Method for manufacturing super strong steel body

一种制造方法、超高强度的技术,应用在制造工具、激光焊接设备、淬火装置等方向,能够解决变化量大、缺陷、产品损伤等问题,达到防止产品损伤或缺陷、减少后续处理工序、减少生产效率低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

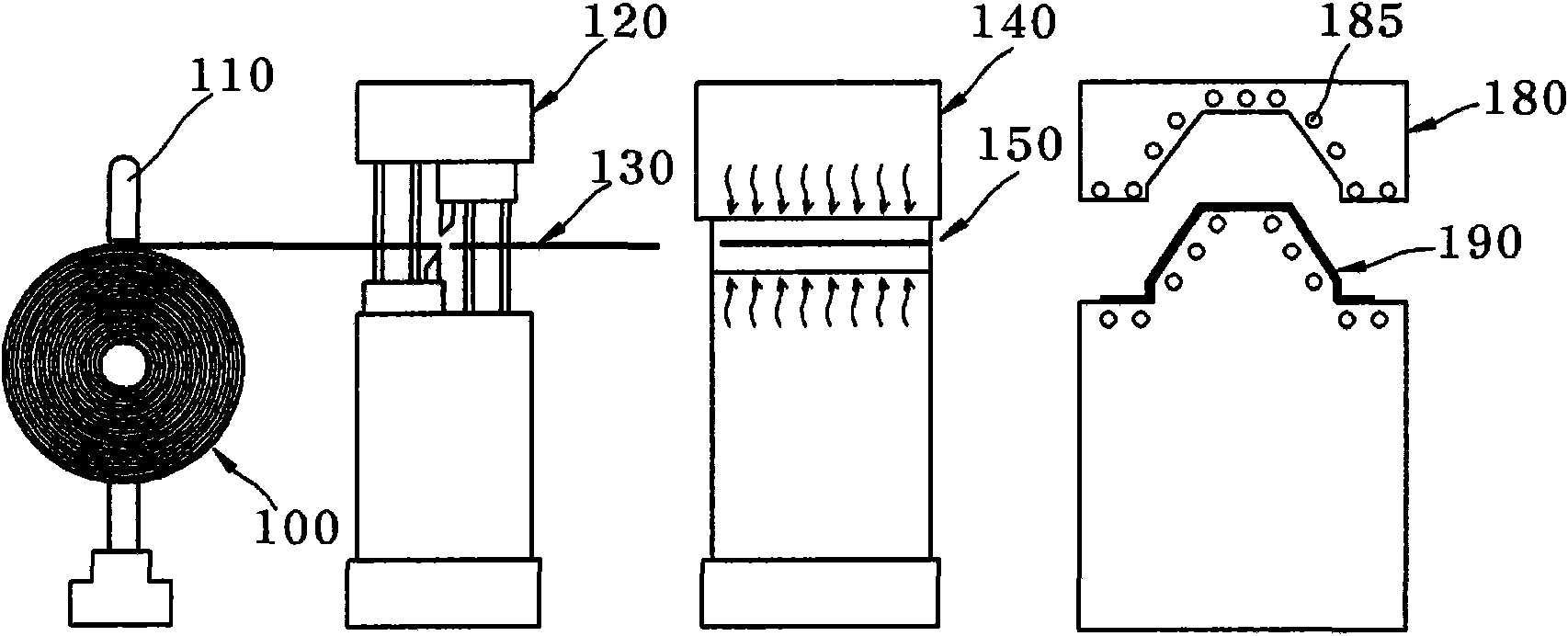

[0021] Hereinafter, the method for manufacturing a green steel body of the present invention will be described in detail with reference to the accompanying drawings.

[0022] In the process, in order to clearly and simply describe the above-mentioned manufacturing method, lines, thicknesses, and sizes of members in the drawings may be exaggerated.

[0023] In addition, the vocabulary described below is defined according to the functions of the present invention, so it may differ from the user's or operator's intention or practice.

[0024] Therefore, the understanding of these terms should be based on the contents of the entire specification.

[0025] Hereinafter, the method for manufacturing an ultra-high-strength green steel body and the green steel body manufactured by the method of the present invention will be described in detail with reference to the accompanying drawings.

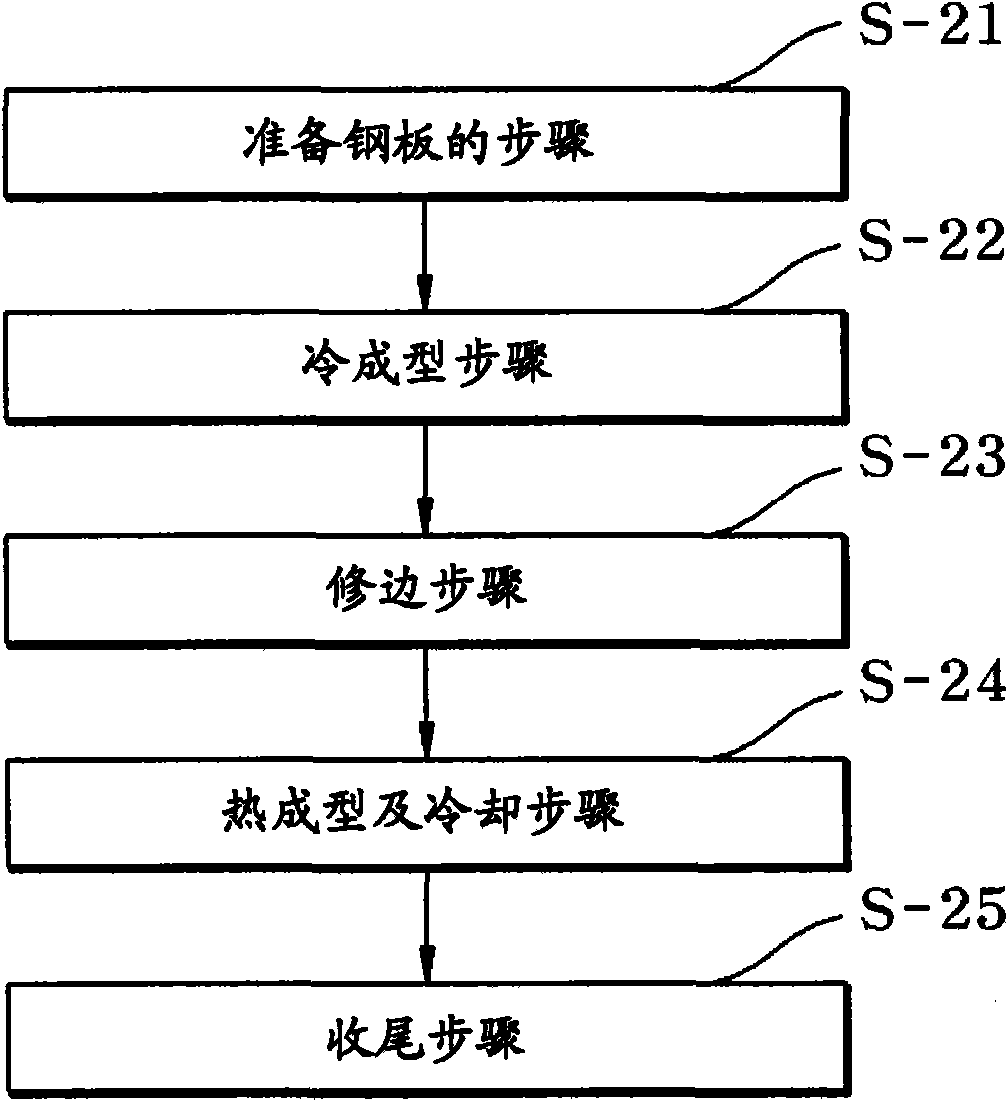

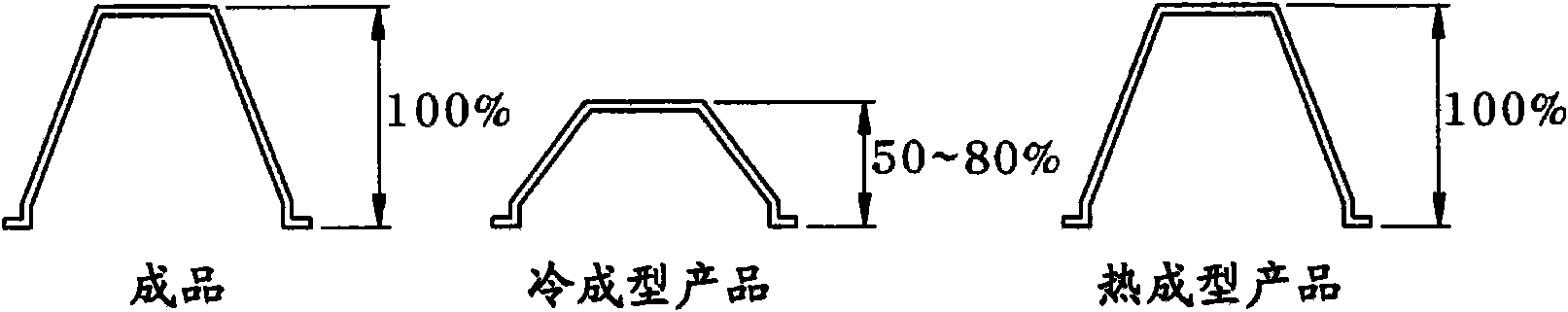

[0026] figure 2 It is a flow chart of the steel green body manufacturing method of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com