Continuous production process and production device of inorganic light aggregate thermal insulation mortar

A technology of inorganic light aggregate and thermal insulation mortar, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of improper mixing method, unstable product quality, poor process operability, etc., and achieve simplified production operations methods, improving labor productivity, and simplifying the effect of process operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

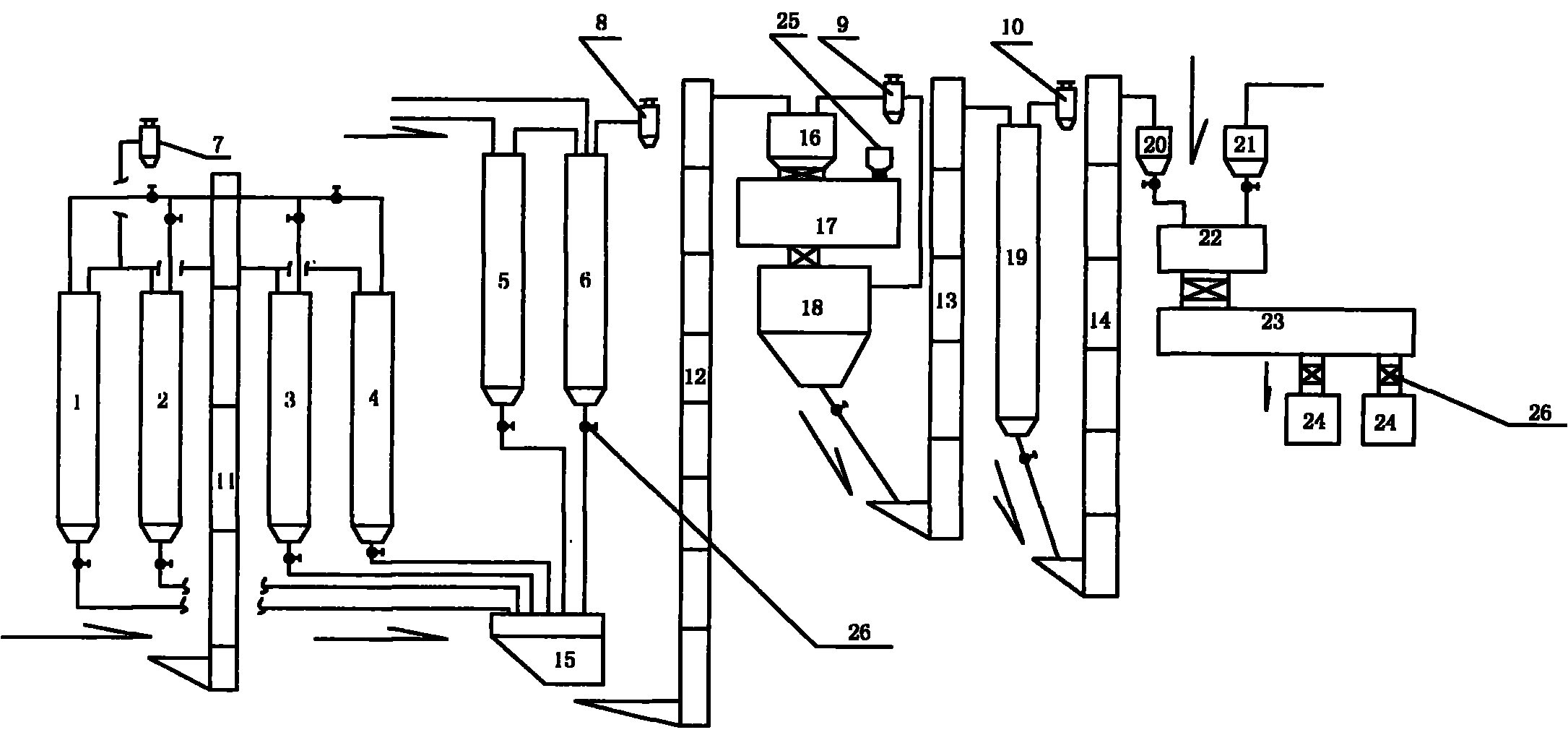

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

[0043] A continuous production process for inorganic lightweight aggregate heat preservation mortar, comprising the following steps:

[0044] (1) After measuring and batching cement, fly ash, inorganic filler and functional filler, stir and mix to produce inorganic gelling powder, wherein the weight ratio of cement, fly ash and inorganic filler is 700-900:60 ~200:50~300;

[0045] (2) After the inorganic gelling powder and inorganic light aggregate are measured and proportioned, they are stirred and mixed to produce inorganic light aggregate thermal insulation mortar, wherein the weight-to-volume ratio of inorganic gelling powder and inorganic light aggregate is 1:5 ~8.2Kg / L;

[0046] (3) Inorganic light aggregate thermal insulation mortar is then measured and packaged to obtain the finished product.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com