Method for preparing gamma-Fe2O3 nanometer wire filling carbon nitrogen multi-wall nanometer tubes through one-step reaction

A technology of multi-walled nanotubes and nanowires, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of large diameter distribution of carbon-based nanotubes, difficulty in obtaining filling effect and yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

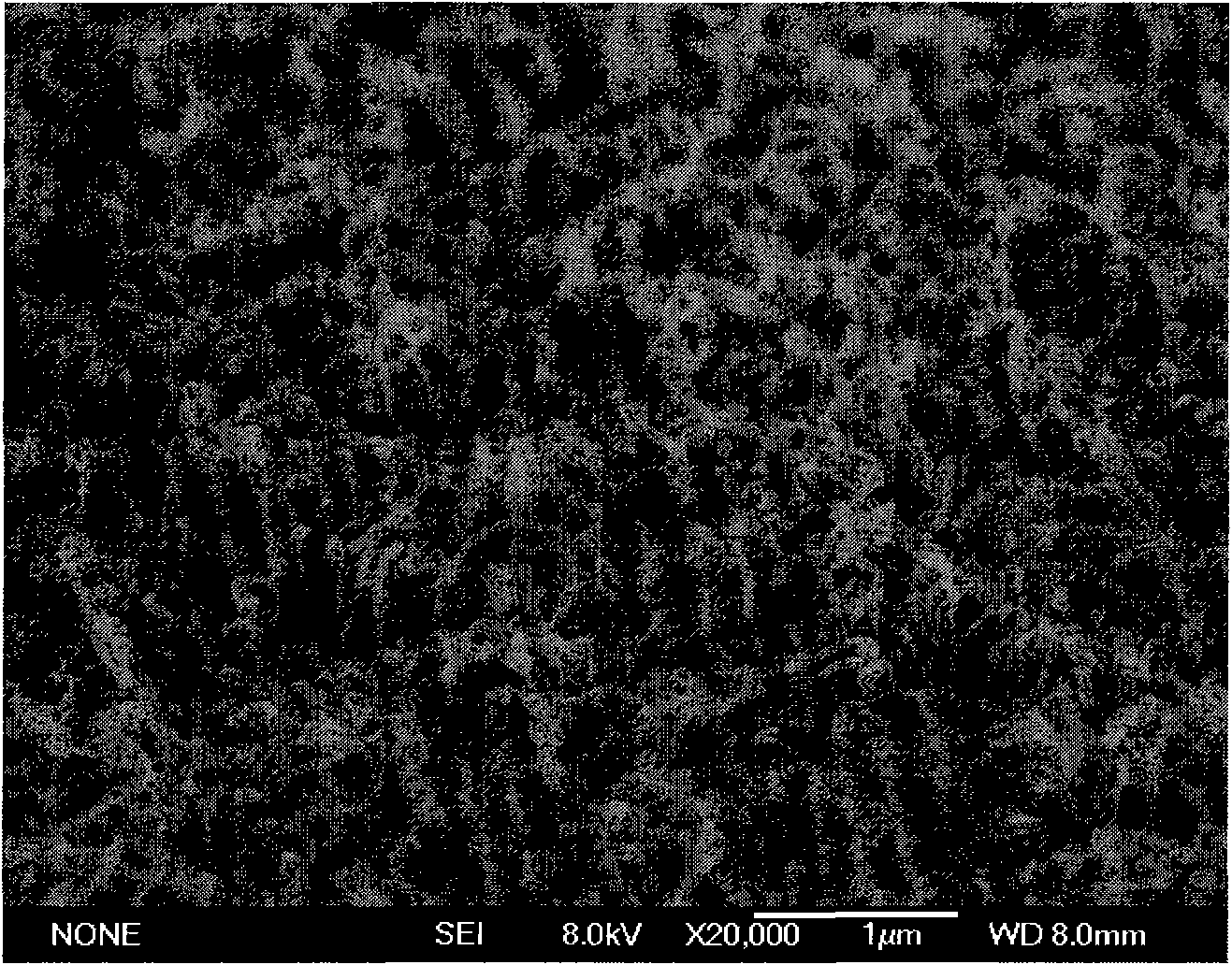

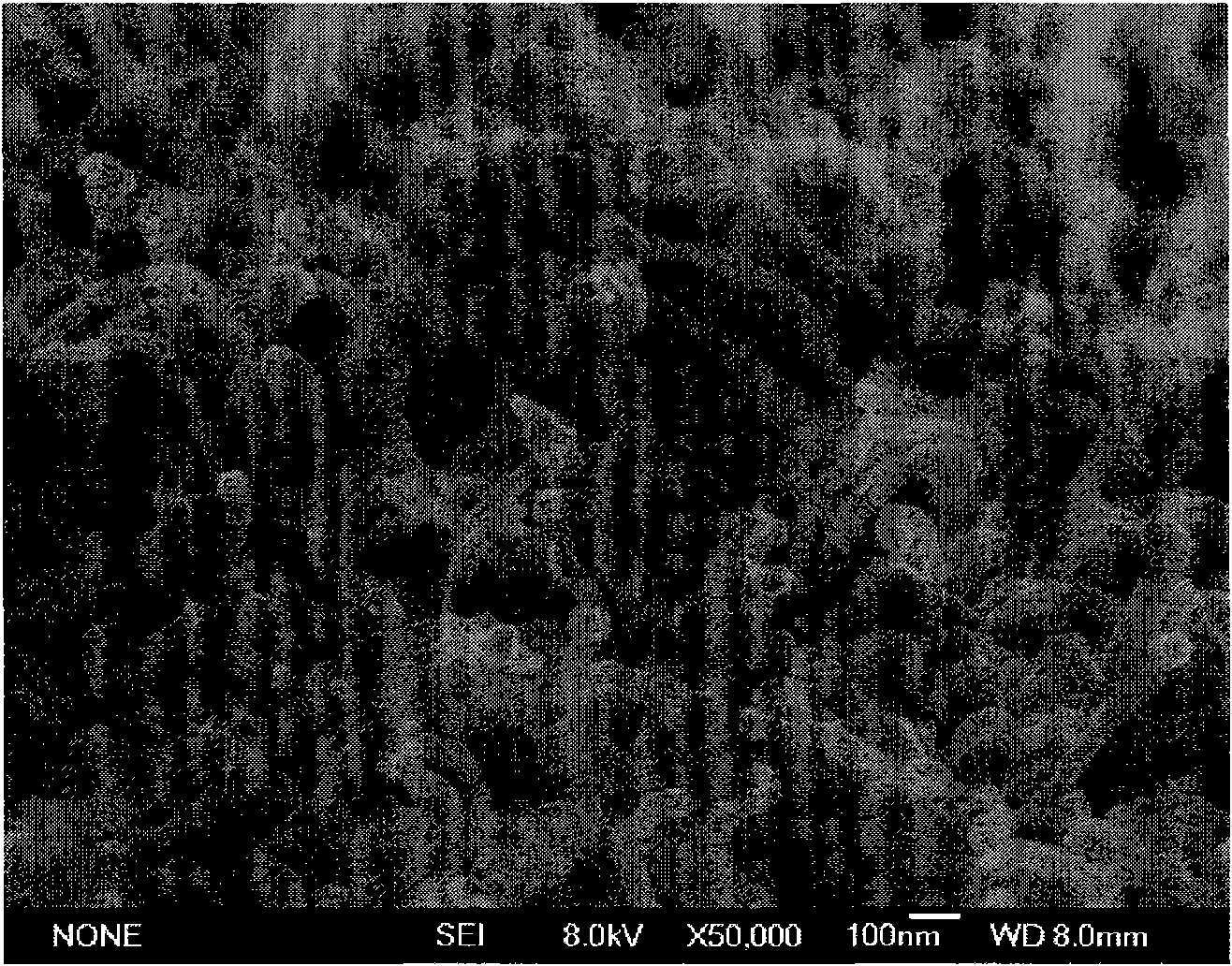

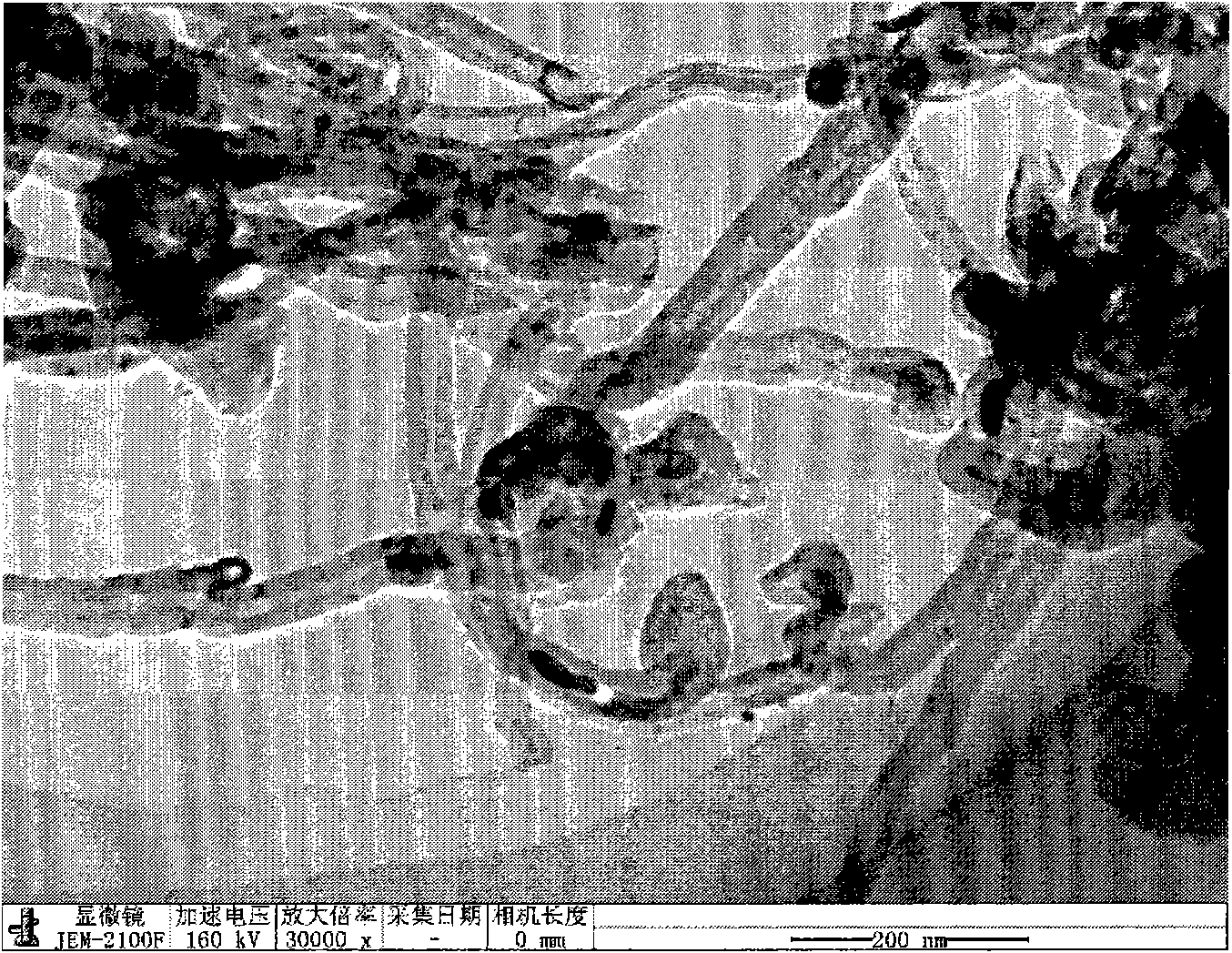

[0042] Preparation of γ-Fe 2 o 3 The experimental conditions and parameters of carbon nitrogen nanotubes are as follows:

[0043] 1) deposition thickness is 8~10nm thick FeNi (Fe50%Ni50%, mass fraction) catalyst thin film on substrate: select Si (111) for use as substrate, by target magnetron sputtering PVD equipment (chosen in the present invention The JGP450A multi-target magnetron sputtering PVD equipment) was used for physical vapor deposition of catalyst thin films. The specific parameters are as follows: the sputtering current of the Ti target is 0.2A, the sputtering voltage is 230V, the sputtering gas is argon, the flow rate is 30sccm, the gas pressure is 0.6Pa, the substrate bias voltage-100V, and the deposition time is 220s; FeNi ( Fe50%, Ni50%, mass fraction) the excitation current of the alloy target is 2.2A, the excitation voltage is 17.5V, the sputtering current is 0.4A, the sputtering voltage is 300V, the sputtering gas is argon, the flow rate is 80sccm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com