Table 2), other is with embodiment 1, prepares the rutile titanium dioxide finished product 490g of the various performances that quality reaches application requirements, and the yield of titanium dioxide in the new process titanium slag is 86%, Pigment properties are shown in attached table 3.

[0058] As can be seen from Table 3, for the present embodiment, the chromium, vanadium, and aluminum contents are higher than that of Example 1, which has a relatively large influence on the pigment performance of the product, and the resulting pigment performance is slightly worse than that of Example 1.

Embodiment 3

[0060] Get new flow process titanium slag powder 1000g (composition is shown in Table 2), other is with embodiment 1, prepares the rutile titanium dioxide finished product 510g of the various properties that quality reaches application requirements, and the yield of titanium dioxide in the new flow process titanium slag is 86%, Pigment properties are shown in attached table 3.

[0061] Find by table 3, to present embodiment, chromium, vanadium, aluminum content are higher than embodiment 2, bigger to the pigment performance influence of product, the pigment performance of gained is worse than embodiment 2, solid requires the chromium of new flow process titanium slag, The content of vanadium and aluminum impurities is as low as possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com