Subcooled oil cooler and novel economizer screw machine refrigeration cycle system

A circulating system and oil cooler technology, applied in subcoolers, refrigerators, refrigeration components, etc., can solve the problems of difficult cleaning of scale, fluctuations in oil temperature, etc., and achieve the effects of stable gas volume, avoiding vibration, and efficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

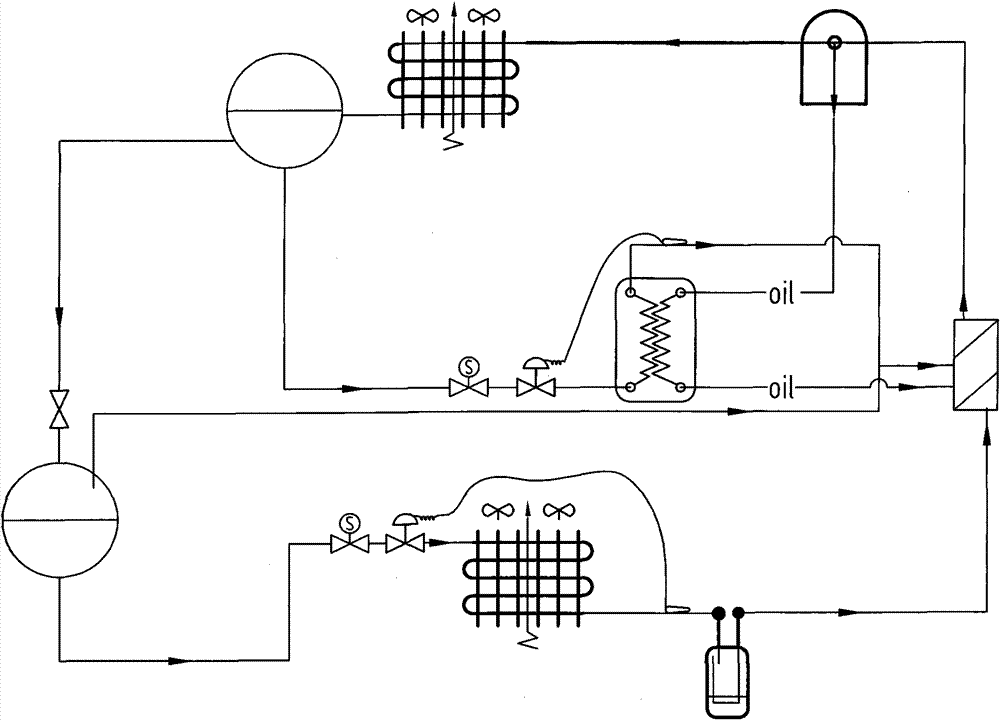

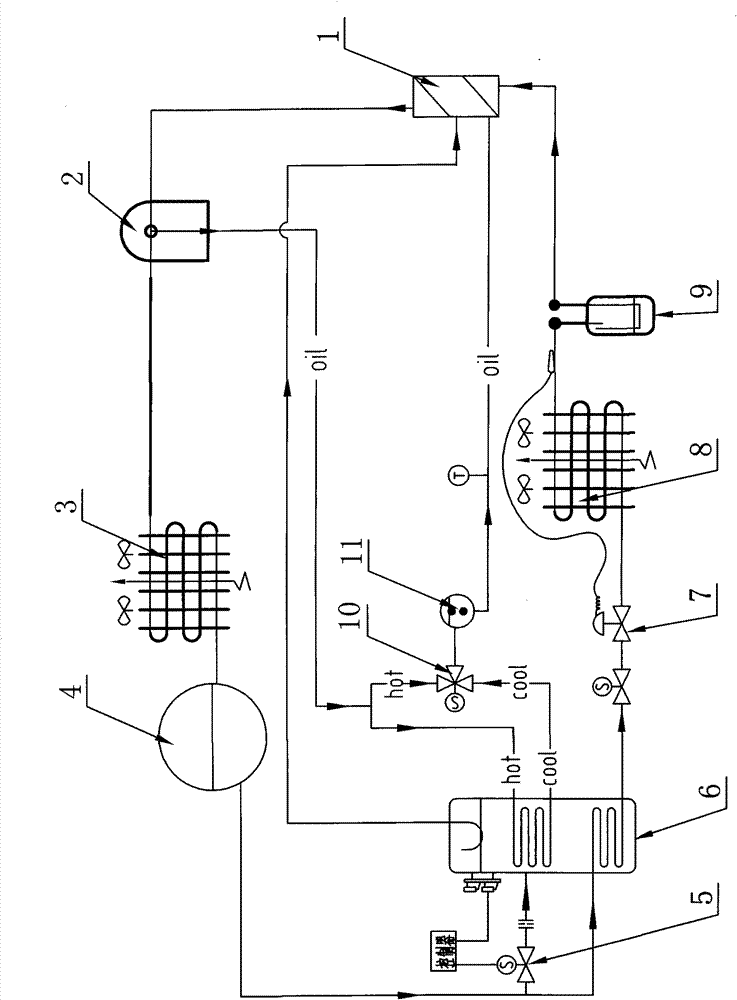

[0018] Embodiment 1: as image 3 Shown is a new economizer screw machine refrigeration cycle system using the above-mentioned subcooling oil cooler, which is characterized in that the exhaust gas from compressor 1 enters oil separator 2 to separate refrigerant gas and refrigerated oil, high temperature and high pressure refrigeration The agent gas enters the condenser 3 and is condensed into a liquid. The liquid in the condenser 3 enters the liquid receiver 4. The liquid outlet pipeline of the liquid receiver 4 is divided into two routes. The main route enters the supercooled oil cooler 6 and is supercooled. After being throttled by the throttle valve 7, the liquid enters the evaporator 8 to evaporate and absorb external heat, and the evaporated gas passes through the gas separator 9 to separate the mixed liquid and return to the compressor 1 to be compressed again; the attached liquid, when When the liquid in the container is at the lower limit, the controller controls the so...

Embodiment 2

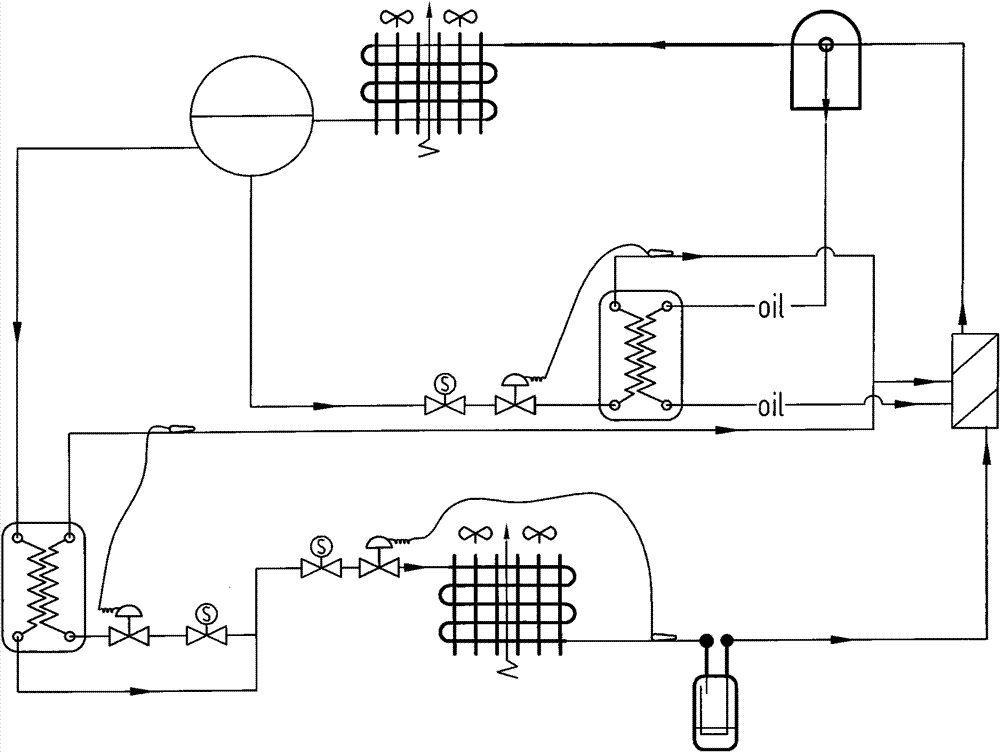

[0019] Embodiment 2: as Figure 4 Shown is a new economizer screw machine refrigeration cycle system using the above-mentioned subcooling oil cooler, which is characterized in that the exhaust gas from the compressor 1 enters the oil separator 2 to separate the refrigerant gas from the refrigerated oil, and the high-temperature and high-pressure refrigerant gas Entering the condenser 3 to be condensed into liquid, the liquid in the condenser 3 enters the liquid receiver 4, the liquid outlet pipeline of the liquid receiver 4 is divided into two routes, the main route enters the supercooled oil cooler 6 and is supercooled, and the supercooled After the liquid is throttled by the throttle valve 7, it enters the evaporator 8 to evaporate and absorb external heat. The evaporated gas passes through the gas separator 9, separates the mixed liquid, and returns to the compressor 1 to be compressed again; the attached liquid, when in the container When the liquid is at the lower limit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com