Hot plate uniformly heating technique for use in solar cell assembly process

A solar cell and assembly process technology, applied in the direction of circuits, electrical components, laminating devices, etc., can solve the problems of difficult temperature convergence, poor temperature uniformity, and low equipment failure rate, and achieve easy replacement and maintenance, pumping High vacuum degree and uniform vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

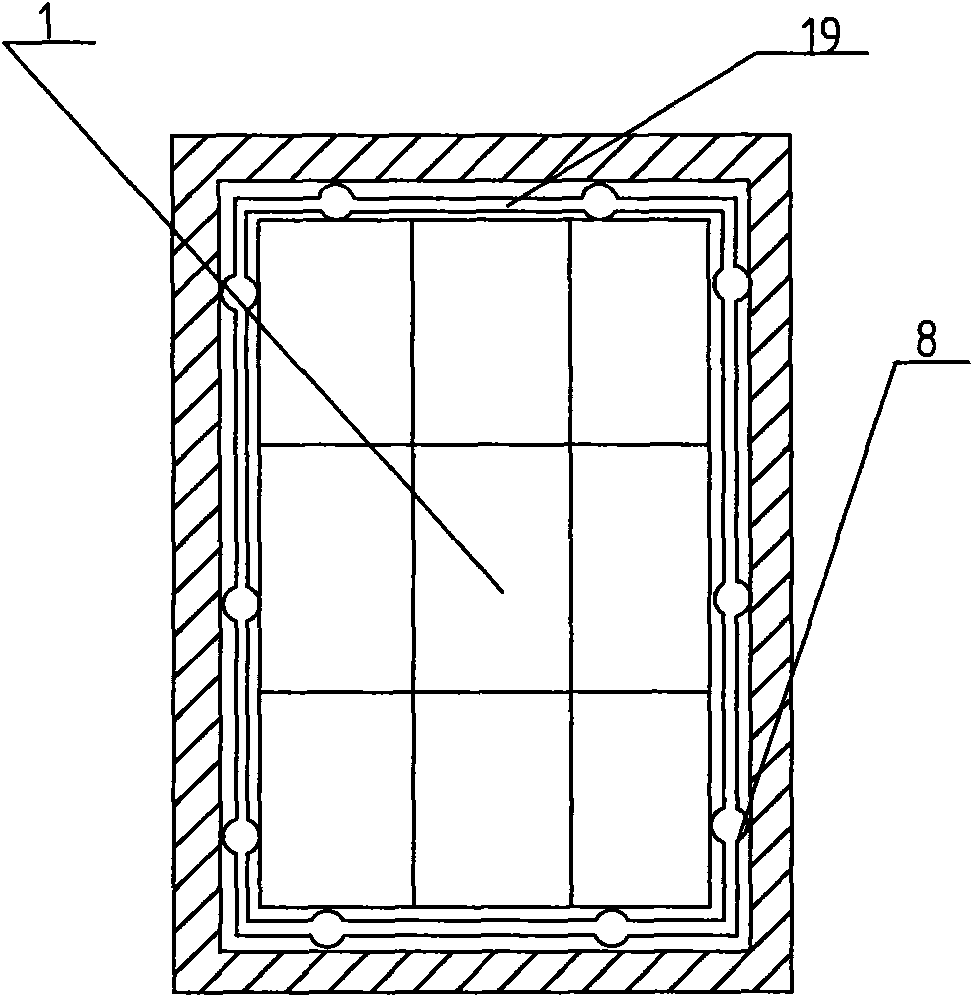

[0036] Such as Figure 1-3 Shown, a hot plate uniform heating technology in a solar cell assembly process includes the following steps:

[0037] ① Put the solar cell module to be packaged into the vacuum chamber 7 formed by the heating table 1 and the upper cover 2 in the solar cell module laminator, and then seal the vacuum chamber 7;

[0038] ② Vacuumize the vacuum chamber 7;

[0039] ③ After the vacuuming is completed, close the vacuum valve, and heat and pressurize the solar cell module placed in the vacuum chamber 7 under a vacuum environment; The process of measuring the temperature at the temperature control point inside and performing thermal compensation according to the feedback result.

[0040] A laminator suitable for the uniform heating technology of a hot plate in a solar cell assembly process, including a heating table 1 and an upper cover 2, the upper cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com