System and method for preparing alkaline water used for preparing flocculating agent

A technology for preparing system and flocculant, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high outsourcing cost, increase energy consumption, increase power consumption, etc., to improve the safety of production and operation, reduce kinetic energy consumption, The effect of small conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

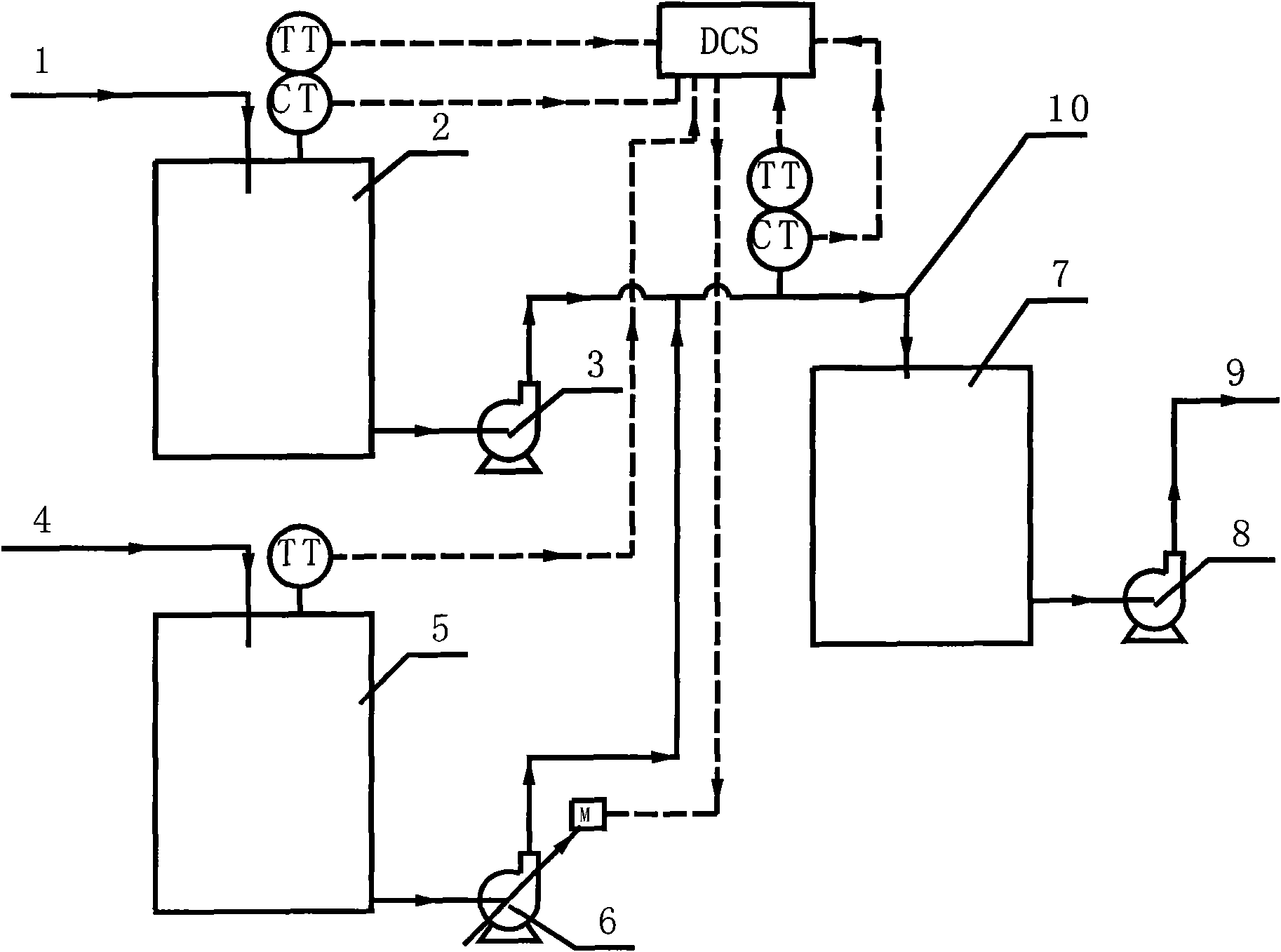

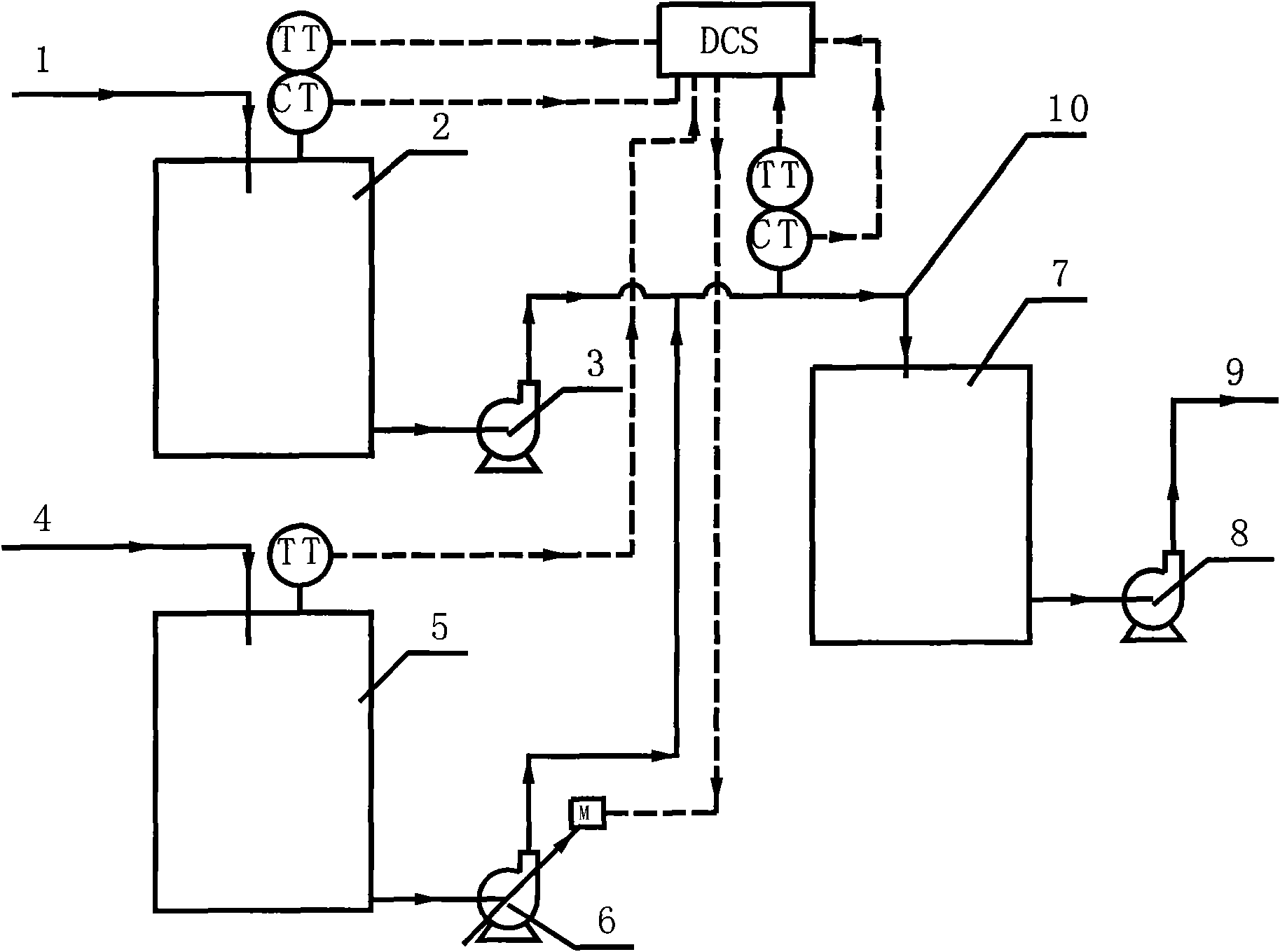

[0023] Such as figure 1 As shown, a preparation system for alkaline water required for the preparation of flocculants in the present invention is composed of the following structure: red mud washing liquid tank 2, red mud washing liquid tank 2 is connected to qualified alkaline water tank 7 through a combined pipeline 10; fresh water The storage tank 5 and the new water storage tank 5 are connected to the combined pipeline 10 through pipelines, the red mud washing liquid pump 3 is provided at the outlet of the red mud washing liquid tank 2, and the water pump 6 is provided at the outlet of the new water storage tank 5, and the red mud washing liquid Liquid tank 2 is provided with temperature detector 11 and caustic alkali concentration measuring instrument 12, is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com