Polishing liquid used for gem ball with 10-grade surface finish and preparation method

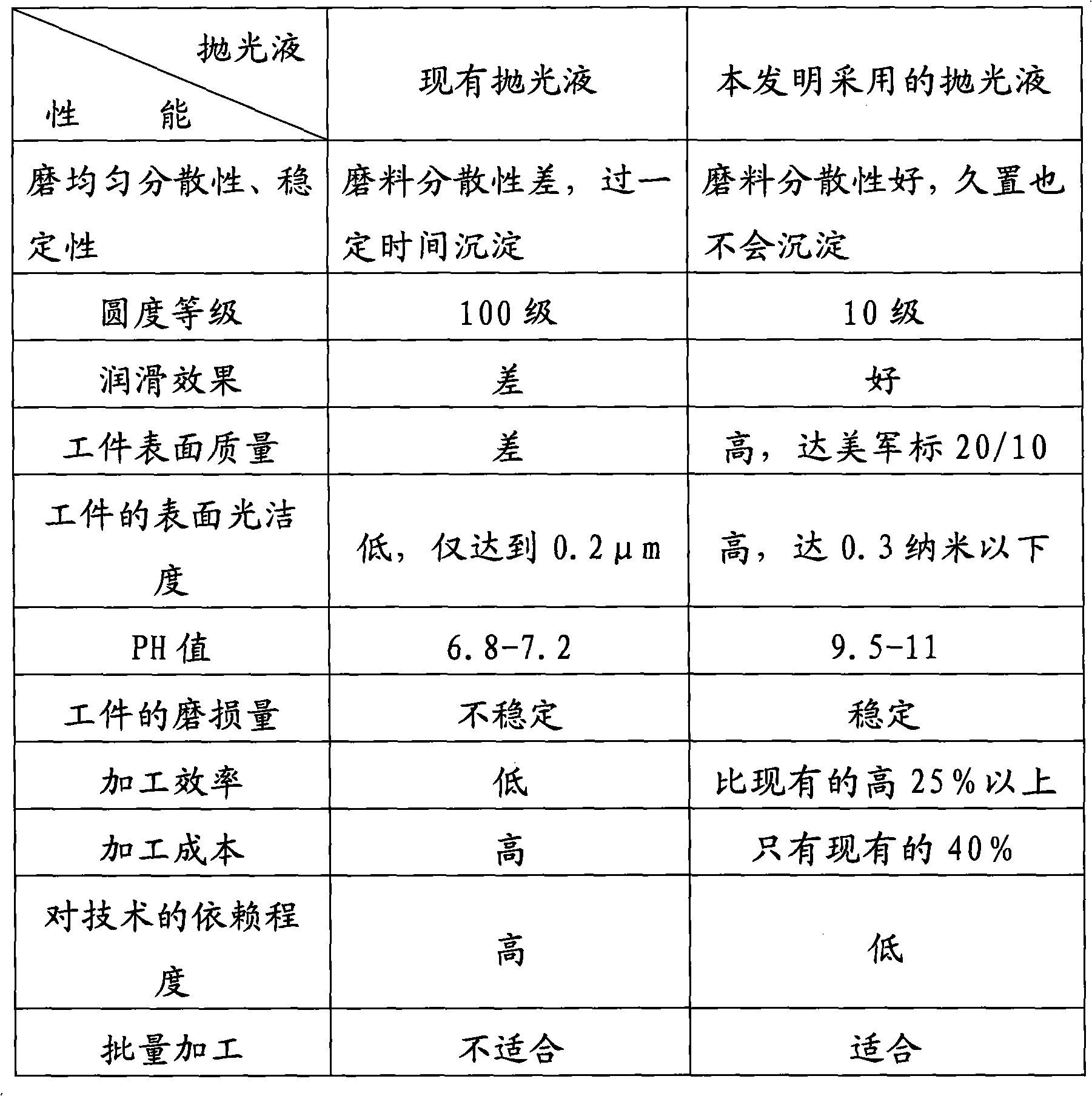

A technology of surface polishing and polishing liquid, which is applied in the field of polishing liquid, can solve the problems of ball scratches, roundness grade not reaching G10, production workers' experience and high technical requirements, etc., so as to reduce costs, improve production efficiency, and show High quality and surface finish results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

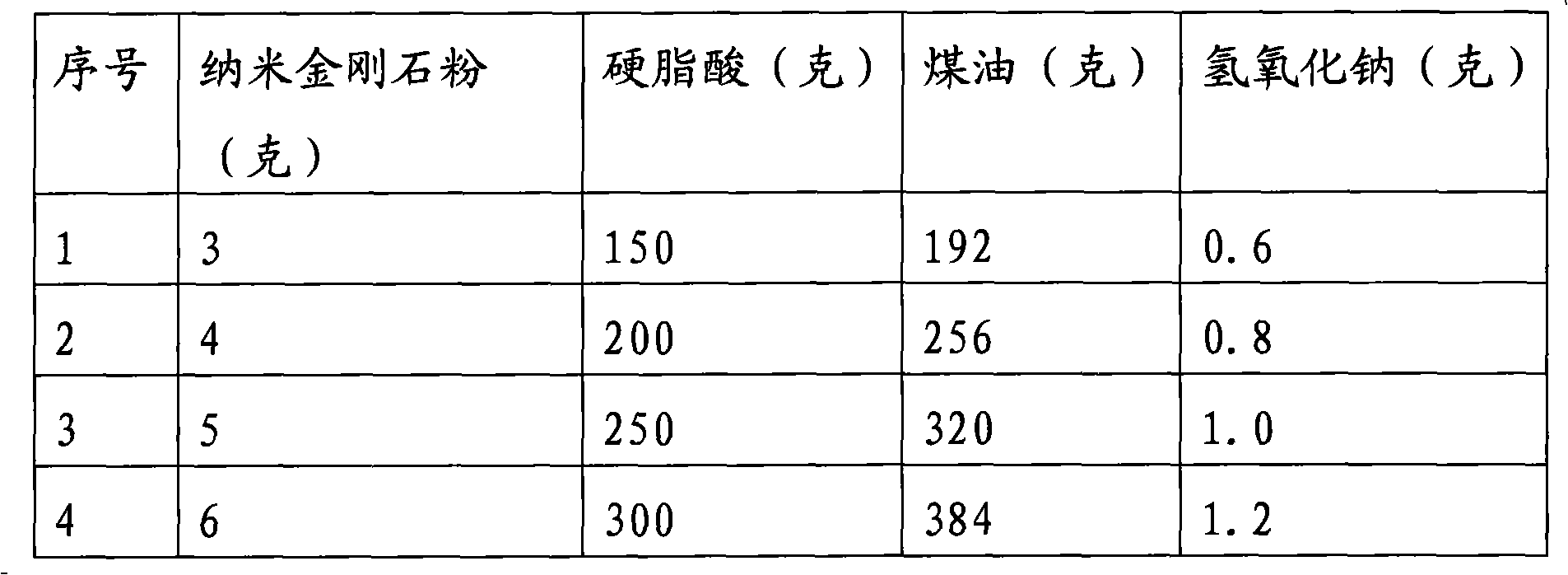

[0033] Each component required for the polishing liquid is configured according to Table 2:

[0034] Table 2

[0035]

[0036] The preparation method of the polishing liquid formula is as follows:

[0037] (1) Weighing: Put a layer of clean white paper on the electronic scale, take out the diamond powder with a medicine spoon and place it on the white paper, and accurately weigh the diamond powder according to Table 2.

[0038] (2) Baking: put the white paper filled with nano-diamond powder together on a heating platform, bake at a temperature of 100° C. for 120 minutes, take out the baked nano-diamond powder, and then cool in air for 30 minutes.

[0039] (3) Grinding: In a medium-sized agate mortar, grind and disperse the agglomerated nano-diamond powder, the amount of each grinding should not exceed 2 grams, and the grinding time should not be less than 30 minutes.

[0040] (4) ultrasonic dispersion: the nano-diamond powder after grinding is placed in the beaker, adds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com