Great ore drawing simultaneous filling non-top column shrinkage mining method

A mining method and pillar technology are applied in the field of large-scale ore drawing and synchronous filling without pillar ore retention mining, which can solve problems such as funnel blockage, improve ore recovery rate, avoid large-scale movement of surrounding rock and surface subsidence, and expand application. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

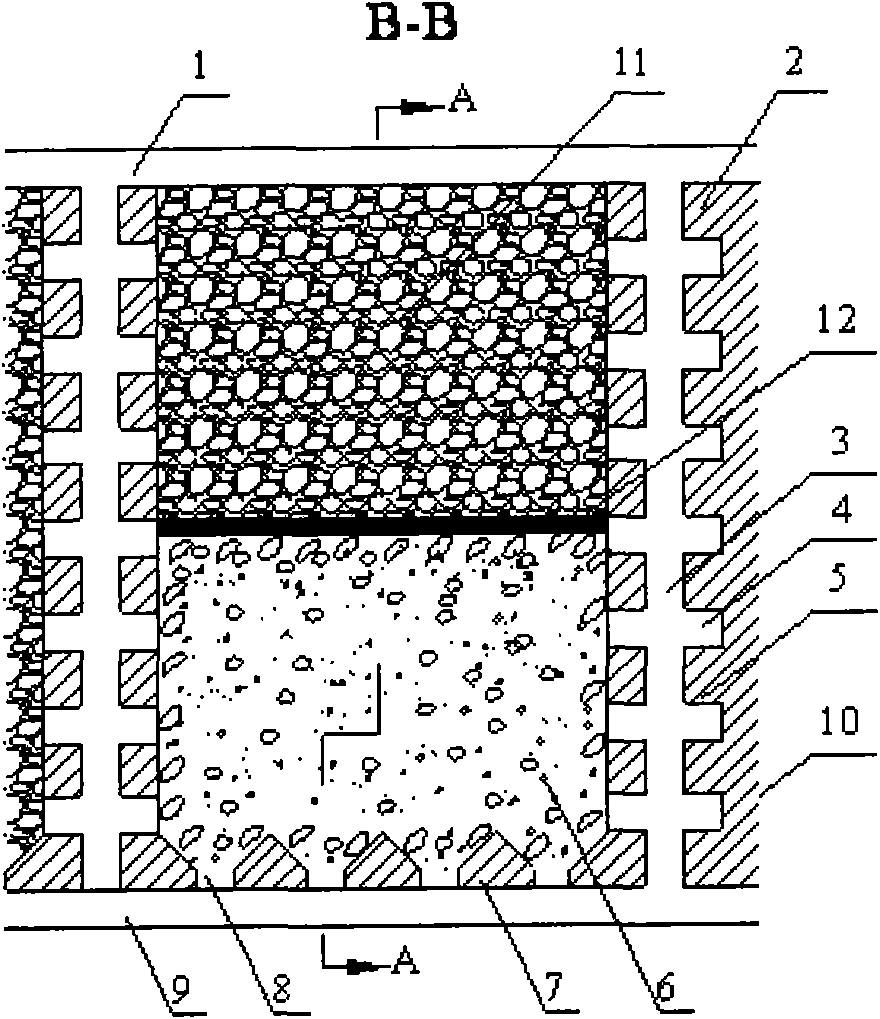

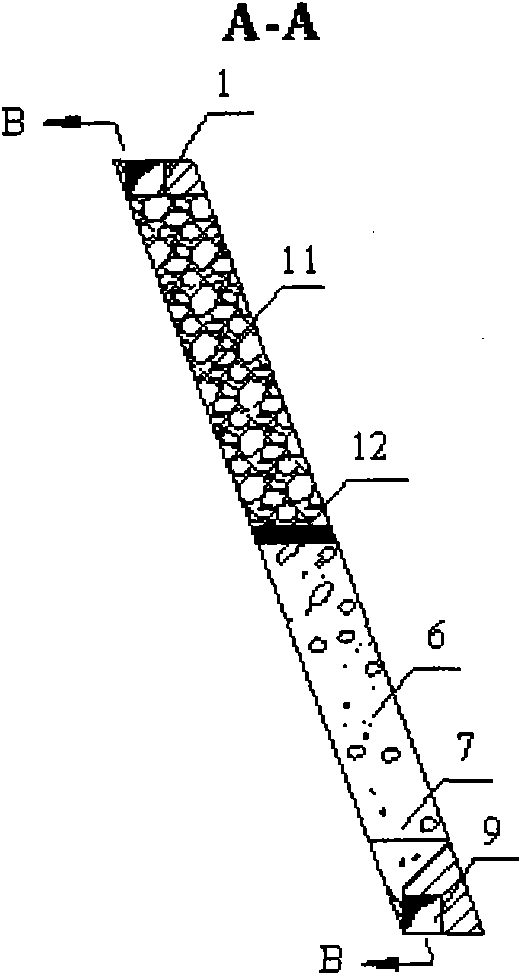

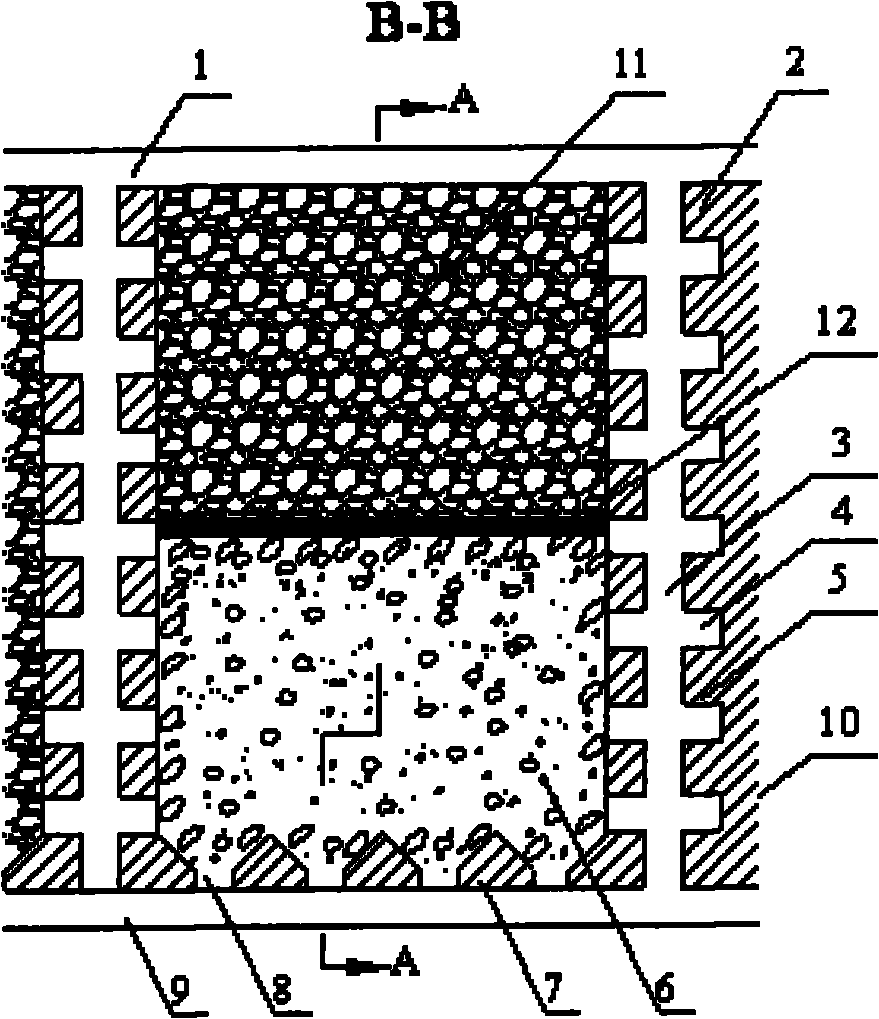

[0024] figure 1 with figure 2 It is a schematic diagram of the mining method of the present invention. A large amount of ore-drawing synchronously filling and mining method without top pillar retention described in the present invention is as follows: firstly divide the steeply inclined thin to medium-thick ore bodies with medium and stable surrounding rocks into stages, and divide the ore blocks within the stages. Firstly, the excavation specification in the inter-column 5 is 2.0×2.0m 2 The advanced patio 3 connects the lower stage transportation roadway 9 with the upper return air roadway 1; the excavation specification in the spacer 5 to the stope is 2.0×1.5m 2 Pedestrian connection roadway 4; digging 2.0×2.0m in the mine 2 The bottom-drawing roadway, the bottom-drawing roadway is used as the free surface brush to form the bottom-drawing space; the funnel 8 is formed downward in the bottom-drawing space, and the vibrating ore-drawing machine is installed at the mouth of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blockiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com