Light diesel preparation method

A diesel and light-weight technology, which is applied in the petroleum industry, biofuels, liquid carbon-containing fuels, etc., can solve the problems of diesel engines such as insufficient power, unstable operation, and long ignition delay period, and achieve good combustion and low-temperature fluidity, The effect of low cost and short flame delay period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 250kg of pine oil is heated for fractional distillation, and a total of 100kg of distillate below 260-280℃ is harvested as light oil, and the remaining liquid is heavy oil. Add 5.5 kg of 99% sodium hydroxide and 10 kg of water to the obtained light oil, fully stir for 25 minutes, and separate the clear oil from the residual liquid after 1.5 hours of precipitation, and re-precipitate the separated clear oil in the precipitation tank 52 hours. After the oil residue is separated, the obtained clear oil is heated and distilled, and the fraction at 150-220°C is collected, namely the vegetable product oil. The extracted vegetable oil and the national standard biodiesel prepared from waste animal and vegetable oils are compounded at 45:55 to obtain the light diesel of the present invention.

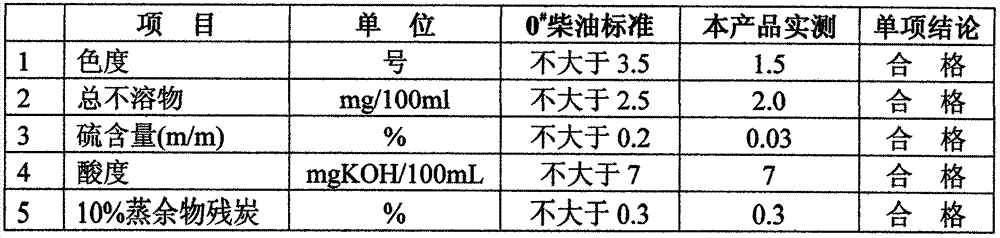

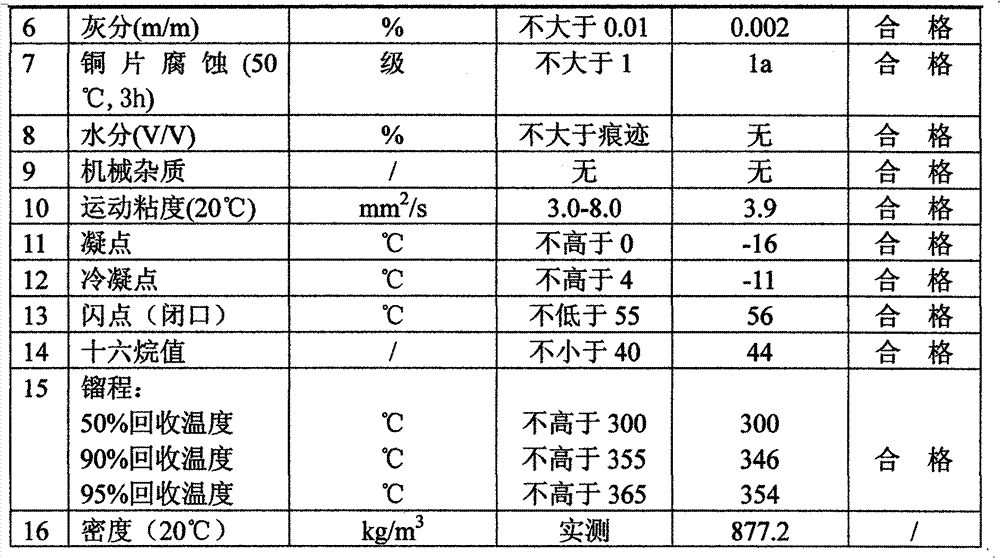

[0022] The light diesel of the present invention has been verified by the Hunan Provincial Commodity Quality Supervision and Inspection Institute and is based on the GB252-2000 "Light Diese...

Embodiment 2

[0027] 250kg of pine oil is heated for fractional distillation, and a total of 98kg of fractions below 260-280°C are harvested as light oil, and the remaining liquid is heavy oil. Add 5.2 kg of sodium hydroxide with a content of 99.2% and 9.8 kg of water to the obtained light oil, fully stir for 30 minutes, and separate the clear oil from the residual liquid after 1.25 hours of precipitation, and then place the separated clear oil in the precipitation tank. Settling for 55 hours. After the oil residue is separated, the obtained clear oil is heated and distilled, and the fraction at 150-220°C is collected, namely the vegetable product oil. The extracted vegetable oil and the national standard biodiesel prepared from waste animal and vegetable oils are compounded at 45:55 to obtain the light diesel of the present invention. The verification results are the same as in Example 1.

Embodiment 3

[0029] 250kg of pine oil is heated for fractional distillation, and a total of 104kg of distillate below 260-280℃ is harvested as light oil, and the remaining liquid is heavy oil. Add 6.03 kg of 99.5% sodium hydroxide and 10.4 kg of water to the obtained light oil, fully stir for 35 minutes, and separate the clear oil from the residual liquid after 1.5 hours of precipitation. The separated clear oil is re-introduced in the precipitation tank. Settling for 50 hours. After the oil residue is separated, the obtained clear oil is heated and distilled, and the fraction at 150-220°C is collected, namely the vegetable product oil. The extracted vegetable oil and the national standard biodiesel prepared from waste animal and vegetable oils are compounded at 45:55 to obtain the light diesel of the present invention. The verification results are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com