Glass fiber flame retardant silica gel cloth and preparation method thereof

A technology of glass fiber cloth and glass fiber, which is applied in the field of glued glass fiber products, can solve the problems such as the lack of reference significance of the technology, and achieve the effects of less demanding process and equipment requirements, short process steps, and excellent longitudinal and transverse tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

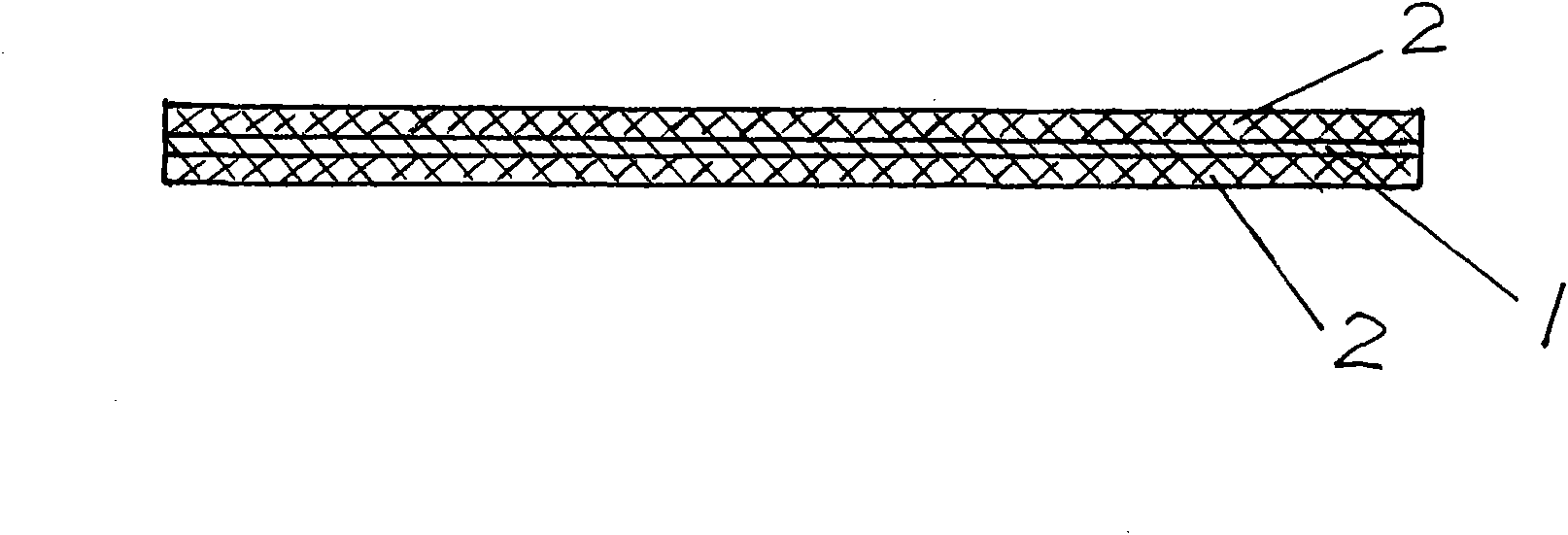

[0029] please see figure 1 , this example is based on manufacturing figure 1 The glass fiber flame retardant silicone cloth with the structure shown is taken as an example.

[0030] A) glass fiber cloth is dewaxed, and the commercially available fabric organization is plain weave and the grammage is 2500g / m 2 Glass fiber cloth, that is, non-alkali glass fiber cloth, is introduced from the entrance of the oven (also called dewaxing oven) in a continuous manner and drawn out from the oven outlet and rolled up. The temperature of the oven is controlled at 250 ° C, and the travel speed of the glass fiber cloth is controlled. 8m / min, the paraffin-type surface treatment agent contained in the glass fiber cloth is melted to become exposed inorganic glass fibers, and the dewaxed glass fiber cloth is obtained for use;

[0031] B) Prepare mixed rubber, put 1 part of raw rubber, 0.3 part of white carbon black and 0.5 part of hydroxy silicone oil into the mixing device acted by a kneade...

Embodiment 2

[0039] Only change the fabric structure of the fiberglass cloth in step A) from plain weave to twill weave and change the grammage to 1200g / m 2 , the oven temperature was changed to 345°C, and the travel speed of the glass fiber cloth was changed to 25m / min;

[0040] Change the parts by weight of the white carbon black used to prepare the rubber mix in step B) to 1.8 parts and change the parts by weight of hydroxy silicone oil to 0.3 parts, and change the temperature, that is, the kneading temperature, to 10°C;

[0041] Only change the mixing silicone rubber in step C) to 70 parts, use the combination of 20 parts of aluminum hydroxide and 10 parts of magnesium hydroxide as the flame retardant, use iron oxide yellow as the colorant, and the parts by weight are 5 parts, Vulcanizing agent is changed to the vulcanizing agent double 24 (curing agent double two four) of 0.45 parts by weight;

[0042] Only change the solvent in step D) to toluene that is 1 part by weight, the stirri...

Embodiment 3

[0047] please see figure 2 , this example is based on manufacturing figure 2 The glass fiber flame retardant silicone cloth with the structure shown is taken as an example.

[0048] A) Glass fiber cloth is dewaxed, will be by commercially available and fabric weave is satin weave and grammage is 400g / m 2 Glass fiber cloth, that is, non-alkali glass fiber cloth is introduced from the entrance of the oven (also called dewaxing box) in a continuous manner and drawn out from the outlet of the oven and rolled up. The temperature of the oven is controlled at 300 ° C, and the travel speed of the glass fiber cloth is controlled. 15m / min, the paraffin-type surface treatment agent contained in the glass fiber cloth is melted away to become exposed inorganic glass fiber, and the dewaxed glass fiber cloth is obtained for use;

[0049] B) To prepare the mixed rubber, put 1 part of raw rubber, 1 part of white carbon black and 0.2 part of hydroxy silicone oil into the mixing device acted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com