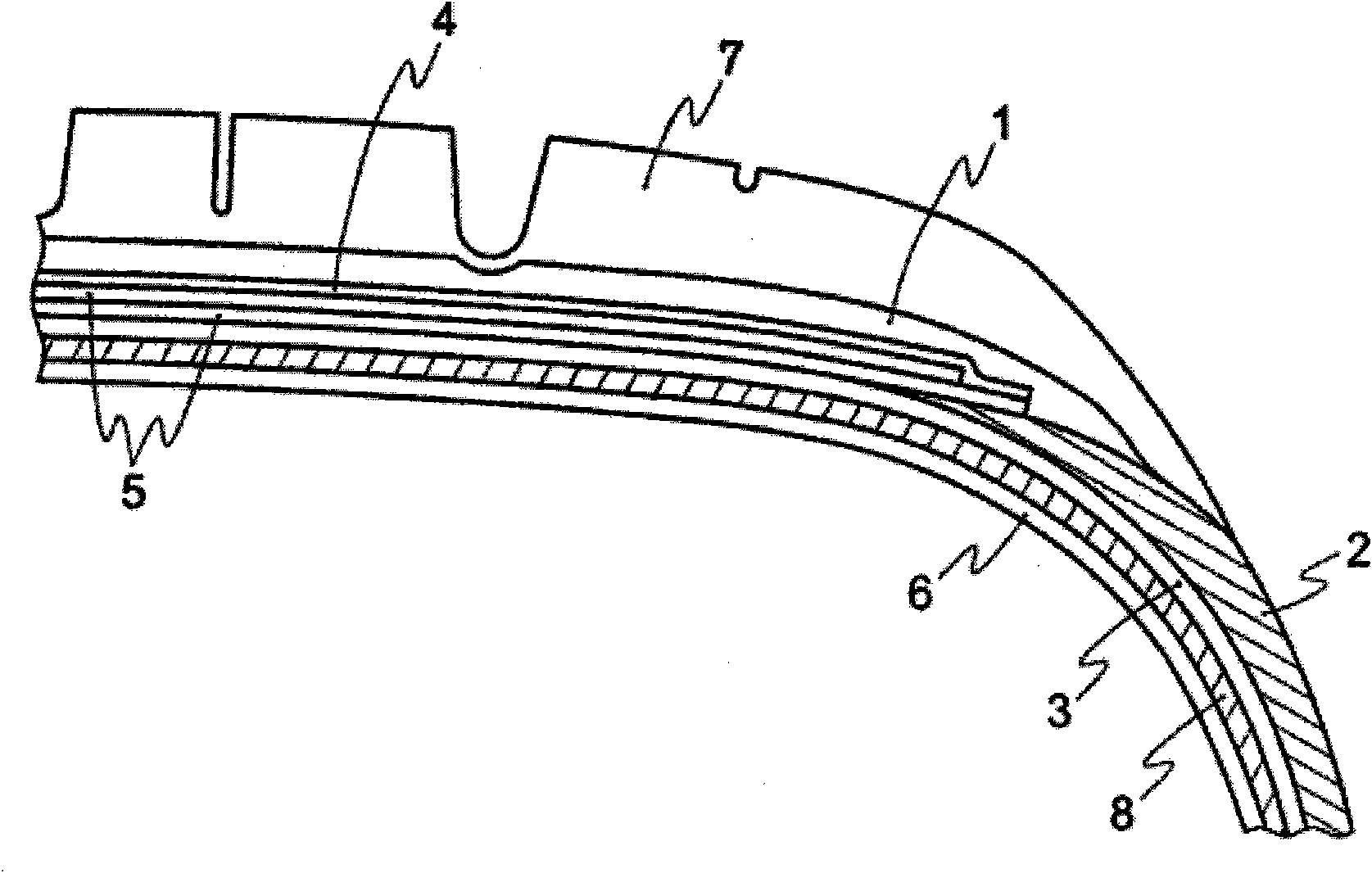

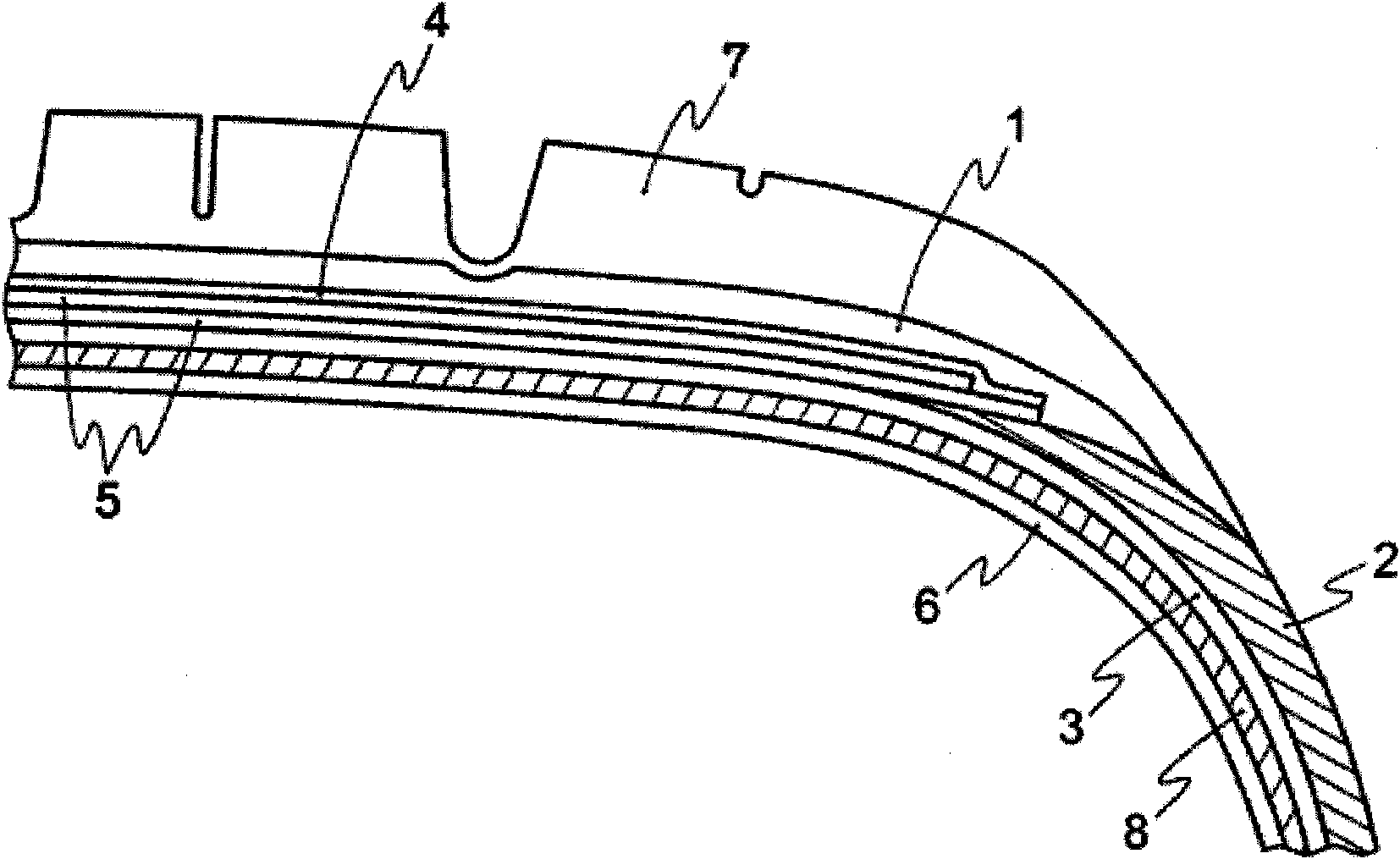

Rubber composition for tire

A rubber composition and rubber technology, applied in special tires, tire parts, tire edges, etc., can solve the problems of vulcanization reversion, E* reduction, tanδ increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~32 and comparative example 1~22

[0189]Tables 1 and 2 show the preferred blends as sidewall and barrier. Mix according to the mixing formula shown in Table 1 and Table 2 and commonly used medicines: relative to the diene rubber component of 100 parts by mass, mix 2.0 parts by mass of stearic acid, 3.0 parts by mass of zinc oxide, 3.0 parts by mass of antioxidant 6C, 5.0 parts by mass of aromatic oil, 1.0 parts by mass of wax; then use the Benbury internal mixer to mix the medicines except TACKROL V200 vulcanization accelerator auxiliary agent, insoluble sulfur and vulcanization accelerator TBBS shown in table 1 and 2, to obtain the mixture Refining. Next, using an open mill, TACKROL V200 vulcanization acceleration auxiliary agent, insoluble sulfur, and vulcanization accelerator TBBS were added to the obtained kneaded product, and kneaded to obtain an unvulcanized rubber composition. Under the condition of 170° C., the obtained unvulcanized rubber composition was vulcanized for 12 minutes, and the vulcanized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com