Thermoelectric effect based low energy consumption gas hydrate synthesizer

A gas hydrate and thermoelectric effect technology, applied in chemical/physical processes, pressure vessels used in chemical processes, chemical/physical/physicochemical processes, etc., can solve the problems of reducing hydrate efficiency and subcooling, and achieve Reduce cooling costs, reduce cooling costs, and improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

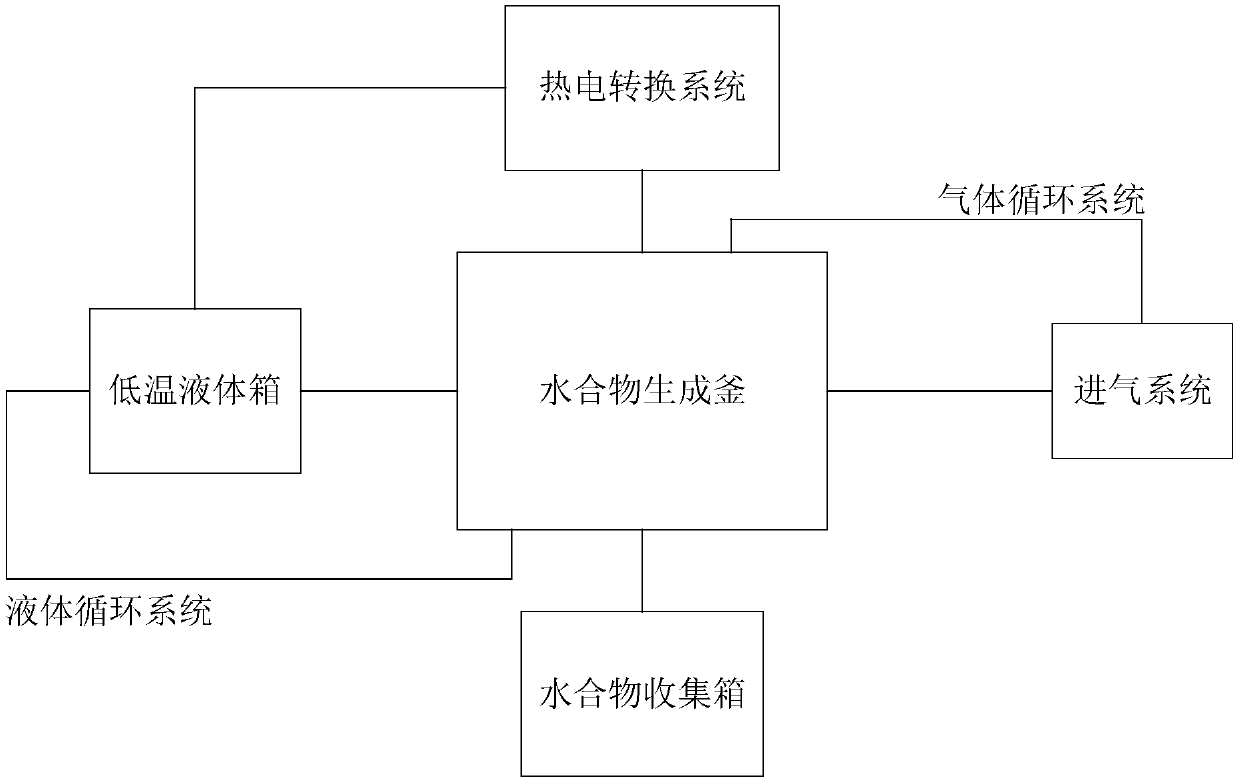

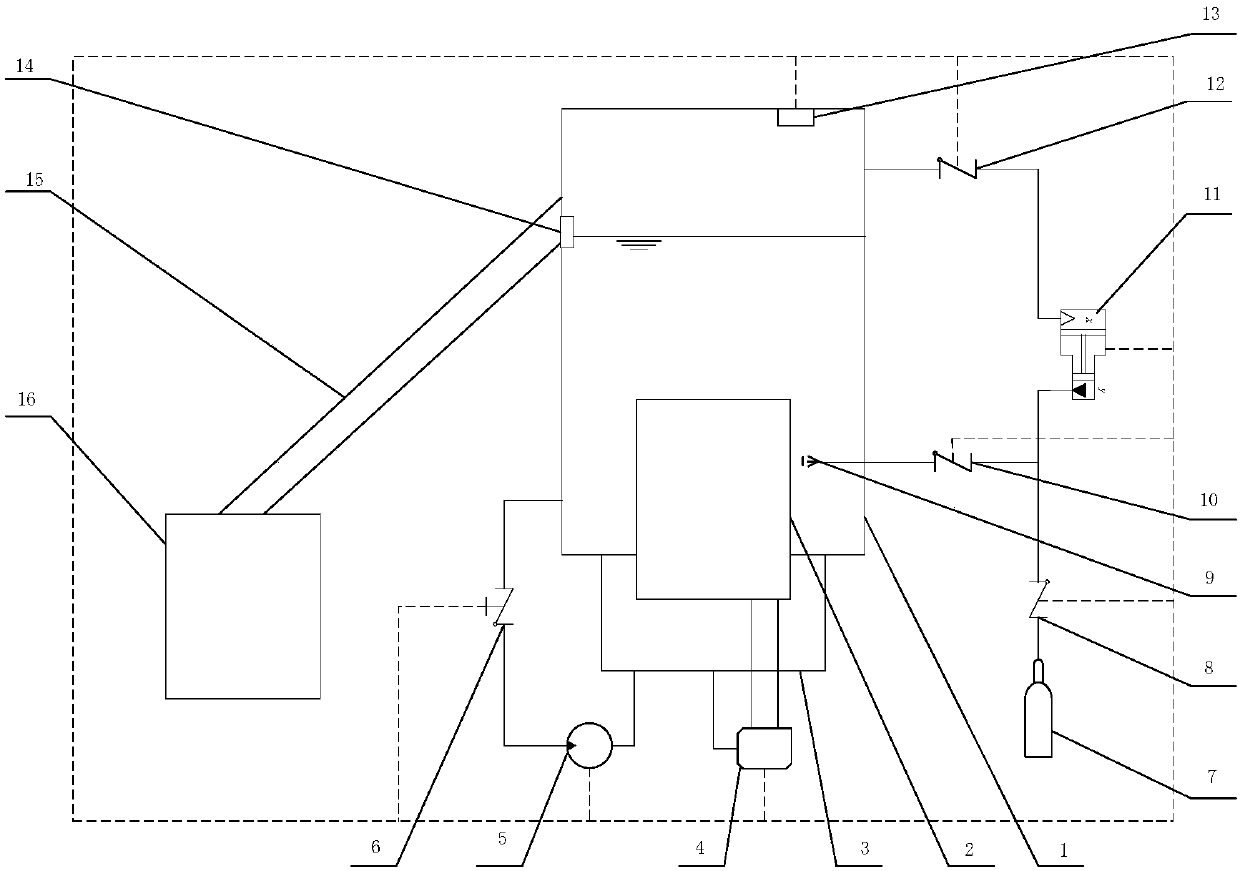

[0022] figure 1 Shown is the block diagram of the working principle of the low-energy gas hydrate synthesis device based on the thermoelectric effect. The working process is as follows: open the check valve b10, the high-pressure gas enters the hydrate synthesis tank 1 and the low-temperature liquid to form hydrate, and the thermoelectric module group in the process 2 absorbs heat and converts it into electrical energy, and drives the refrigeration device through the voltage stabilizer 4. After the hydrate is generated, it is suspended on the liquid surface, discharged from the hydrate output outlet, and enters the hydrate collection tank 16 through the transmission track 15 . When the liquid level is lower than the set value, the one-way valve a6 is opened, the water pump 5 is running, and liquid is supplied to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com