Epoxy resin fracturing propping agent and preparation method thereof

A technology of fracturing proppant and epoxy resin, which is applied in the direction of chemical instruments and methods, earthwork drilling, mining fluids, etc. It can solve the problems of high design cost and high production cost, and achieve strong crush resistance, small conveying resistance, The effect of broad application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 8

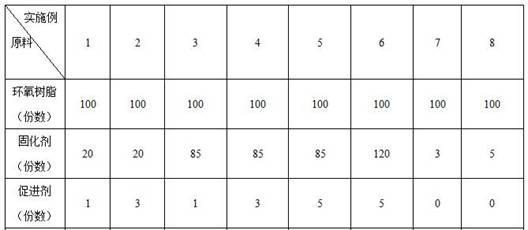

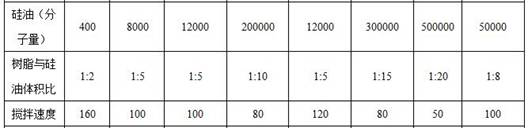

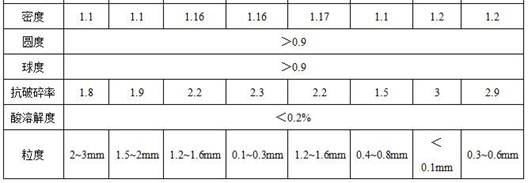

[0038] Examples 1 to 8 are eight implementations of the epoxy resin fracturing proppant of the present invention, and their corresponding product indicators.

[0039] As shown in Table 1 below:

[0040]

[0041]

[0042]

Embodiment 9

[0044] This embodiment discloses a preparation method of epoxy resin fracturing proppant.

[0045] Mix the epoxy resin, curing agent and accelerator according to the ratio of parts by weight of 100:100:5; mix until uniform to obtain a dispersed phase.

[0046] Among them, bisphenol A type epoxy resin E-51 is selected as the epoxy resin; the combination of imidazole and acid anhydride is selected as the curing agent; DMP-30 is selected as the accelerator.

[0047]Choose a silicone oil with a molecular weight of 470. Add the dispersed phase to the silicone oil for stirring, the ratio of the dispersed phase to the silicone oil is 1:5, control the stirring speed to 200 r / min, 250 r / min, or 300 r / min; after the dispersion is uniform, raise the temperature to 130-160 ℃, curing. An epoxy resin fracturing proppant with a particle size of 0.4-3.7 mm was obtained.

Embodiment 10

[0049] This embodiment discloses a preparation method of epoxy resin fracturing proppant.

[0050] Mix the epoxy resin, curing agent and accelerator according to the ratio of parts by weight of 100:100:5; mix until uniform to obtain a dispersed phase.

[0051] Among them, the epoxy resin is selected from the combination of bisphenol A epoxy resin E-44 and bisphenol A epoxy resin E-20; the curing agent is selected from dicyandiamide; the accelerator is selected from phenyldimethylurea and 2,4 toluene Combination of bisdimethylurea.

[0052] Choose a silicone oil with a molecular weight of 1000. Add the dispersed phase to the silicone oil for stirring, the ratio of the dispersed phase to the silicone oil is 1:10, control the stirring speed to 100 r / min, 150 r / min, or 200 r / min; after the dispersion is uniform, raise the temperature to 130-160 ℃, curing. An epoxy resin fracturing proppant with a particle size of 0.3-2.3 mm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com