Method for preparing positive plate of nickel hydrogen battery

A nickel-metal hydride battery and positive electrode technology, which is applied in the direction of alkaline battery electrodes, etc., can solve the problems of difficulty in ensuring the consistency of the electrode sheet, the inability to accurately control the amount of powder, and the low degree of automation, so as to improve the efficiency of powder feeding and avoid battery damage. The risk of short circuit and the effect of reducing the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

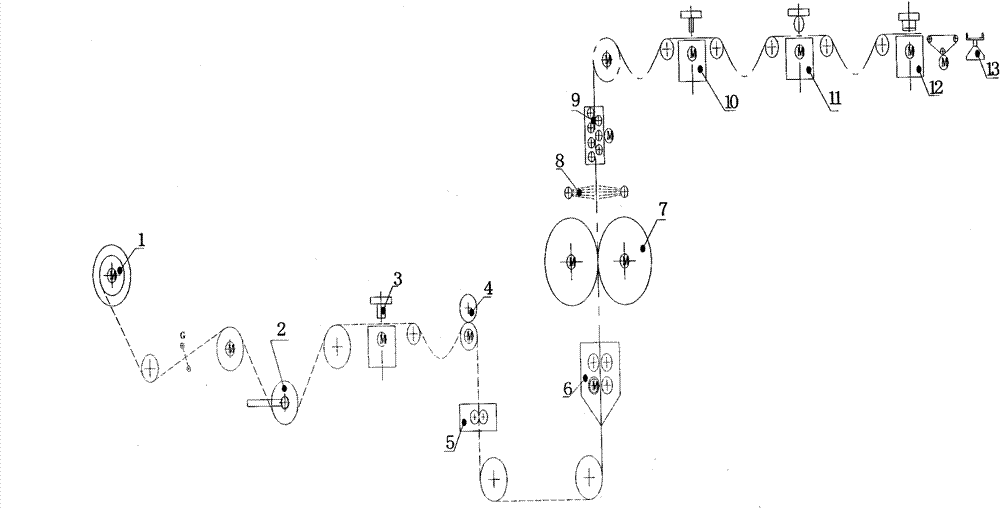

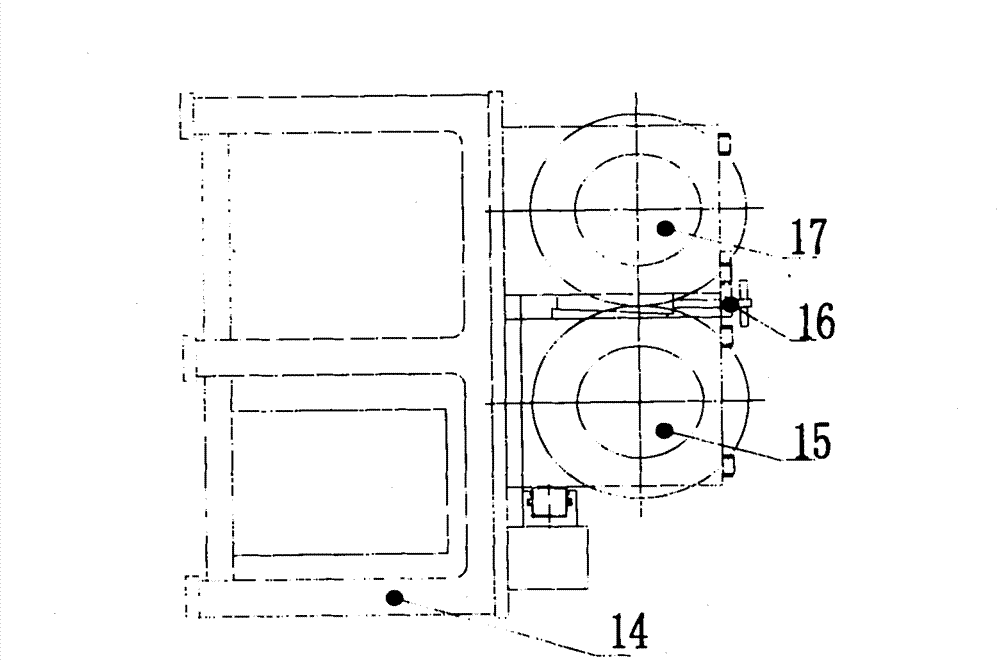

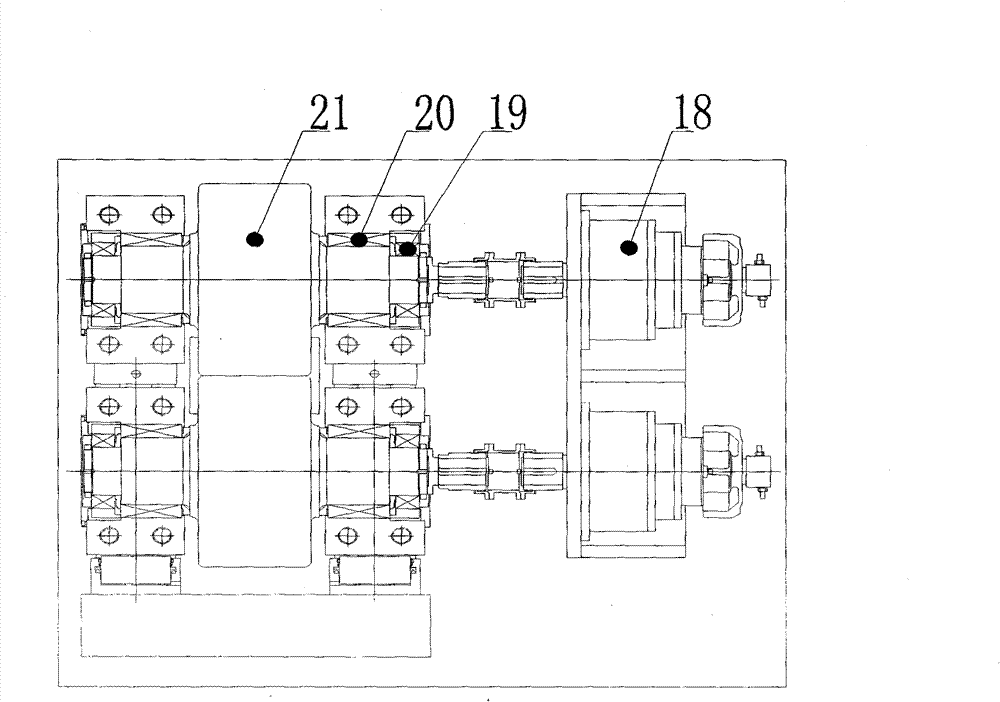

[0037] Roll nickel foam with a specification of 43×1.3mm on the disc 1, pass through the roller 2, and then enter a pair of large rollers 4 for pre-compression. After pre-compression, the thickness of the foam nickel base is 0.95mm. The slurry is brushed by the automatic gluing device 5, and the slurry is mixed by 1 kilogram of water, 0.35 kilogram of adhesive polytetrafluoroethylene, and 0.05 kilogram of conductive agent nickel powder (if a certain concentration of polytetrafluoroethylene emulsion is used) , then the amount of water can be reduced accordingly), and then the mixed powder of the active material and the additive is brushed into the base belt coated with the slurry through the upper powder box 6, and the positive active material is made of commercially available spherical nickel hydroxide Mix with cobalt powder at a ratio of 97:3, mix evenly, and put the powder on the box such as Figure 5 shown. Then immediately enter the hydraulic horizontal roller machine 7 r...

Embodiment 2

[0054] The preparation steps are the same as in Example 1. Before entering the preload, enter the automatic welding nickel wire device laser welding machine 3, weld a nickel wire 28 with a diameter of 0.3 mm on the edge of the base tape, and the other parts are the upper powder position 29. The welding method is laser welding, and the laser welding equipment of a certain company is used. The optical settings are as follows:

[0055]

laser

Spot diameter

(mm)

(mm)

out of focus

quantity

(mm)

auxiliary gas

100W-SM

5

100

0

5

Ar

[0056] The process parameters are as follows:

[0057] Power (W)

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com