Self-pressure grading system for coarsening period of seeded precipitation

A grading system and roughening technology, applied in the purification of aluminate/alumina/aluminum hydroxide, preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the waste of energy and equipment without considering the impact , the utilization rate of spare parts in the factory and the increase in personnel consumption, etc., to achieve the effect of saving electricity, reducing the number of flushing, and reducing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

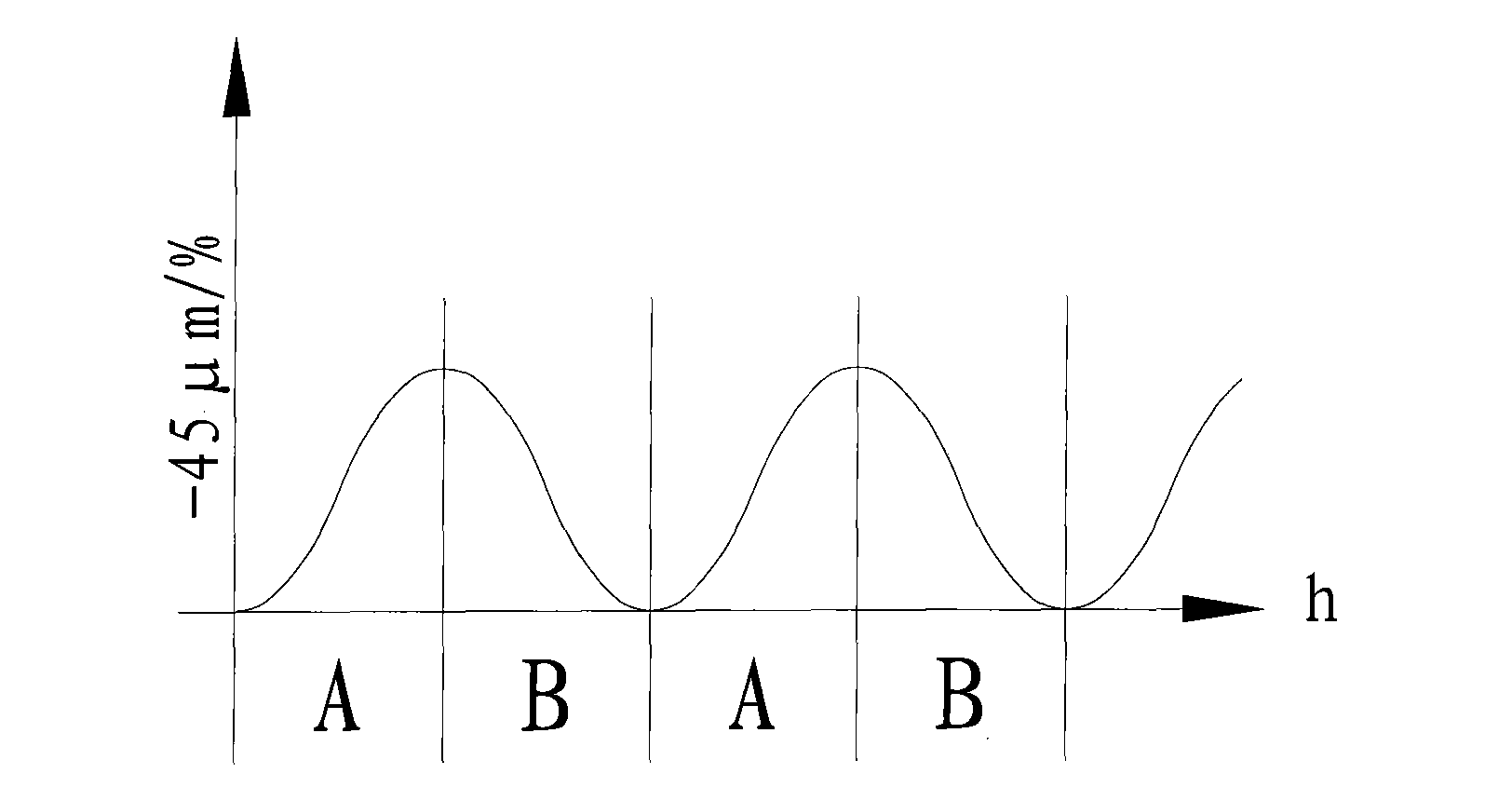

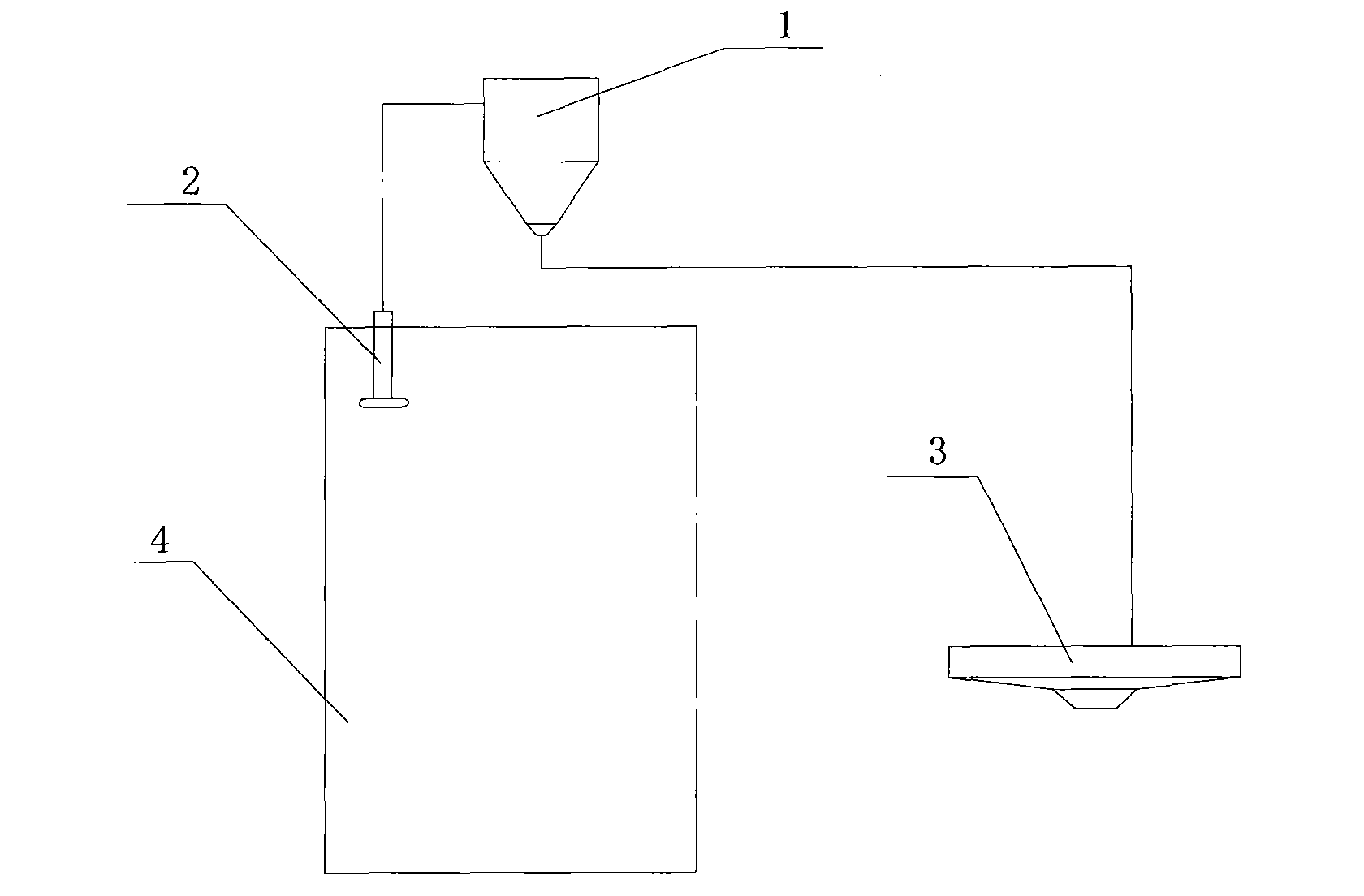

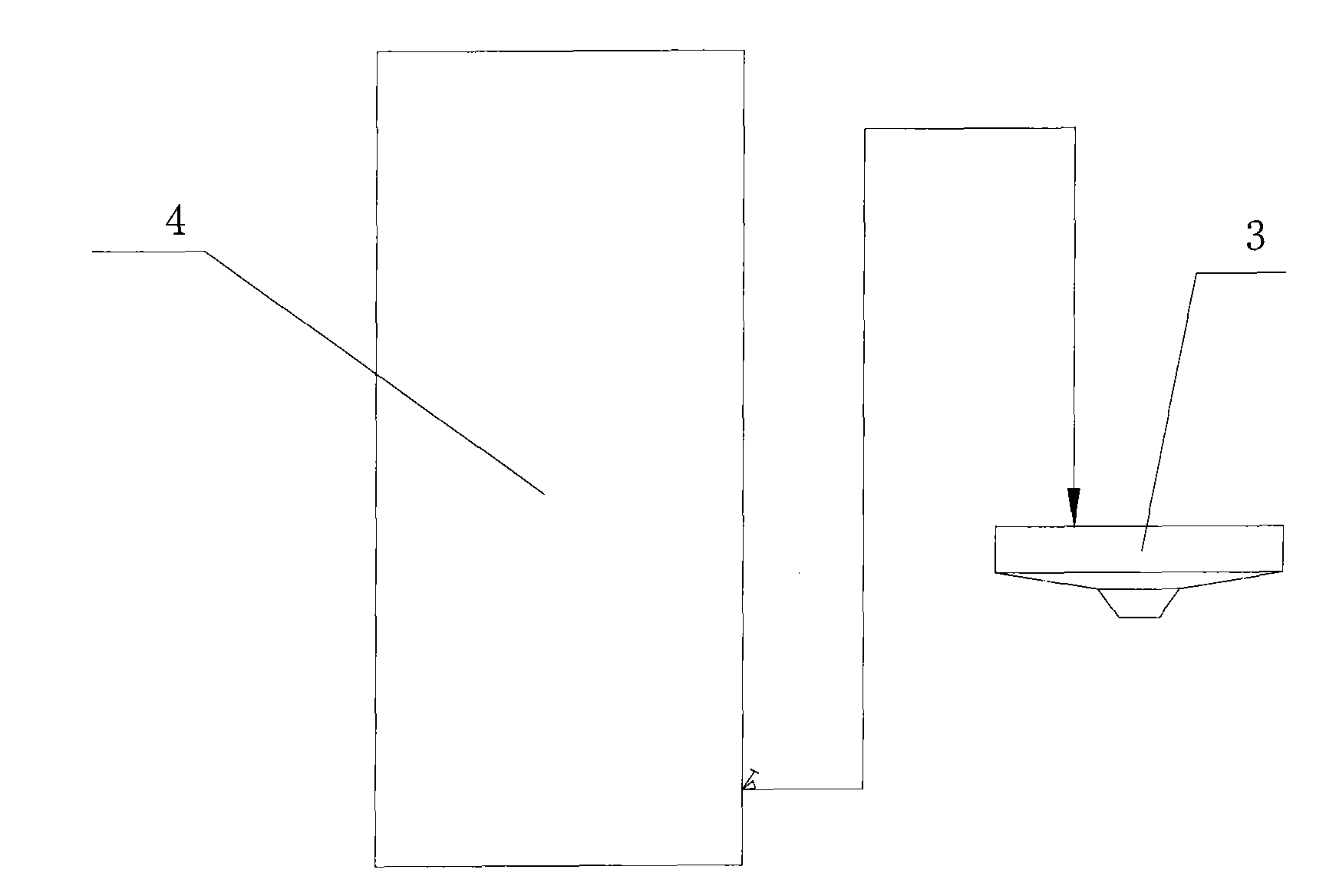

[0015] According to the experimental data, it can be seen that in the coarsening period of classification, the number of seed crystal particles greater than 45 μm (called large particles) is more than 91%. Connect the root pipe, utilize the liquid level difference (generally 35 meters) of the decomposition end tank 4 to make the slurry self-pressed and go to the flat plate filter 3, such as image 3 as shown ( image 3 The arrows in indicate the whereabouts of the classified large particles). In this way, on the one hand, the submerged pump can be used to lift materials during the coarsening period of at least 3 months, and only the classifier and submerged pump can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com