Water-conducting and pressure-releasing type composite well wall of vertical shaft and construction method thereof

A technology of shaft wall and vertical shaft, which is applied in the directions of drainage, shaft equipment, earth-moving drilling and mining, etc., can solve the problems of large amount of shaft excavation, insignificant waterproof effect, large thickness of shaft wall structure, etc., and achieves simple structure and reduced size The effect of water pressure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

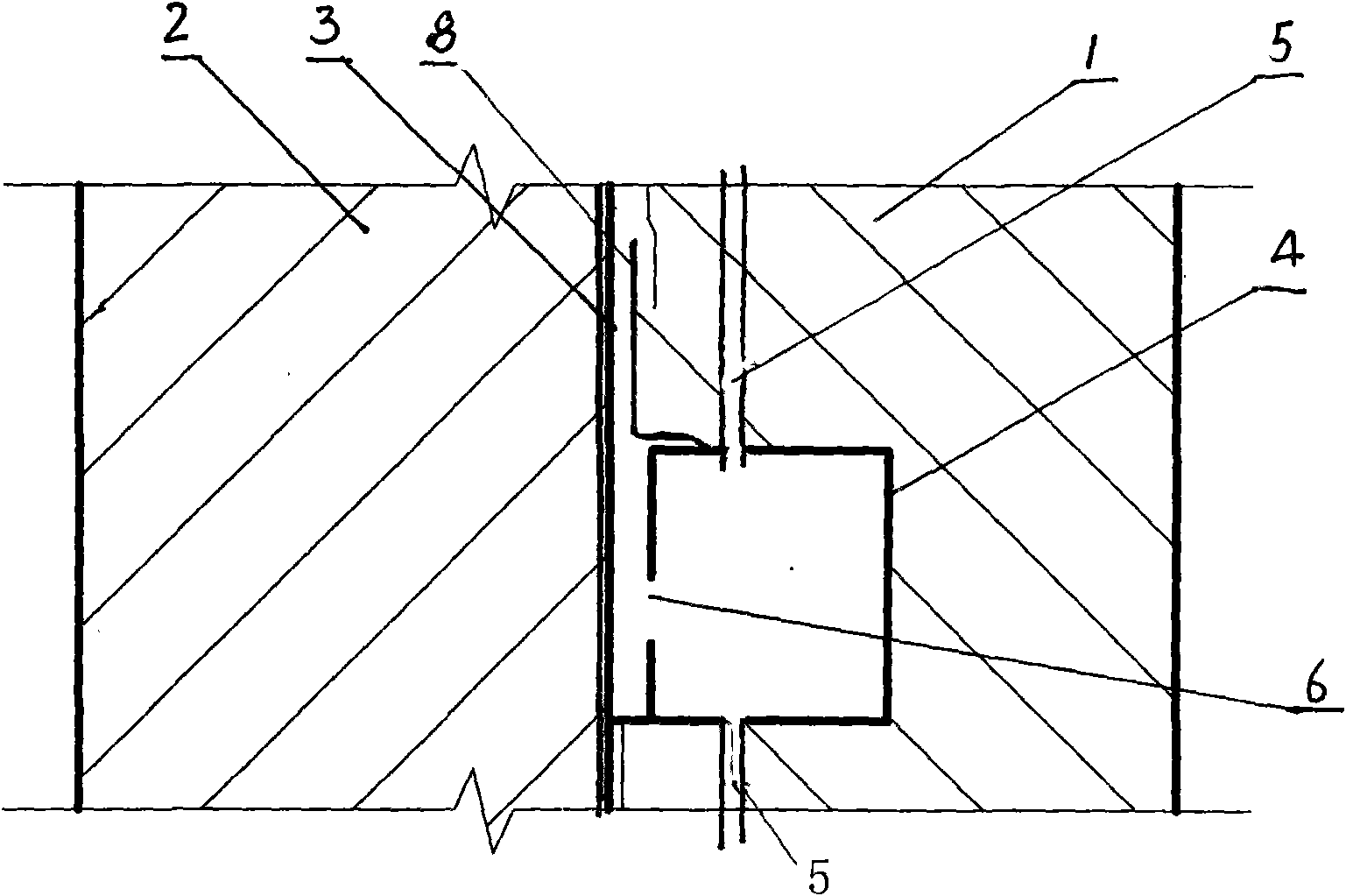

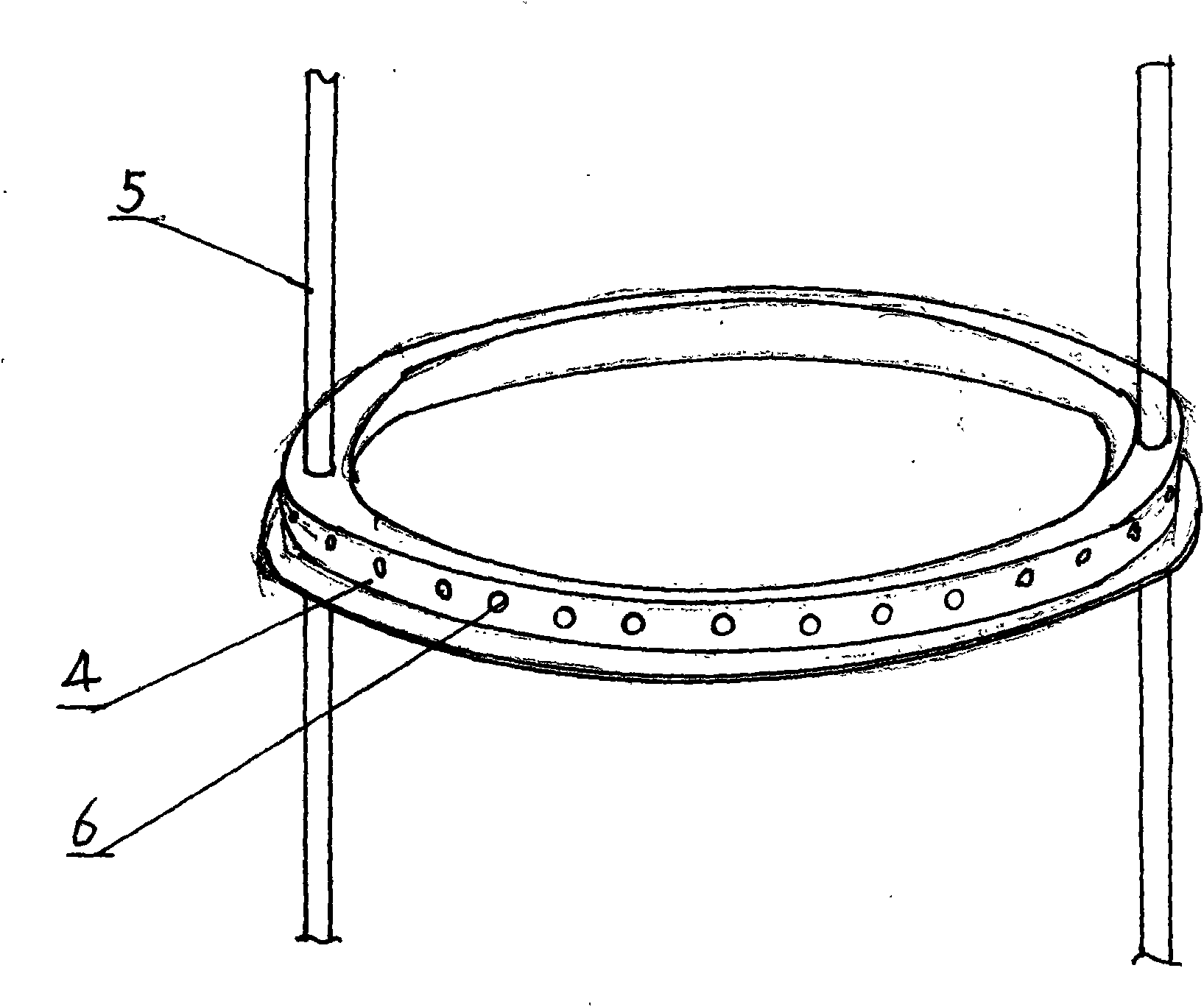

[0017] see figure 1 , figure 2 and image 3 , the present embodiment is a composite well wall composed of inner wall 1, waterproof interlayer 3 and outer wall 2, and a circle of water guide groove 4 is pre-buried on the height of each water seepage layer of inner wall 1; water guide groove 4 is a circle of closed pipes, The outer peripheral side of the pipeline is provided with a plurality of diversion holes 6; the inner cavities of all the water guide grooves 4 are communicated with the water guide pipe 5 from top to bottom, and the bottom end of the water guide pipe 5 stretches out from the bottom of the shaft after being communicated.

[0018] The inner wall of frozen sinking shaft construction is generally constructed by the bottom-up synovial membrane method or the small formwork continuous casing wall method, and the water-guiding and pressure-relieving composite shaft wall is carried out at the same time as the above-mentioned inner wall construction.

[0019] Constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com