Mining method of vertical deep hole double drawing and synchronous filling stage

A technology of vertical deep hole and mining method, applied in filling, ground mining, mining equipment and other directions, it can solve the problems of collapse of surrounding rock, sacrificing mine production capacity, increasing mining precision cutting strength, etc., to simplify the structure and reduce poverty. the effect of overcoming the sharding of surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

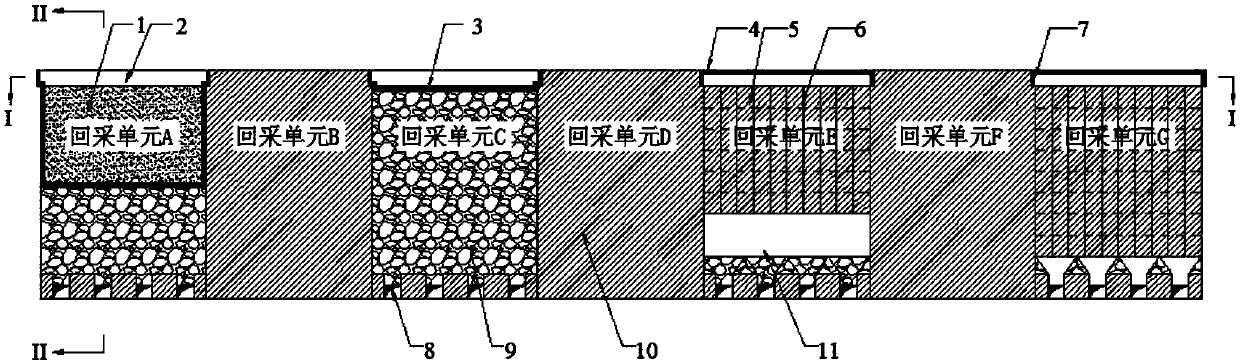

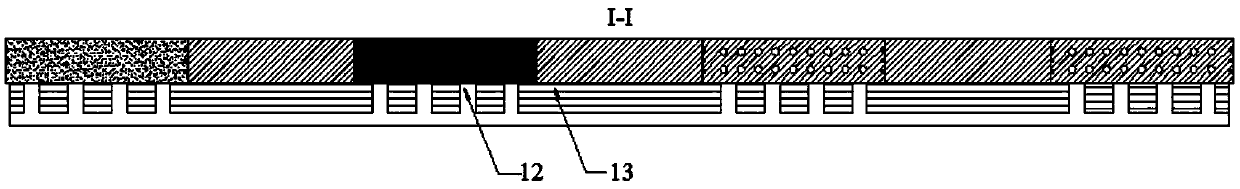

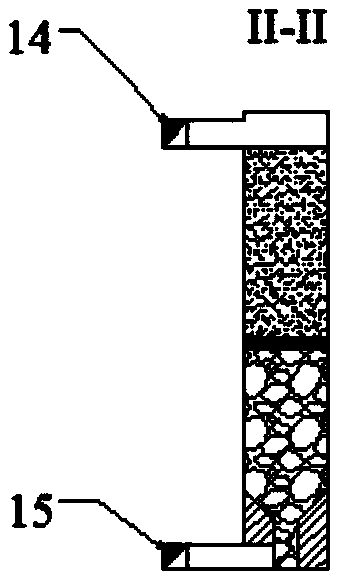

[0026] The mining method of the vertical deep hole twice drawing and filling stage synchronously, the process is as follows (refer to figure 1 , 2 , 3, 4):

[0027] The ore body is divided into stages along the dip, and the mining unit 10 is arranged along the strike, such as figure 1 Medium mining units A, B, C, D, E, F, G. The height of the mining unit 10 is generally the thickness of the ore body, the height of the mining unit 10 is 55m, the length of the mining unit 10 is 40m, and the width of the mining unit 10 is 10m.

[0028] Arrange footwall transport roadway 15 at each stage, and the size of the roadway is 4m×4m. From the footwall transportation roadway 14 of the upper stage, passing through the surrounding rock 13 through the loading roadway 12, the trench bottom structure 8 of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com