Oil-gas separator of refrigerating system

A technology of oil-gas separator and refrigeration system, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve problems such as large fluctuations in oil level of compressors, burnout of compressors, failure of oil-gas separators to supply emergency oil to compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

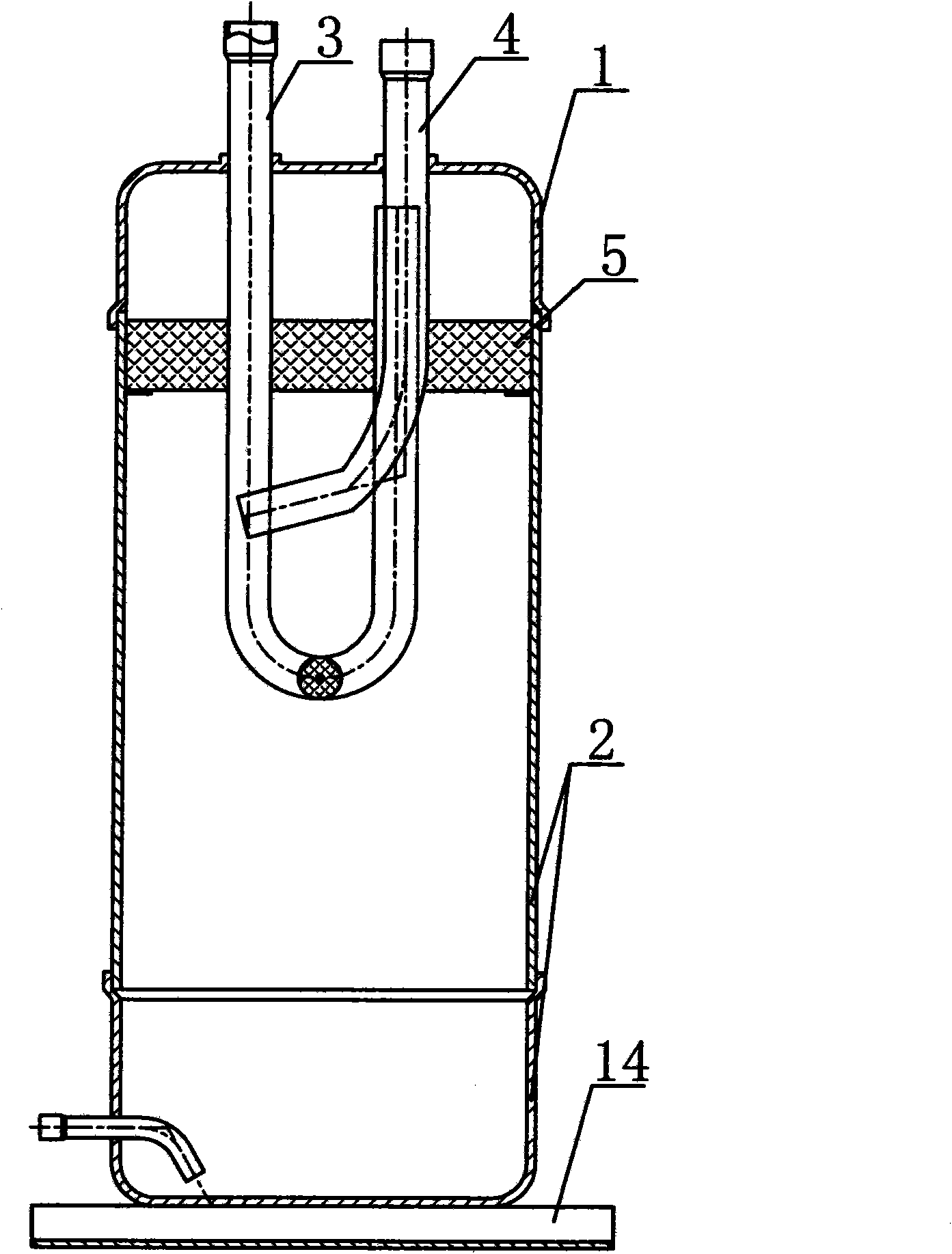

[0016] like figure 1 Or 2 shows the structure schematic diagram of the oil-gas separator of the prior art refrigeration system, it is made up of loam cake 1, cylinder body 2, outlet pipe 3, air inlet pipe 4, filter screen 5 and oil return pipe, and filter screen 5 is horizontally installed on In the cylinder 2, the cavity formed by the connection of the upper cover 1 and the cylinder 2 is divided into upper and lower cavities, the cylinder 2 is installed on the base 14, and the filter screen 5 is punched with three through holes, two of which are air supply pipes 3 through the use, the purpose is to make the curved section of the air outlet pipe 3 be located in the lower cavity, and the air inlet of the air outlet pipe 3 is located in the upper cavity, and the remaining through holes are used for the air inlet pipe 4 to pass through, so that the outlet of the air inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com