Fiber aggregate material formed by coating fine air pockets by microfibers and production process thereof

A production process, microfiber technology, applied in fiber processing, filament generation, climate sustainability, etc., can solve the problems of no sound absorption capacity, odor of rubber sheets, easy stickiness or falling off, etc., and achieve good compressibility , good bulkiness, good compression resistance and shape recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

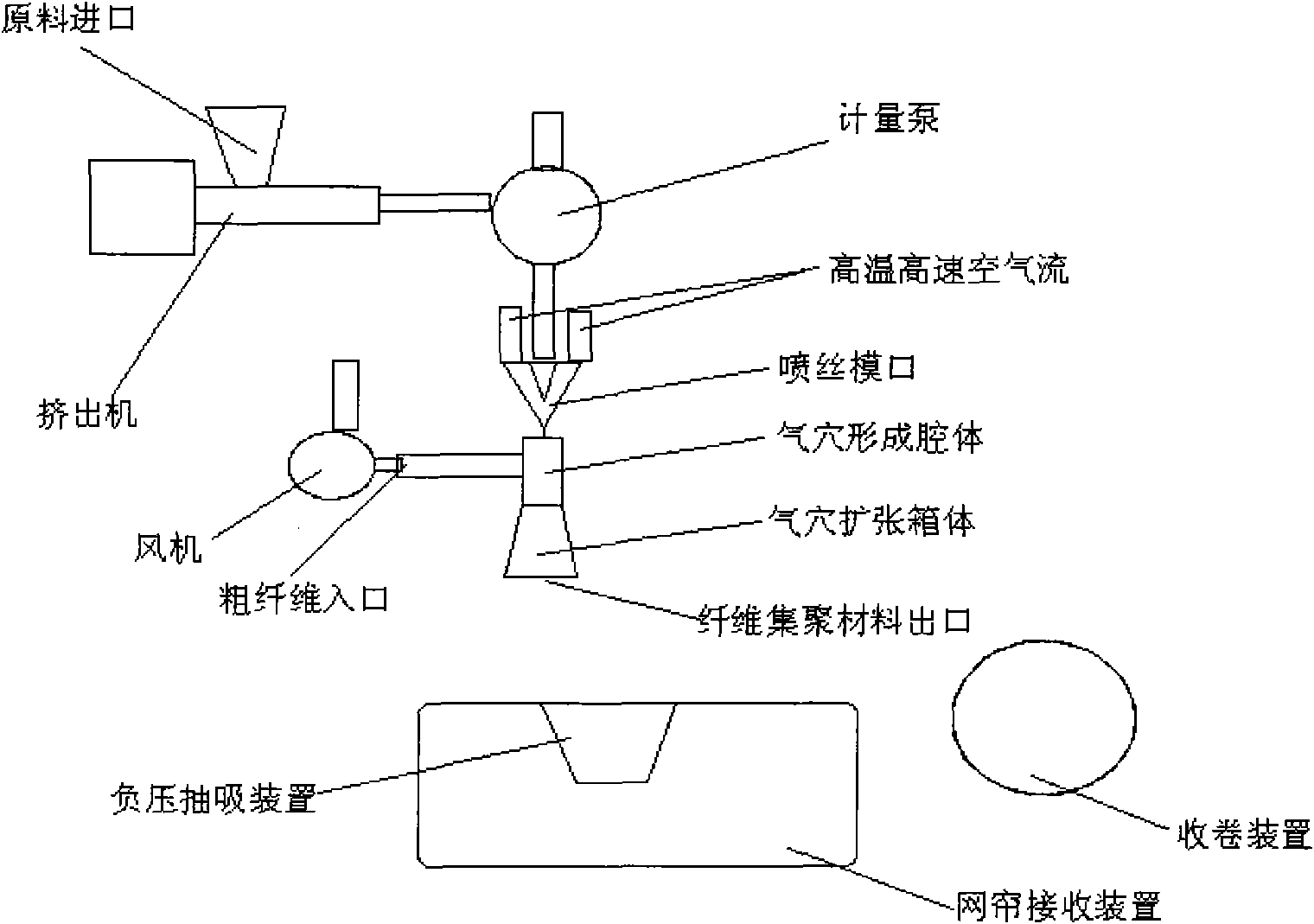

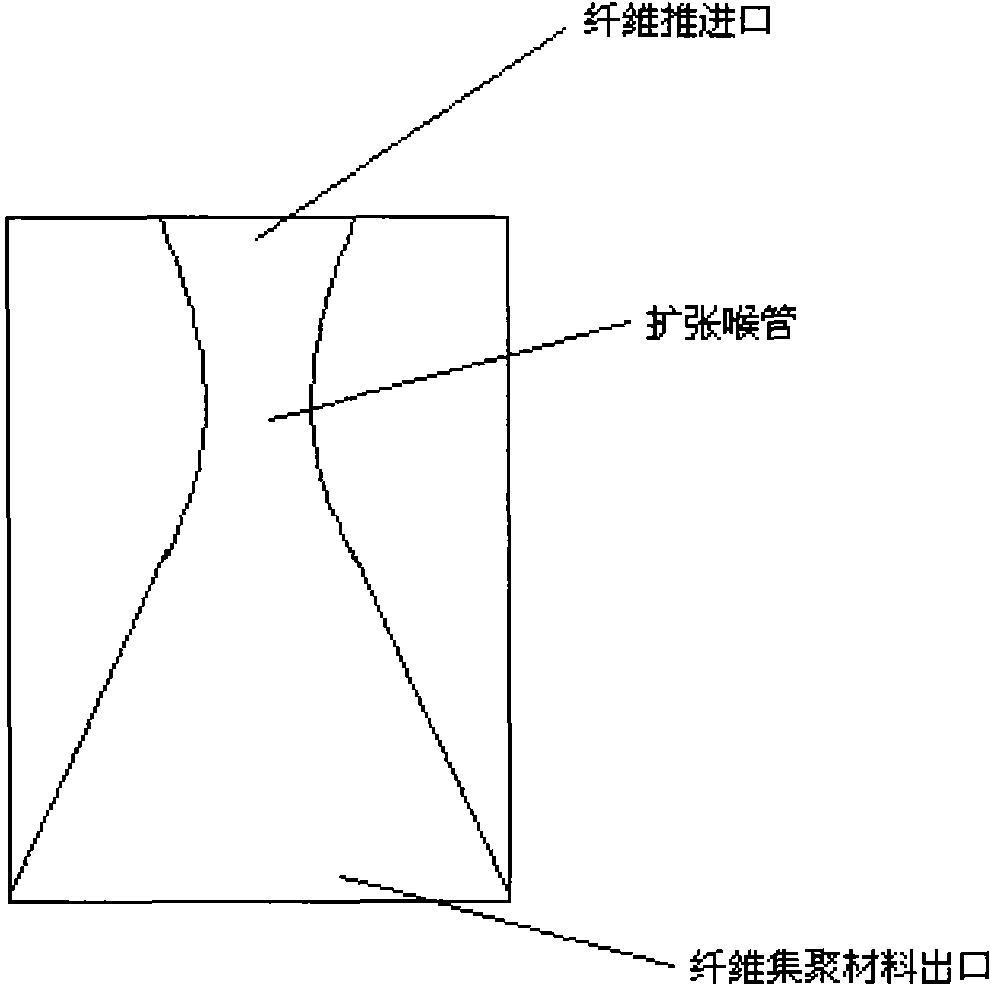

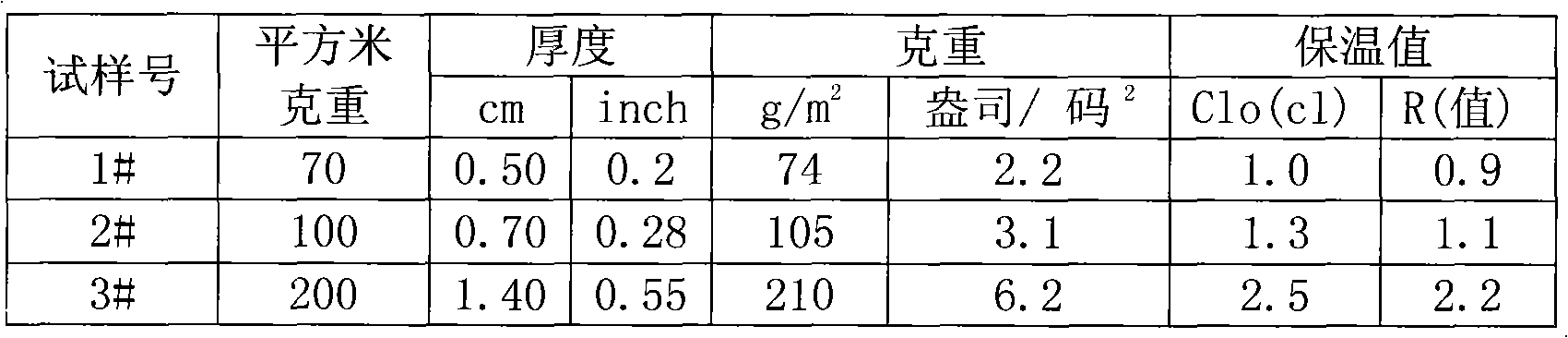

Embodiment 1

[0025] The polypropylene polymer particles are melted by the extruder and then extruded into the melt metering pump, and then transported to a spinning die through the melt metering pump. Stretch, get the microfibers. The fiber fineness is selected as an average diameter of 2 microns, and the spinneret die is set above an air cavity forming cavity, and the microfibers in a molten state quickly wrap the thick fiber in the cavity to form an air cavity. On one side of the cavitation forming cavity, a fan continuously sends the screened crude fibers into the cavity, and the crude fibers sent into the cavity are continuously wrapped by the molten microfibers ejected from the upper part. The thick polyester polyester fiber with the shape recovery memory function is selected, the average diameter of the fiber fineness is between 20 microns, and the length is 4 cm. The symbiosis of microfibers and thick fibers in the cavitation forming box enters the cavitation expansion box below th...

Embodiment 2

[0028] The polypropylene polymer particles are melted by the extruder and then extruded into the melt metering pump, and transported to a spinning die through the melt metering pump. The spinneret die opening is a spinneret hole with a linear arrangement in the transverse direction at an interval of 0.3 mm, and the diameter of the spinneret hole is selected as 0.25 mm. The transverse length of the spinneret die is greater than 100 cm. Both sides of the spinneret die are stretched by high-speed and high-temperature air flow to obtain microfibers. The fiber fineness is selected as an average diameter of 2 microns, and the spinneret die is set above an air cavity forming cavity, and the microfibers in a molten state quickly wrap the thick fiber in the cavity to form an air cavity. On one side of the cavitation forming cavity, a fan continuously sends the screened crude fibers into the cavity, and the crude fibers sent into the cavity are continuously wrapped by the molten microf...

Embodiment 3

[0033] The polypropylene polymer particles are melted by the extruder and then extruded into the melt metering pump, and transported to a spinning die through the melt metering pump. The spinneret die opening is a spinneret hole with a linear arrangement in the transverse direction at an interval of 0.3 mm, and the diameter of the spinneret hole is selected as 0.25 mm. The transverse length of the spinneret die is greater than 100 cm. Both sides of the spinneret die are stretched by high-speed and high-temperature air flow to obtain microfibers. The fiber fineness is selected as an average diameter of 2 microns, and the spinneret die is set above an air cavity forming cavity, and the microfibers in a molten state quickly wrap the thick fiber in the cavity to form an air cavity. On one side of the cavitation forming cavity, a fan continuously sends the screened crude fibers into the cavity, and the crude fibers sent into the cavity are continuously wrapped by the molten microf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com