Ink-jet recording material used for full-face spray light box film

An inkjet recording material and film technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of inkjet film such as poor waterproof performance, strong film brittleness, and low pattern density, so as to ensure inkjet printing performance, Solve the effect of yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

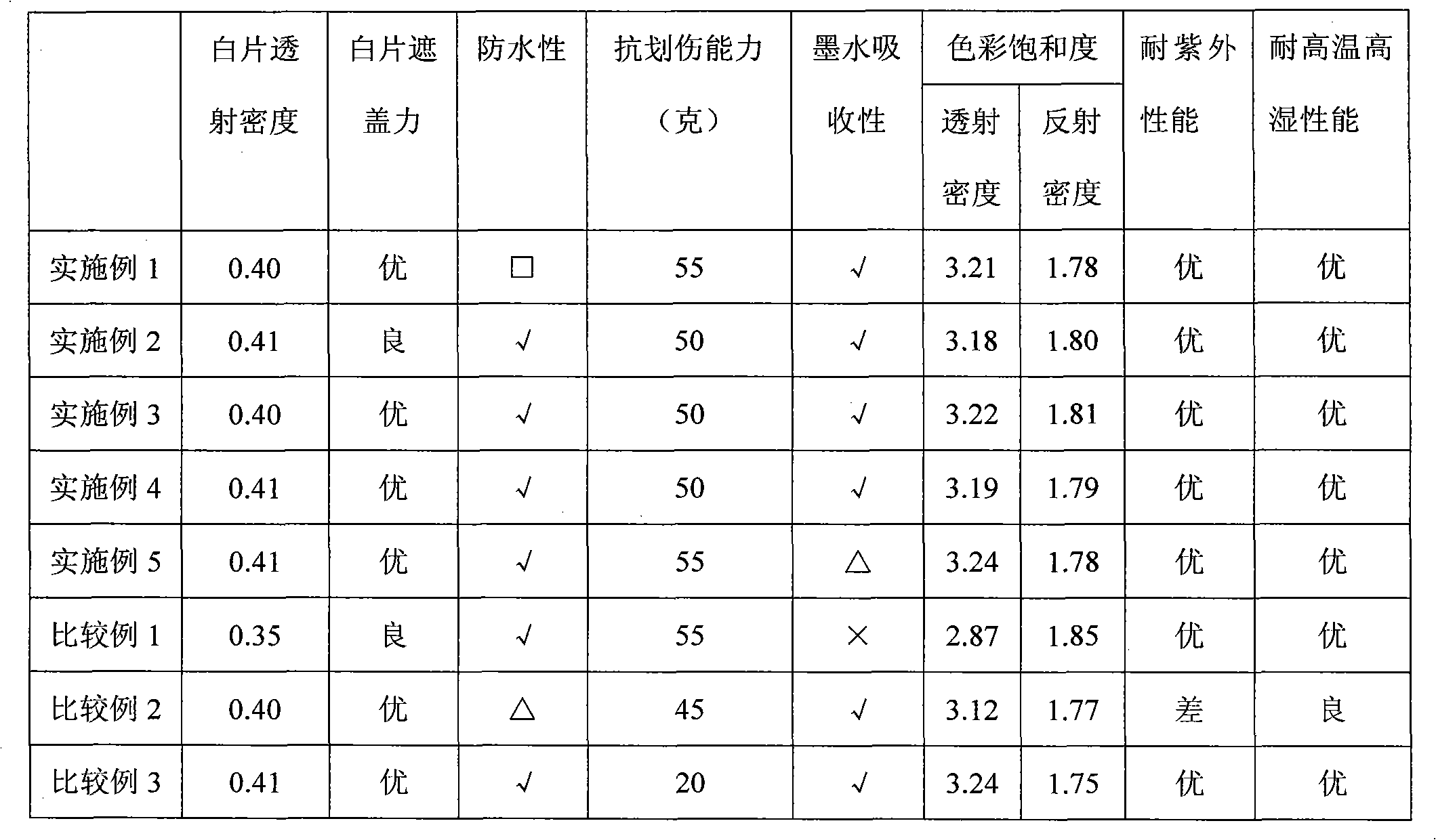

Examples

Embodiment 1

[0033] Preparation of ink-absorbing covering layer coating solution:

[0034] Precipitated silica (Beijing Aerospace Saide SD-520, average particle size about 2 microns) 100 parts

[0035] Dimethyl diallyl ammonium chloride copolymer (average molecular weight is 50000) 10 parts

[0036] Polyvinyl alcohol (Kuraray pva235 saponification degree 88%, average polymerization degree 3500) 20 parts

[0037] Boric acid (Tianjin Hengxing Chemical Reagent) 5 parts

[0038] Titanium dioxide (average particle size about 10 nanometers) 20 parts

[0039] Water-based ethylene-vinyl acetate copolymer emulsion (Dalian Chemical DA-100L, Taiwan) 6 parts

[0040] Water-based polyurethane emulsion (Superflex 650 from Daiichi Industry Co., Ltd.) 24 parts

[0041] Sodium hexametaphosphate (Tianjin No. 6 Chemical Reagent Factory No. 3 Branch Factory) 0.5 parts

[0042] OP-10 (Tianjin Fuchen Reagent) 0.5 parts

[0043] 614 parts of deionized water

[0044] Precipitated silicon dioxide is dispers...

Embodiment 2

[0059] Preparation of ink-absorbing covering layer coating solution:

[0060] Precipitated silica (Beijing Aerospace Saide SD-960, average particle size about 10 microns) 100 parts

[0061] Dimethyl diallyl ammonium chloride copolymer (average molecular weight is 50000) 12 parts

[0062] Polyvinyl alcohol (Kuraray pva235 saponification degree 88%, average polymerization degree 3500) 20 parts

[0063] Boric acid (Tianjin Hengxing Chemical Reagent) 5 parts

[0064] Titanium dioxide (average particle size about 100 nanometers) 20 parts

[0065] Water-based ethylene-vinyl acetate copolymer emulsion (Dalian Chemical DA-100L, Taiwan) 15 parts

[0066] Water-based polyurethane emulsion (Superflex 650 from Daiichi Industry Co., Ltd.) 24 parts

[0067] Sodium hexametaphosphate (Tianjin No. 6 Chemical Reagent Factory No. 3 Branch Factory) 0.5 parts

[0068] OP-10 (Tianjin Fuchen Reagent) 0.5 parts

[0069] 614 parts of deionized water

[0070] Precipitated silicon dioxide is disper...

Embodiment 3

[0084] Preparation of ink-absorbing covering layer coating solution:

[0085] Precipitated silica (Grace P-508, average particle size about 0.5 microns) 100 parts

[0086] Dimethyl diallyl ammonium chloride copolymer (average molecular weight is 50000) 3.6 parts

[0087] Polyvinyl alcohol (Kuraray pva235 saponification degree 88%, average polymerization degree 3500) 20 parts

[0088] Boric acid (Tianjin Hengxing Chemical Reagent) 5 parts

[0089] Titanium dioxide (average particle size about 500 nanometers) 20 parts

[0090] Water-based ethylene-vinyl acetate copolymer emulsion (Dalian Chemical DA-100L, Taiwan) 60 parts

[0091] Water-based polyurethane emulsion (Superflex 650 from Daiichi Industry Co., Ltd.) 24 parts

[0092] Sodium hexametaphosphate (Tianjin No. 6 Chemical Reagent Factory No. 3 Branch Factory) 0.5 parts

[0093] OP-10 (Tianjin Fuchen Reagent) 0.5 parts

[0094] 614 parts of deionized water

[0095] Precipitated silicon dioxide is dispersed into a stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com