Control device for machine tool

A machine tool control and control unit technology, applied in the direction of automatic control devices, motor control, feeding devices, etc., can solve the problems of cycle time increase, suppression, power consumption increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

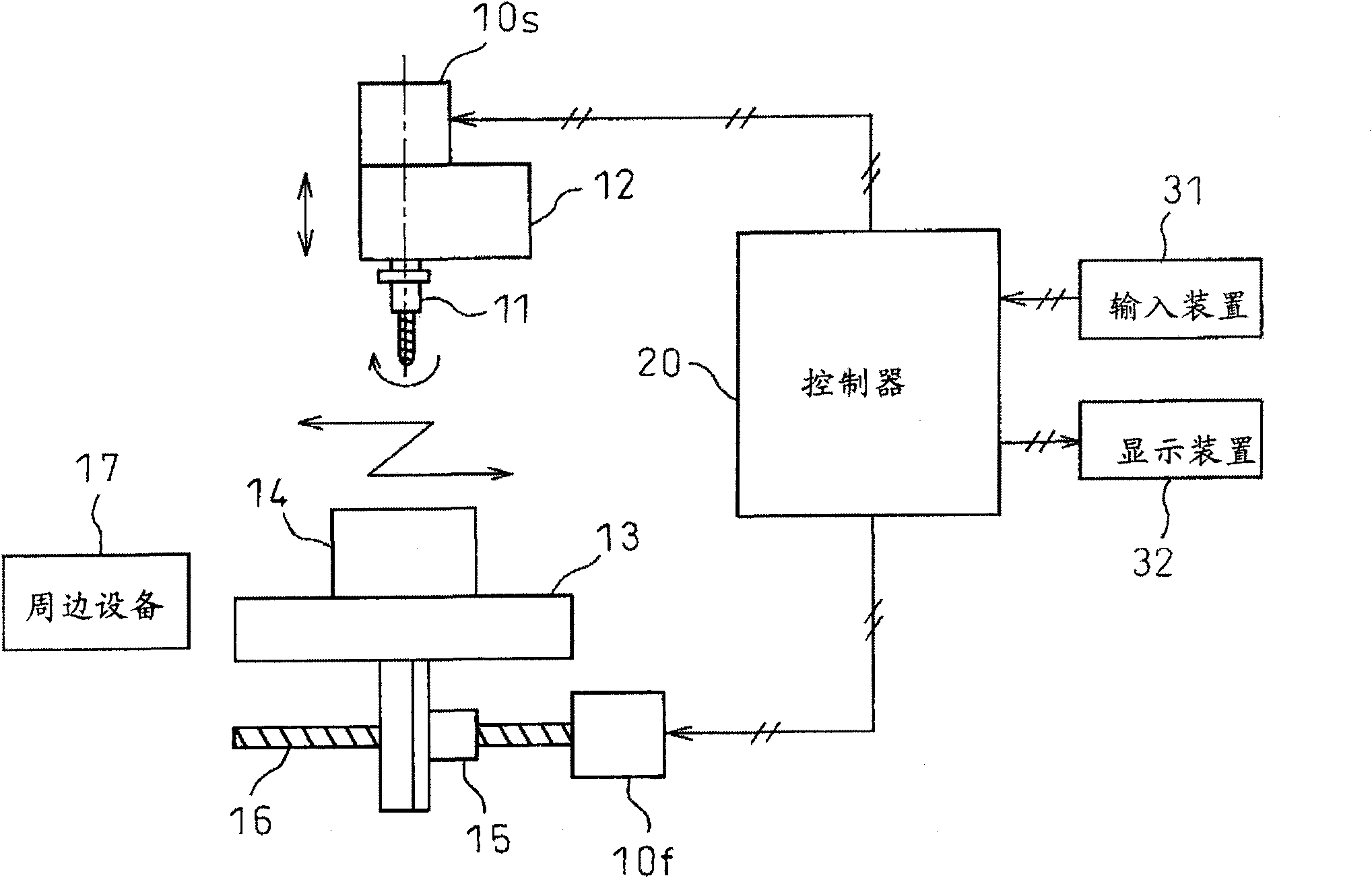

[0015] Below, refer to Figure 1 to Figure 8 Embodiments of the present invention will be described. figure 1 It is a diagram schematically showing the overall configuration of a machine tool to which the control device according to the embodiment of the present invention is applied.

[0016] figure 1 The machine tool shown is a so-called vertical machining center in which a spindle is arranged in a vertical direction. The spindle is driven to rotate by the spindle motor 10s, and the tool 11 is driven to rotate by the drive of the spindle motor 10s. The tool 11 is a cutting tool such as an end mill, a cutter, or a drill, or a grinding tool, and is detachably attached to the spindle head 12 . A table 13 is provided laterally below the tool 11 , and a workpiece 14 is fixed on the table 13 .

[0017] A ball screw 16 is bolted to the table 13 via a nut 15 . The ball screw 16 is rotationally driven by the feed axis motor 10f, and the table 13 moves in the horizontal direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com