Oil-gas separator

A technology of oil-gas separator and air outlet pipe, which is applied in the direction of refrigeration components, refrigerators, lighting and heating equipment, etc. It can solve the problems of low assembly efficiency, troublesome manufacturing, troublesome assembly, etc., achieve high assembly efficiency, reduce overall cost, Produce simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

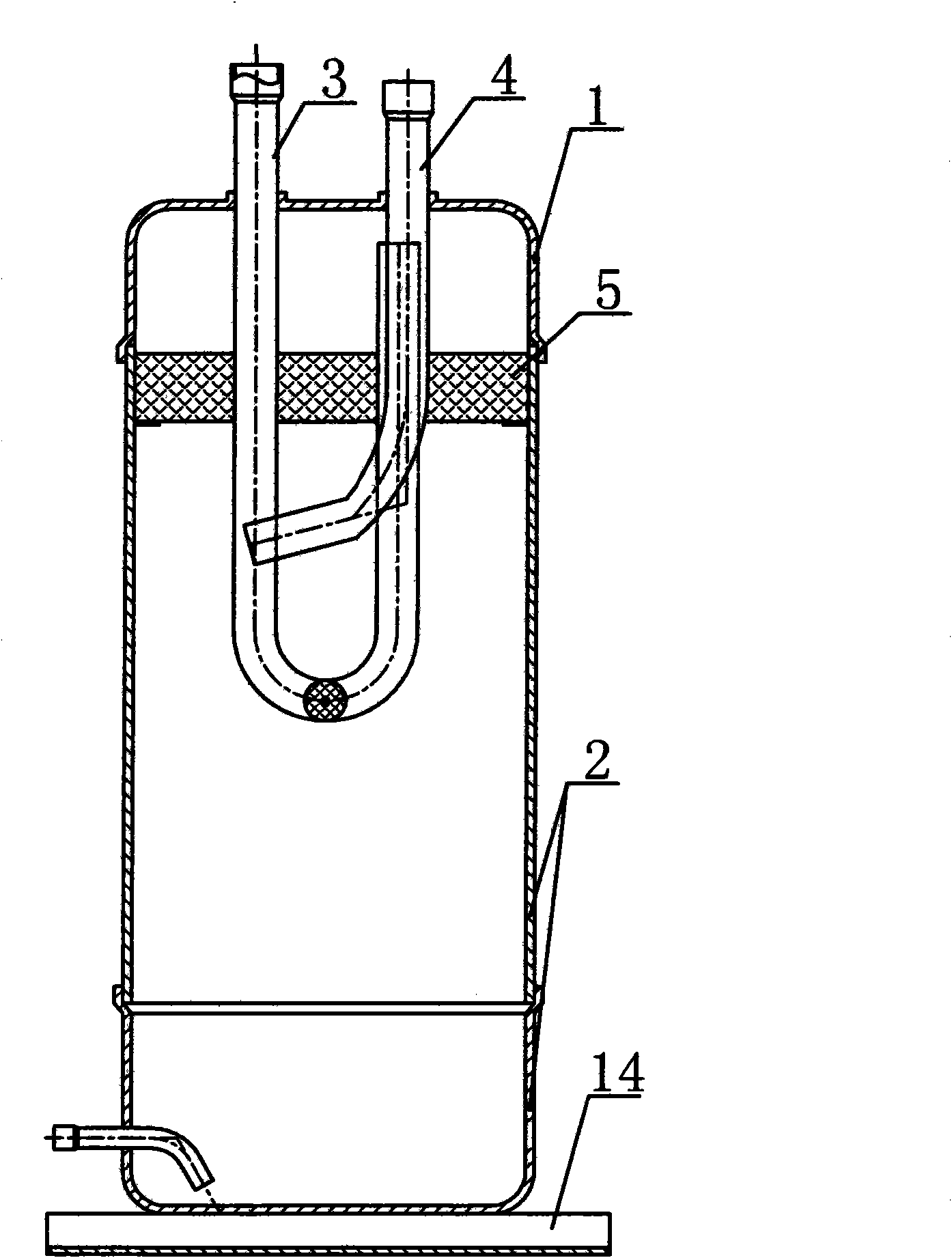

[0018] like figure 1 Or 2 is a schematic structural diagram of an oil-gas separator in the prior art, and its structure has been introduced in detail in the background technology section, so it will not be repeated here.

[0019] The oil-gas separator of the present invention is composed of an upper cover 1, a cylinder body 2, an air outlet pipe 3, an air inlet pipe 4, a filter screen 5 and an oil return pipe, the upper cover 1 is connected with the cylinder body 2 to form a cavity, and the upper cover 1 is marked with Two through holes for air outlet pipe 3 and air inlet pipe 4 to pass through, and at the passing position, air outlet pipe 3 and air inlet pipe 4 are respectively connected to upper cover 1, and the filter screen 5 is provided with a hollow part 10, and the air outlet pipe 4 is connected to the upper cover 1 respectively. The air pipe 3 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com