Resistance reducing acid used for transformation of ultra-deep well

A technology for ultra-deep wells and resistance reduction, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of restricting the development and utilization of high-temperature deep oil and gas resources, restricting the reformation of reservoirs, etc., so as to increase construction displacement, reduce The effect of additional energy consumption and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

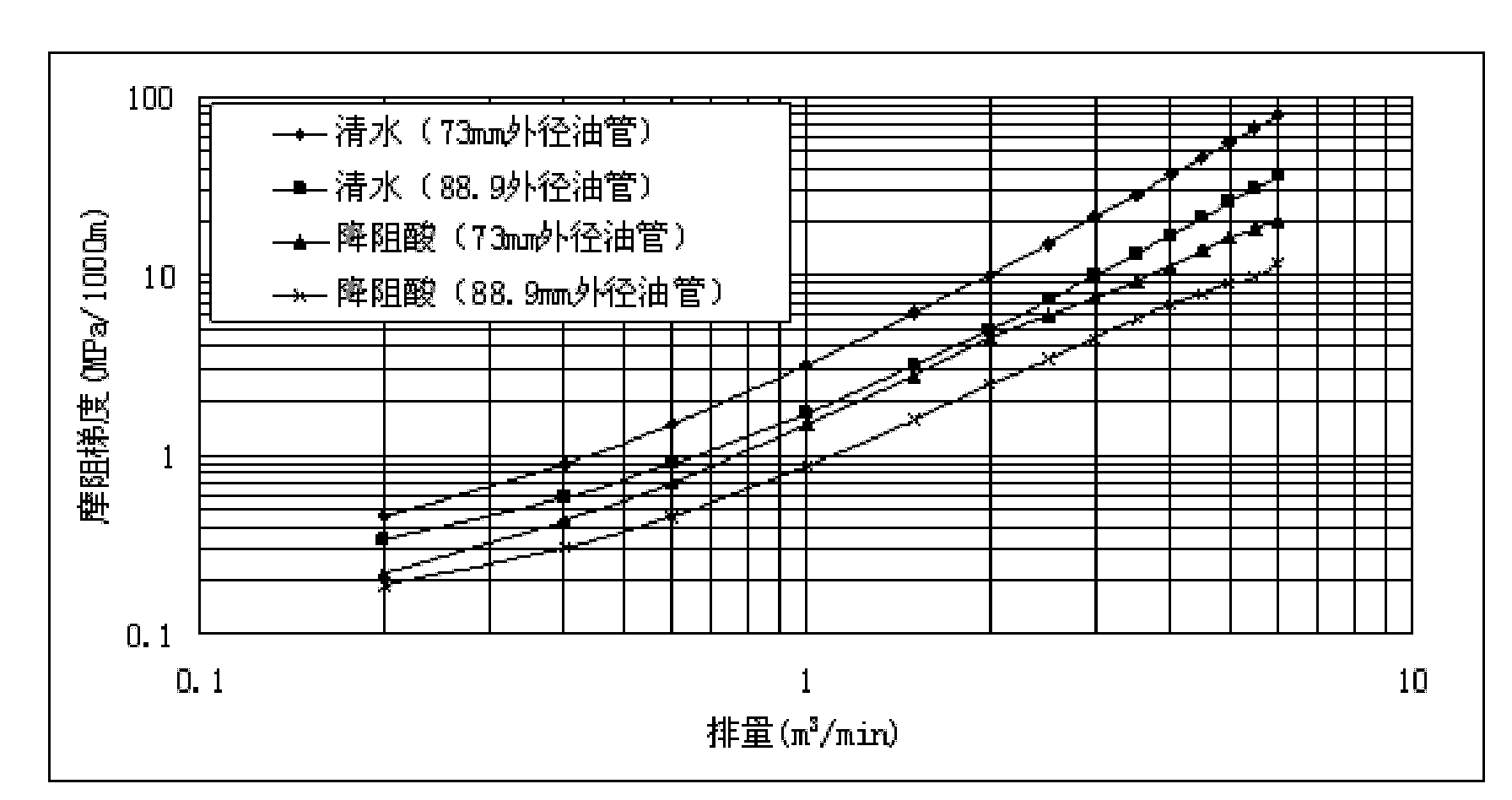

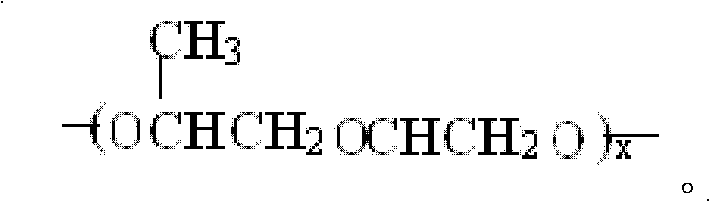

[0028] 2.0% by weight of ethylene glycol-1,2-propanediol copolymer, 2.0% by weight of β-(N,N)-diethylamino phenyl ketone, 1.0% by weight of dodecyl trimethyl chloride Ammonium, 1.0% by weight of sodium erythorbate, 28% by weight of hydrochloric acid, and the balance being water, are equipped with a barrier-reducing acid.

[0029] The acid density is 1.14g / cm 3 , viscosity 11.4mPa.s, surface tension 28.4mN / m, 90°C static corrosion rate 3.32g / m 2 .h, iron ion stability capacity 2260mg / L, 88.9mm pipe diameter, 3.0m 3 / min, friction gradient 7.85MPa / 1000m, 120 ℃, 4h without delamination, no precipitation, good thermal stability.

Embodiment 2

[0031] By 2.0% by weight of ethylene glycol-1,2-propanediol copolymer, 2.0% by weight of β-(N,N)-diethylamino phenyl ketone, 1.0% by weight of dodecyl trimethyl bromide Ammonium, 1.0% by weight of hydroxylamine hydrochloride, 28% by weight of hydrochloric acid, and the balance being water, are used to prepare a barrier acid.

[0032] The acid density is 1.14g / cm 3 , viscosity 11.8mPa.s, surface tension 27.9mN / m, 90℃ static corrosion rate 3.26g / m 2 .h, iron ion stability 2235mg / L, 88.9mm pipe diameter, 3.0m 3 / min, friction gradient 7.70MPa / 1000m, 120 ℃, 4h without delamination, no precipitation, good thermal stability.

Embodiment 3

[0034] According to 4.0% by weight of ethylene glycol-1,2-propanediol copolymer, 4.0% by weight of β-(N,N)-diethylamino phenyl ketone, 2.0% by weight of dodecyl trimethyl chloride Ammonium, 2.0% by weight of sodium erythorbate, 28% by weight of hydrochloric acid, and the balance being water, are equipped with a barrier-reducing acid.

[0035] The acid density is 1.14g / cm 3 , viscosity 26.7mPa.s, surface tension 27.1mN / m, 90℃ static corrosion rate 1.74g / m 2 .h, iron ion stability 3345mg / L, 88.9mm pipe diameter, 3.0m 3 / min, friction gradient 4.96MPa / 1000m, 120 ℃, 4h without delamination, no precipitation, good thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com