Preparation technology of superfine steel slag micropowder and production process

A technology of ultra-fine steel slag powder and production process, which is applied in the direction of process efficiency improvement, solid separation, magnetic separation, etc., and can solve the problems of difficulty in processing steel slag and low removal rate of metallic iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

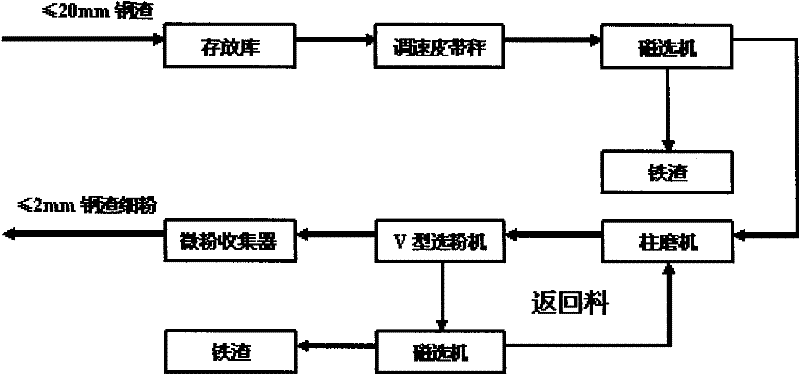

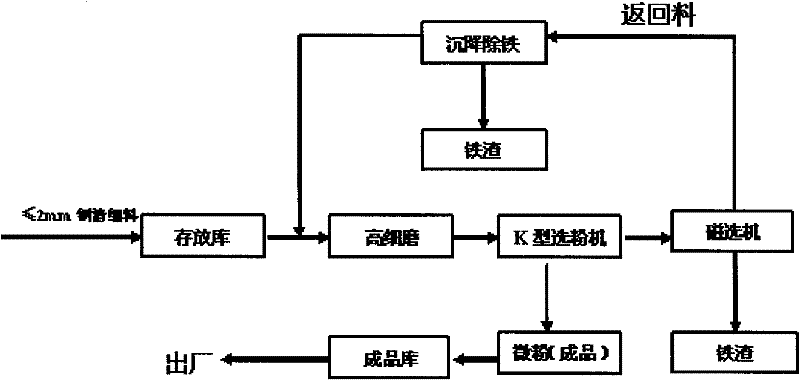

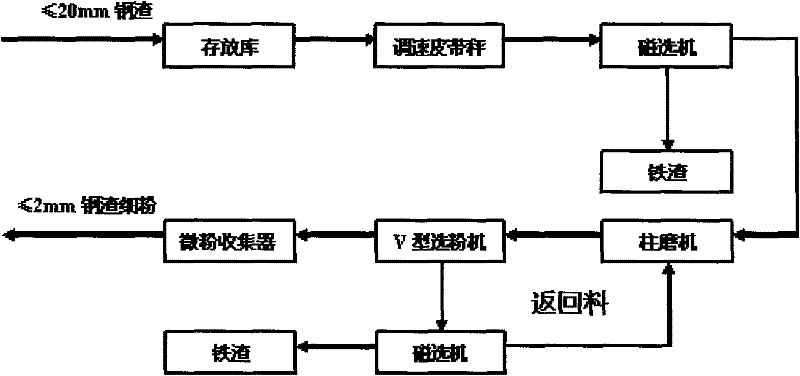

[0014] The steel slag tailings particles (≤20mm) provided by a Shanghai Iron and Steel Co., Ltd. go through the drying and magnetic separation process, and enter the pre-grinding closed-circuit circulation system through electronic weighing. The column mill is used for grinding, and the feed (20-25 ) t, the fineness of the grinding material is controlled to be ≤35.0% (2.5mm sieve), and the material flows into the classification process consisting of a V-type powder separator and a fine powder collector (V-type powder separator cycle load = 120%), after classification The coarse material is returned to the column mill for circular grinding after magnetic separation and iron removal, and the fine material (2.5mm sieve residue = 1.3%, metallic iron = 0.95%) enters the final grinding closed circuit system; the high-fine grinding feeds 36 per hour tons, the fineness of the material to be milled is controlled (28-29)% (45μm sieve residue), the speed of the K-type powder separator is ...

Embodiment 2

[0016] The ≤25mm steel slag tailings particles provided by a steel factory in Nanjing are sent to the column mill by electronic weighing after drying and magnetic separation. 30.0% (remainder of 2.5mm sieve), the material flows into the classification process composed of V-type powder separator and fine powder collector (the cycle load of V-type powder separator is 125%), after classification, the coarse material returns to the column mill after magnetic separation and iron removal The machine performs circular grinding, and the fine material (2.5mm sieve residue = 1.5%, metallic iron content = 0.75%) enters the final grinding closed loop system; the high-fine grinding feeds 40 tons per hour, and the fineness of the grinding material is controlled ( 26~27)% (remainder of 45μ sieve), the speed of K-type powder separator N=270 / min, the specific surface area of the selected ultra-fine steel slag powder is 635m 2 / kg, ultra-fine steel slag powder with a particle size of less tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com