Steel for fracture split connecting rods

A cracking connecting rod, quality technology, applied in the steel field of connecting rod"), can solve problems such as poor machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0074] The steel with the chemical composition shown in Table 1 was melted according to the usual smelting method, after casting and slabbing, rolling was carried out at a starting temperature of 1050°C and an ending temperature of 900°C to obtain bar steel.

[0075] The properties of the obtained bar steel were investigated as follows.

[0076] (1) Sulfide-based inclusions

[0077] In the longitudinal section at the position D / 4 (D is the diameter) from the surface of the bar steel, observe with an optical microscope (1000 times) 1mm 2 In the field of view, count the number of sulfide-based inclusions with a width of 1 μm or more. In addition, the aspect ratio of the sulfide-based inclusions having a width of 1 μm or more was measured, and the arithmetic mean thereof was obtained.

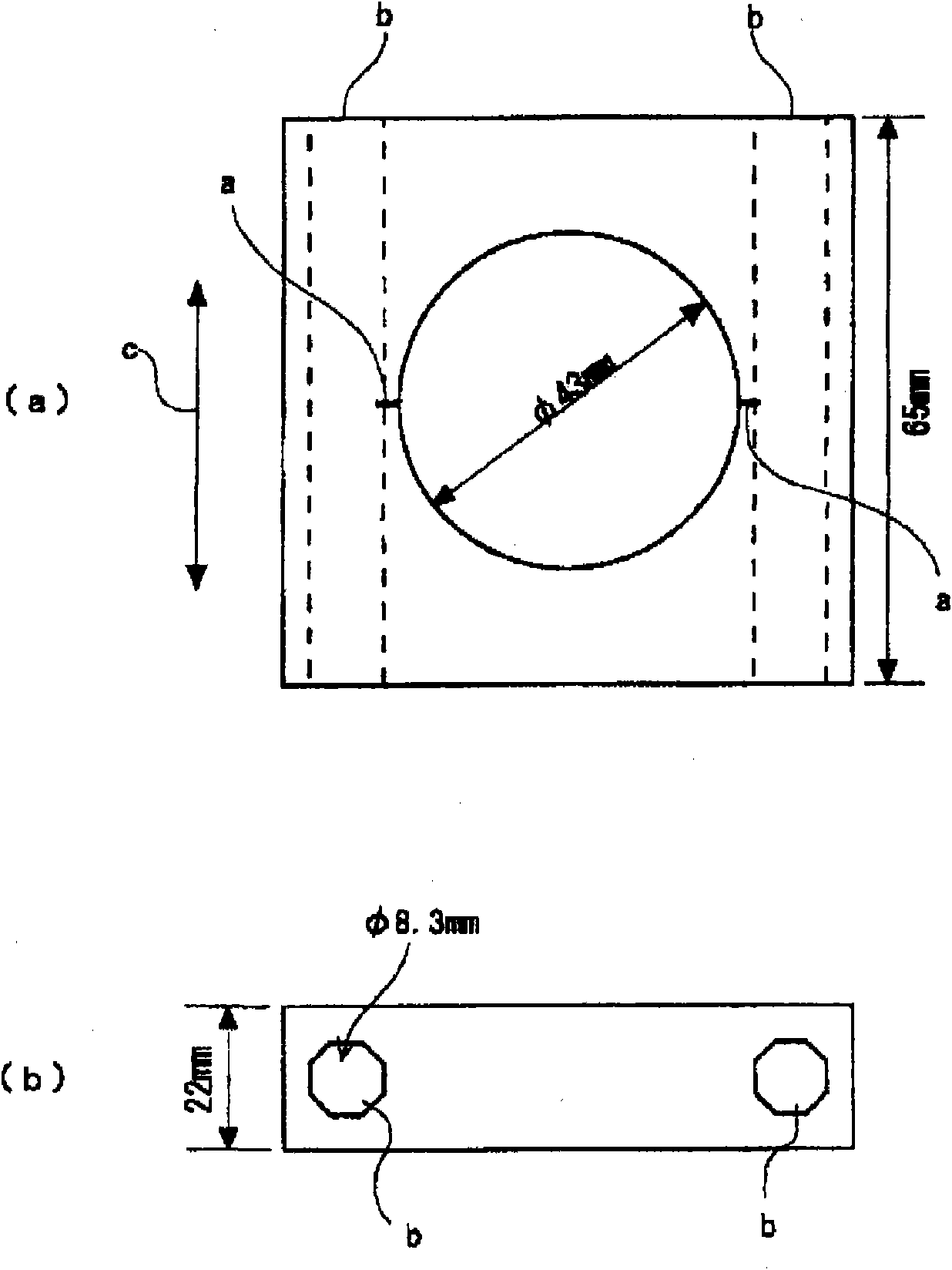

[0078] (2) Disintegration (dimension change)

[0079] The rods obtained in the experimental example were cut into appropriate lengths, heated to a temperature of 1200° C., flat-pressed to a t...

experiment example 2

[0097] Except using the steel of the chemical composition shown in Table 2, 3, it was the same as Experimental Example 2. Regarding the tool life, in each of the groups B to H and J, the tool life of the steel type to which no Ti was added was set as 1, and the tool life was expressed as a relative value at this time.

[0098] The results are shown in Tables 4-7. In addition, in Table 7, the tool life of steel type A1 when the tool life of steel type J1 is taken as 1 is also shown together, so that it can be compared with the tool life of group A which contains a large amount of V at about 0.160%. .

[0099] [Table 2]

[0100]

[0101] ※Al: less than 0.01% is an unavoidable amount, marked as "-"

[0102] [table 3]

[0103]

[0104] ※Al: less than 0.01% is an unavoidable amount, marked as "-"

[0105] [Table 4]

[0106]

[0107] [table 5]

[0108]

[0109] [Table 6]

[0110]

[0111] [Table 7]

[0112]

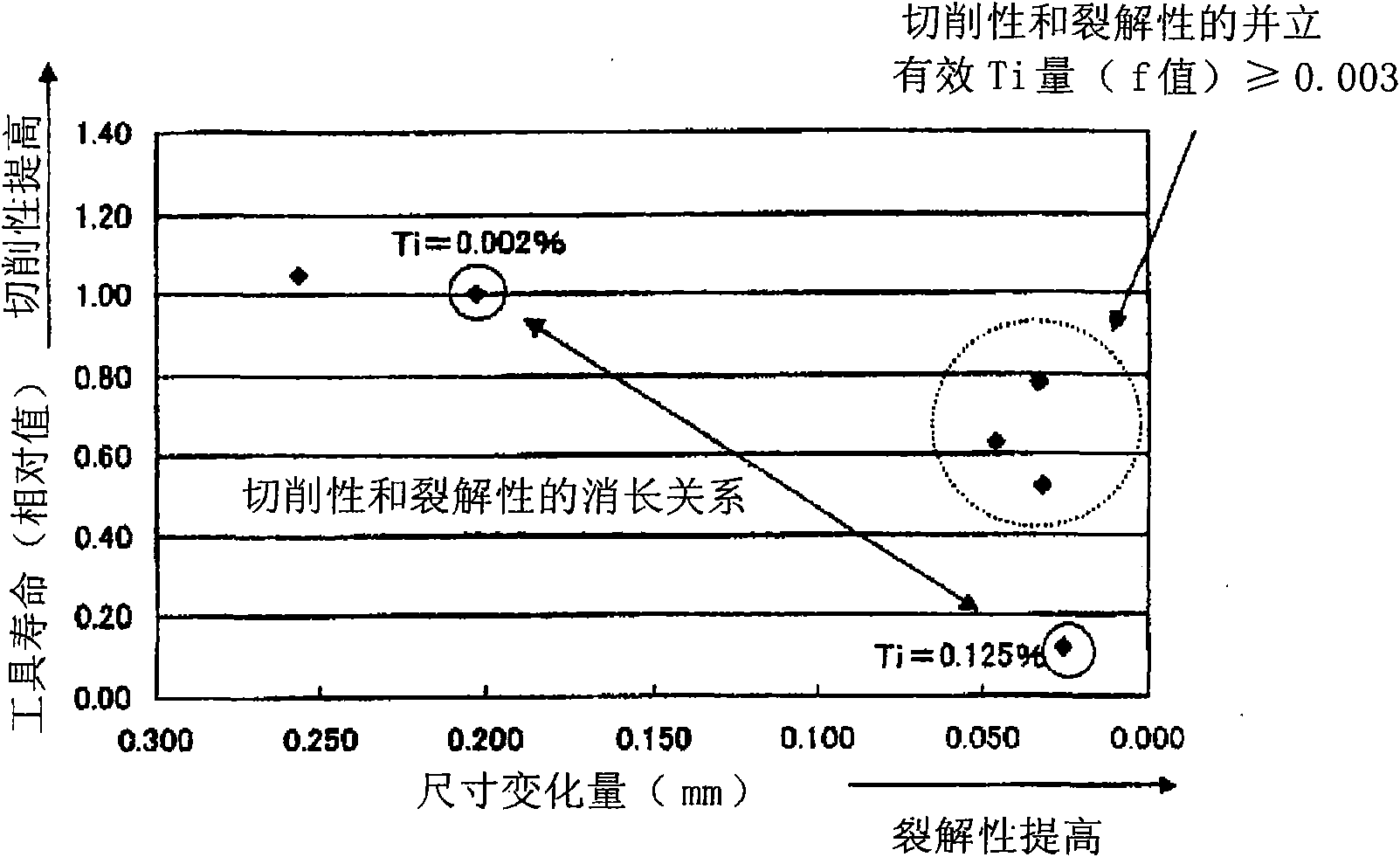

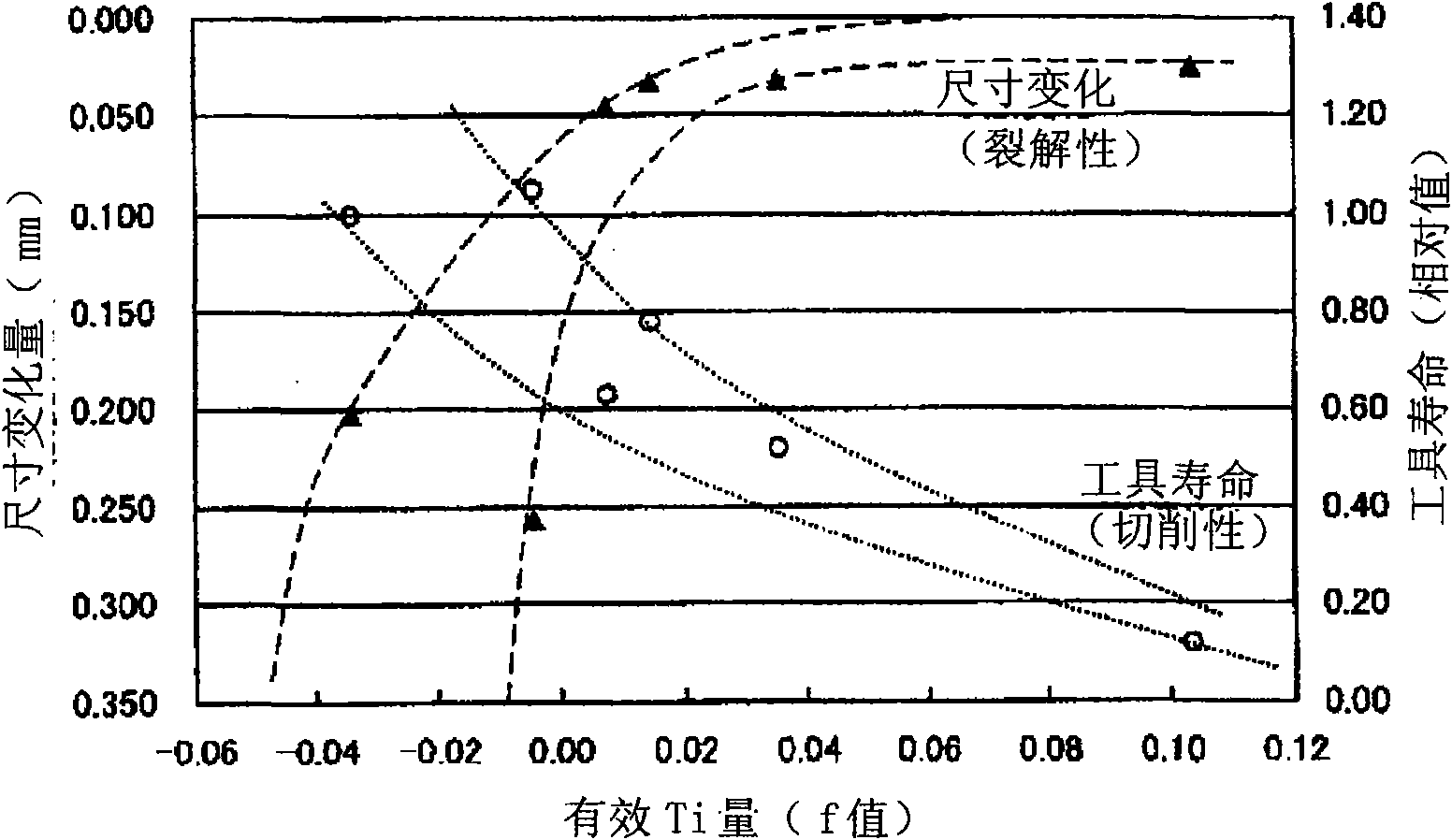

[0113] The size after cracking of steel types B...

experiment example 3

[0115] The steel type H2 shown in Table 2 was used, and the rolling start temperature and the rolling end temperature were as shown in Table 8 below, except that it was the same as Experimental Example 1.

[0116] The results are shown in Table 8

[0117] [Table 8]

[0118]

[0119] As can be seen from Table 8, the higher the rolling start temperature and the rolling finish temperature, the smaller the aspect ratio of the sulfide-based inclusions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com