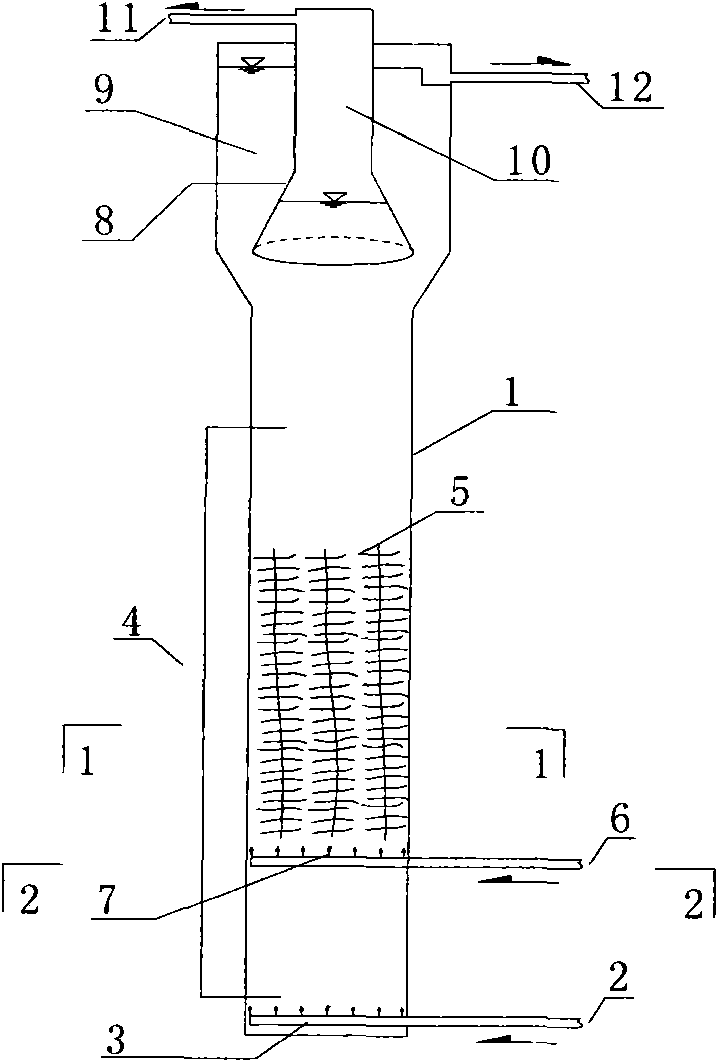

Integrated two-phase anaerobic reactor

An anaerobic reactor and reactor technology, applied in the field of water treatment, can solve the problems of large floor space, high construction and operation costs, uneven distribution of sludge, etc., and achieve the effect of increasing biomass and improving wastewater treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Reconstruction of the existing upflow anaerobic reactor: treatment of cornstarch sugar production wastewater, the basic parameters of wastewater are shown in Table 1:

[0015]

[0016] The original process adopts: regulating pool-UASB-SBR

[0017] The design hydraulic retention time of the regulating tank is 3.5h, the UASB design hydraulic retention time is 28h, and the SBR design hydraulic retention time is 14h. In April 2008, the factory expanded the sugar workshop, and the designed production capacity increased by 30% compared with the original one, and the corresponding amount of waste water produced was also 400m 3 / d raise to 520m 3 / d, for the increase of water volume, the average effluent COD of the existing UASB reactor increased from 980mg / L to 1525mg / L, making the subsequent SBR process effluent unable to meet the original design requirements. In June 2008, the UASB reactor was rebuilt, and elastic three-dimensional packing was added in the reaction area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com