Photocatalytic oxidation-membrane separation circulating fluid bed reaction device

A photocatalytic oxidation and circulating fluidized bed technology, which is applied in oxidation water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult catalyst replacement, membrane peeling, and low reactor processing capacity. Achieve high mass transfer efficiency and light energy utilization, increase reaction speed, and reduce membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and specific embodiments.

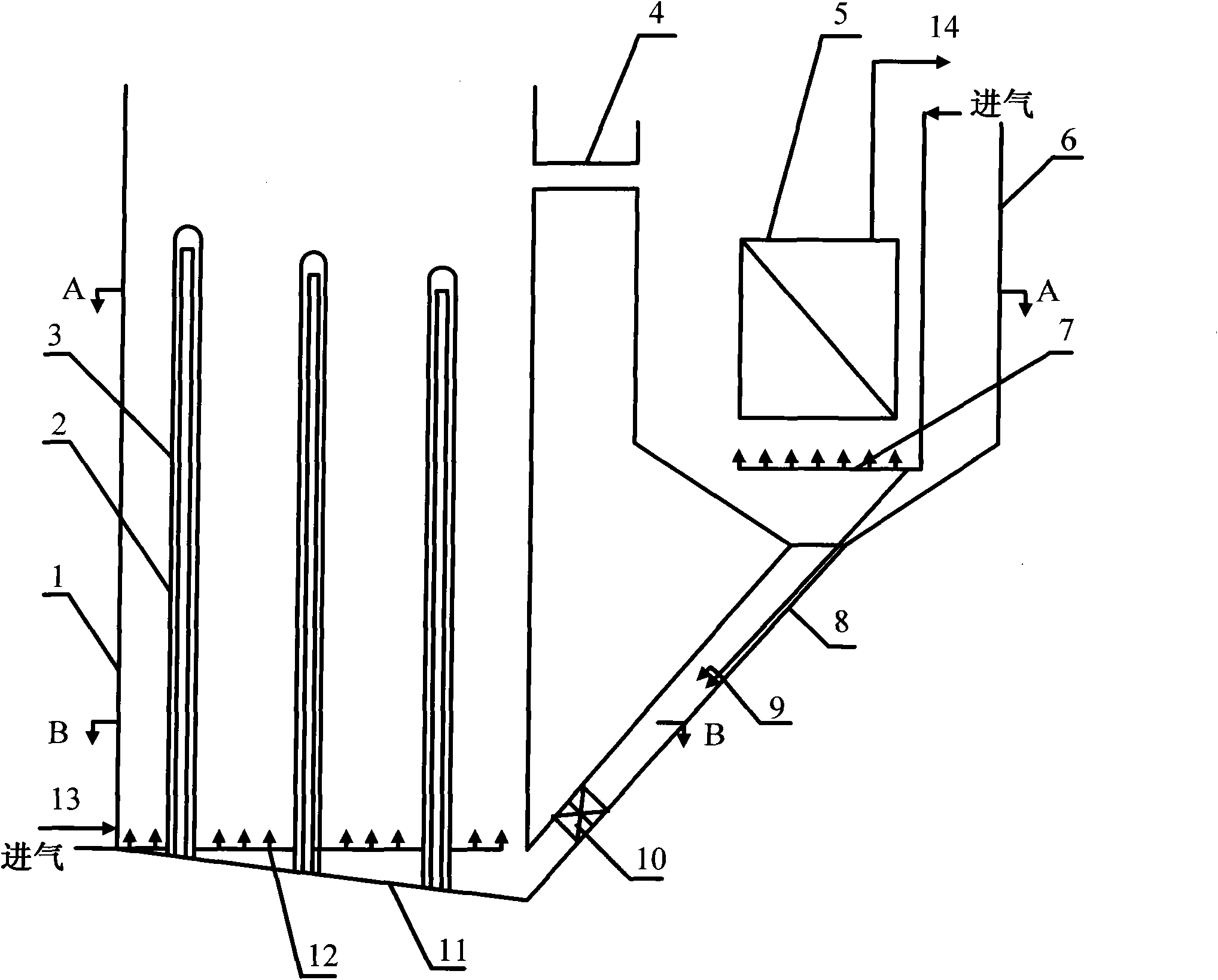

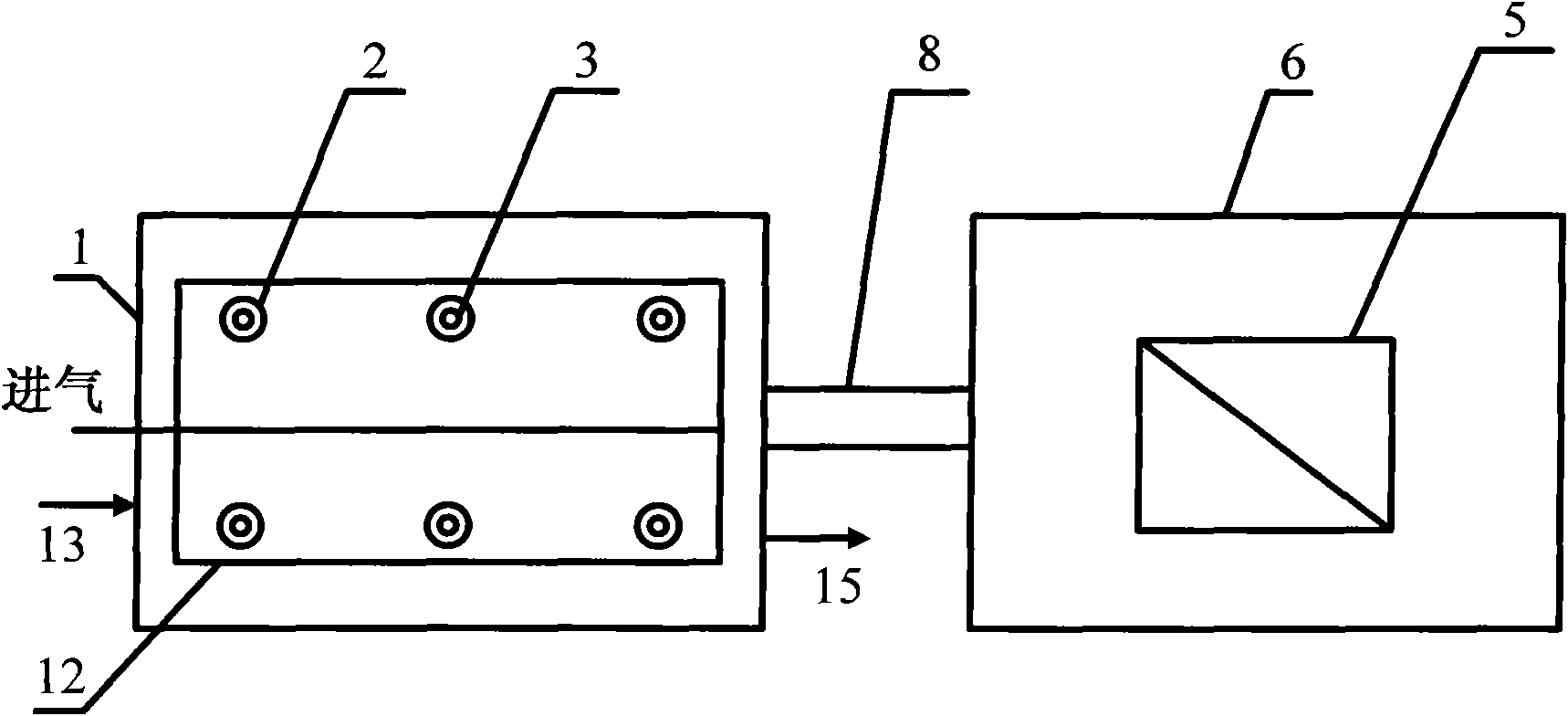

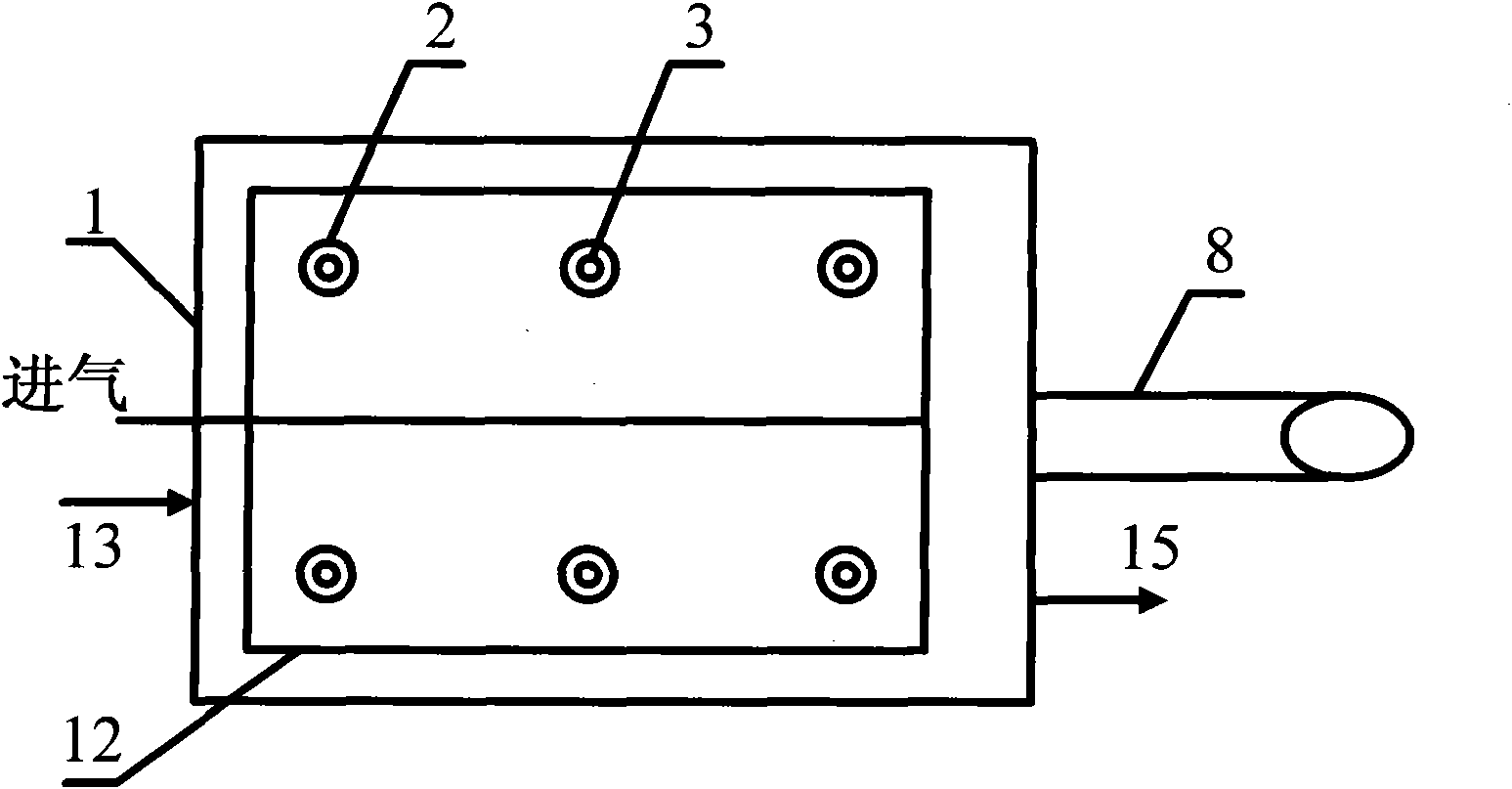

[0021] As shown in the drawings, the photocatalytic oxidation-membrane separation circulating fluidized bed reactor of the present invention includes a photocatalytic reactor 1 and a membrane separation circulating reactor 6, and the photocatalytic reactor includes a photocatalytic reactor shell , The membrane separation circulating reactor includes a membrane separation circulating reactor shell arranged on the upper side of the photocatalytic reactor shell, a plurality of ultraviolet light sources are arranged in the photocatalytic reactor shell, and The immersed membrane module 5 is arranged in the shell of the membrane separation circulating reactor, and the immersed membrane module is connected to the water outlet 14, and the lower part of the photocatalytic reactor shell is provided with a water inlet 13 and a mud drain respectively. Port 15, the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com