Submersible servodrive system

A drag system and submersible oil technology, applied in the field of drag systems, can solve the problems of lower oil production costs, lower system efficiency, low energy saving rate, and faster motor temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

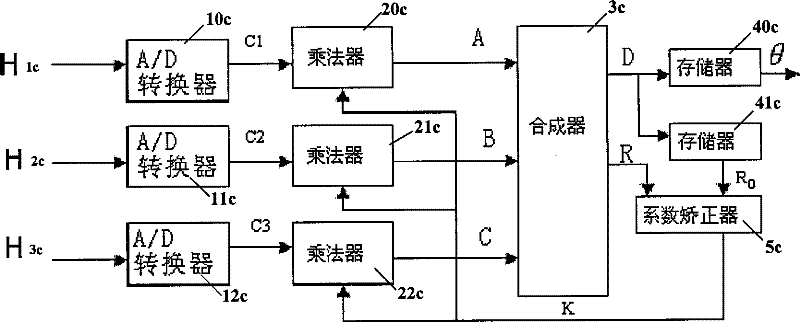

[0132] Figure 21 is a block diagram of a signal processing device of a position detecting device solution equipped with two magnetic induction elements according to a first embodiment of the present invention. Magnetic induction element H 1a and H 2a The output signal of the output signal is connected to the built-in A / D converter analog input port of the MCU, and the output signal obtained after the analog-to-digital conversion is connected to the multipliers 20a, 21a, and the output signal K of the coefficient corrector 5a is connected to the input terminals of the multipliers 20a, 21a, and the multiplication The output signals of the devices 20a, 21a are connected to the input terminals of the synthesizer 3a, and the synthesizer 3a outputs signals D and R, and the coefficient corrector 5a receives the signals D and R output by the synthesizer 3a, obtains the signal K through operation, and makes the magnetic induction element H 1a and H 2a The signal of K is multiplied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com